Atomization core locking method and device, and aerosol generating device

A technology of locking device and atomizing core, which is applied in tobacco and other fields, can solve the problems of inconvenient maintenance and complicated structure, and achieve the effects of simplifying structure, reducing production cost and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

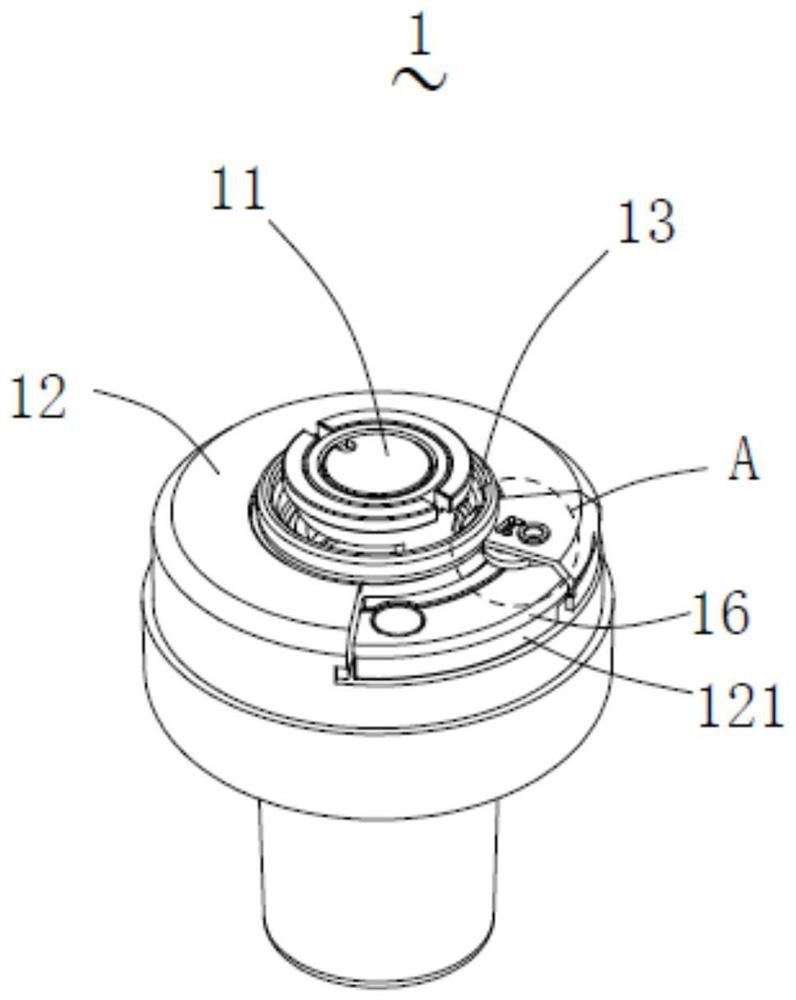

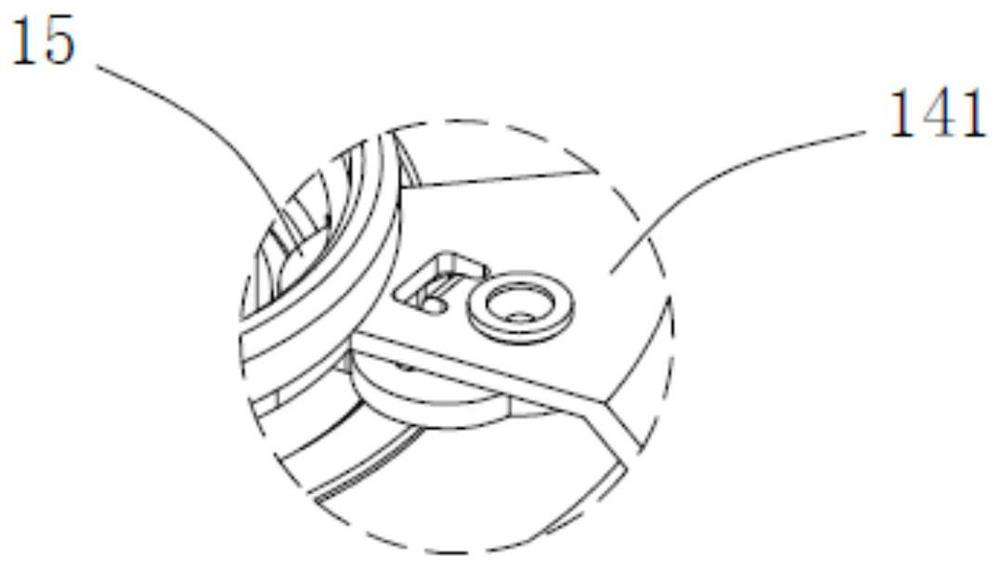

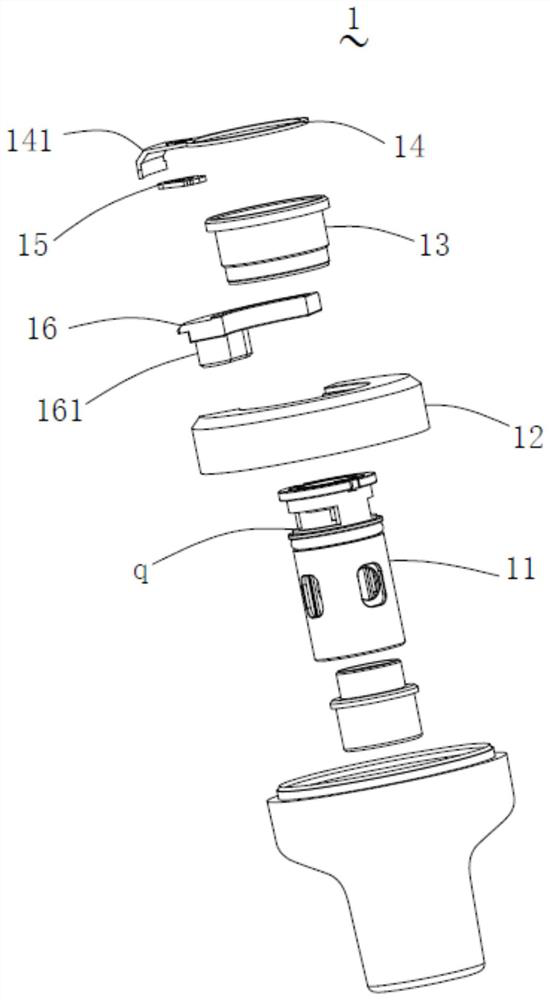

[0045] Please combine figure 1 , figure 2 and image 3 , The first embodiment of the present invention provides an atomizing core locking device 1 , including an atomizing core 11 , a base 12 , a sealing ring 13 , a rotating ring 14 , a locking plate 15 and a soft oil plug 16 .

[0046] The atomizing core 11 is plugged into the base 12, the rotating ring 14 is arranged coaxially with the base 12 and the atomizing core 11, the sealing ring 13 is arranged between the atomizing core 11 and the base 12, and the sealing ring 13 is coaxial with the atomizing core 11. The shaft is arranged, the rotating ring 14 is sleeved on the sealing ring 13, and the rotating ring 14 is connected to the sealing ring 13 in rotation.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com