Double-roller extrusion coating production method of energy storage electrode

A technology for energy storage electrodes and production methods, applied in electrode rolling/calendering, battery electrodes, electrode manufacturing, etc., can solve problems such as reducing battery energy density, wasting materials, and difficult to control the coating thickness of positive electrode materials, and achieve stable quality , good combination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

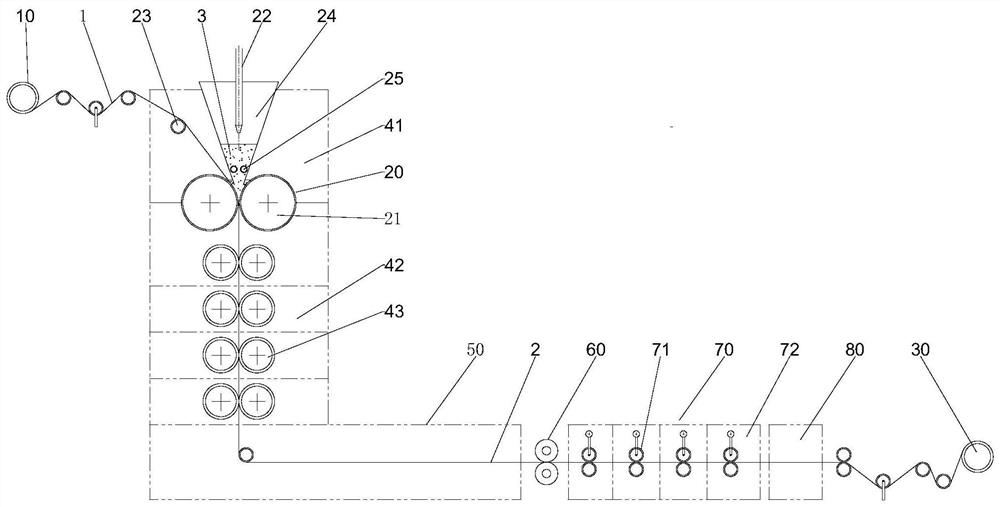

[0058] Such as figure 1 Shown is a schematic structural diagram of the twin-roll extrusion coating production equipment for the energy storage electrode in Example 1 of the twin-roll extrusion coating production method for the energy storage electrode of the present invention. The twin-roll extrusion coating production equipment of the energy storage electrode includes:

[0059] Unwinding mechanism 10: for unwinding the current collector strip 1;

[0060] Extrusion coating device 20: used for extrusion coating the electrode material layer on the current collector strip 1 and obtaining the electrode strip 2;

[0061] Winding mechanism 30: for winding the prepared electrode strip 2.

[0062] Concretely, extrusion coating device 20 comprises extrusion roller group, and extrusion roller group comprises two extrusion rollers 21 whose axes are parallel to each other; The feeding device of the electrode material 3;

[0063] Between the unwinding mechanism 10 and the winding mecha...

Embodiment 2

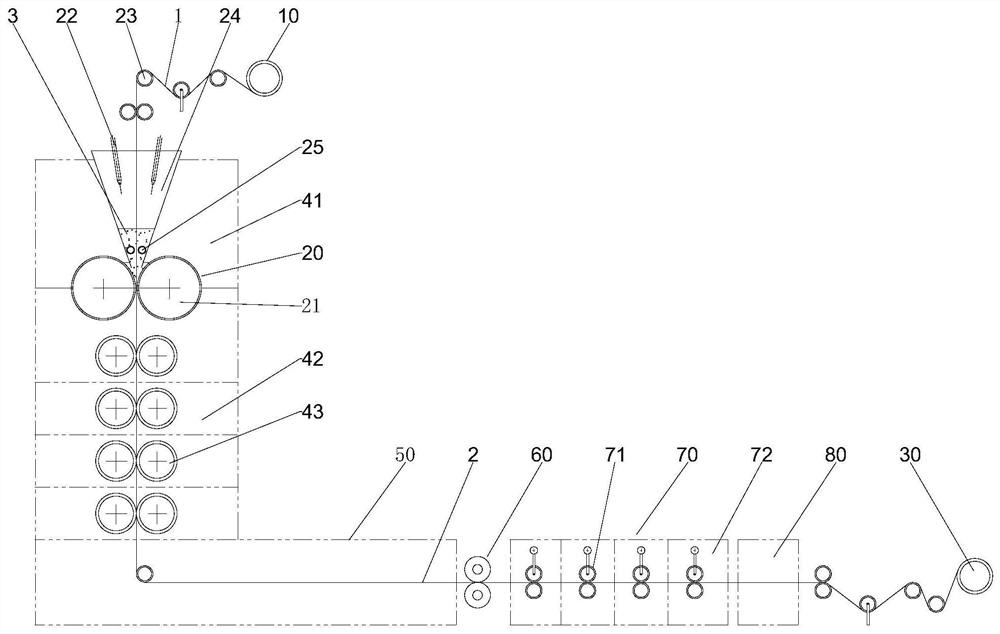

[0090] Such as figure 2 Shown is a schematic structural diagram of the twin-roll extrusion coating production equipment for the energy storage electrode in Example 2 of the twin-roll extrusion coating production method for the energy storage electrode of the present invention. The twin-roll extrusion coating production equipment of the energy storage electrode includes:

[0091] Unwinding mechanism 10: for unwinding the current collector strip 1;

[0092] Extrusion coating device 20: used for extrusion coating the electrode material layer on the current collector strip 1 and obtaining the electrode strip 2;

[0093] Winding mechanism 30: for winding the prepared electrode strip 2.

[0094] Concretely, extrusion coating device 20 comprises extrusion roller group, and extrusion roller group comprises two extrusion rollers 21 whose axes are parallel to each other; The feeding device of the electrode material 3;

[0095] Between the unwinding mechanism 10 and the winding mech...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com