YXY-type vacuum supercharging jetting and vacuum evaporation refrigerating ditype device

A vacuum and jet pump technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve problems such as incompleteness, and achieve the effect of convenient observation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

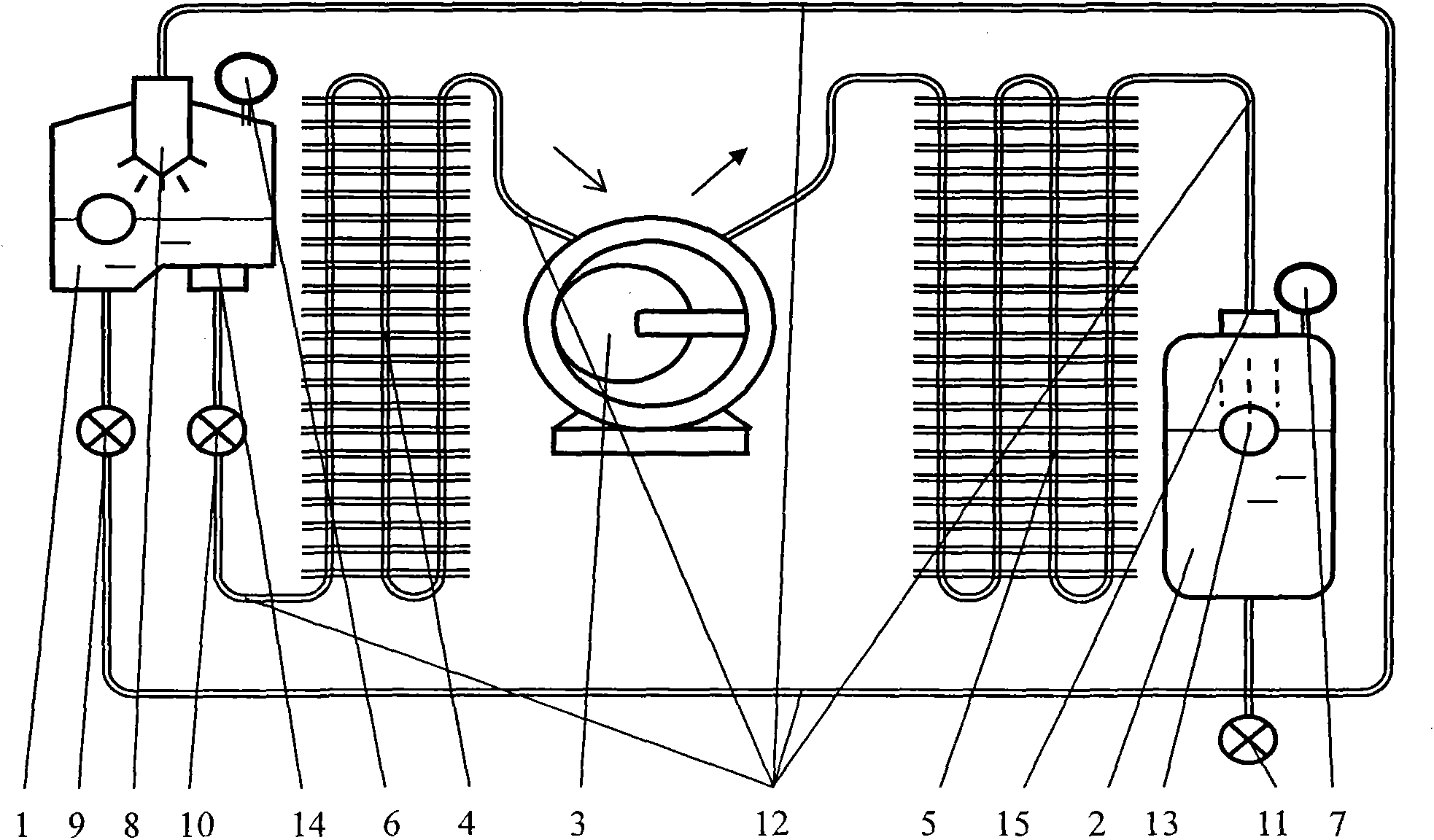

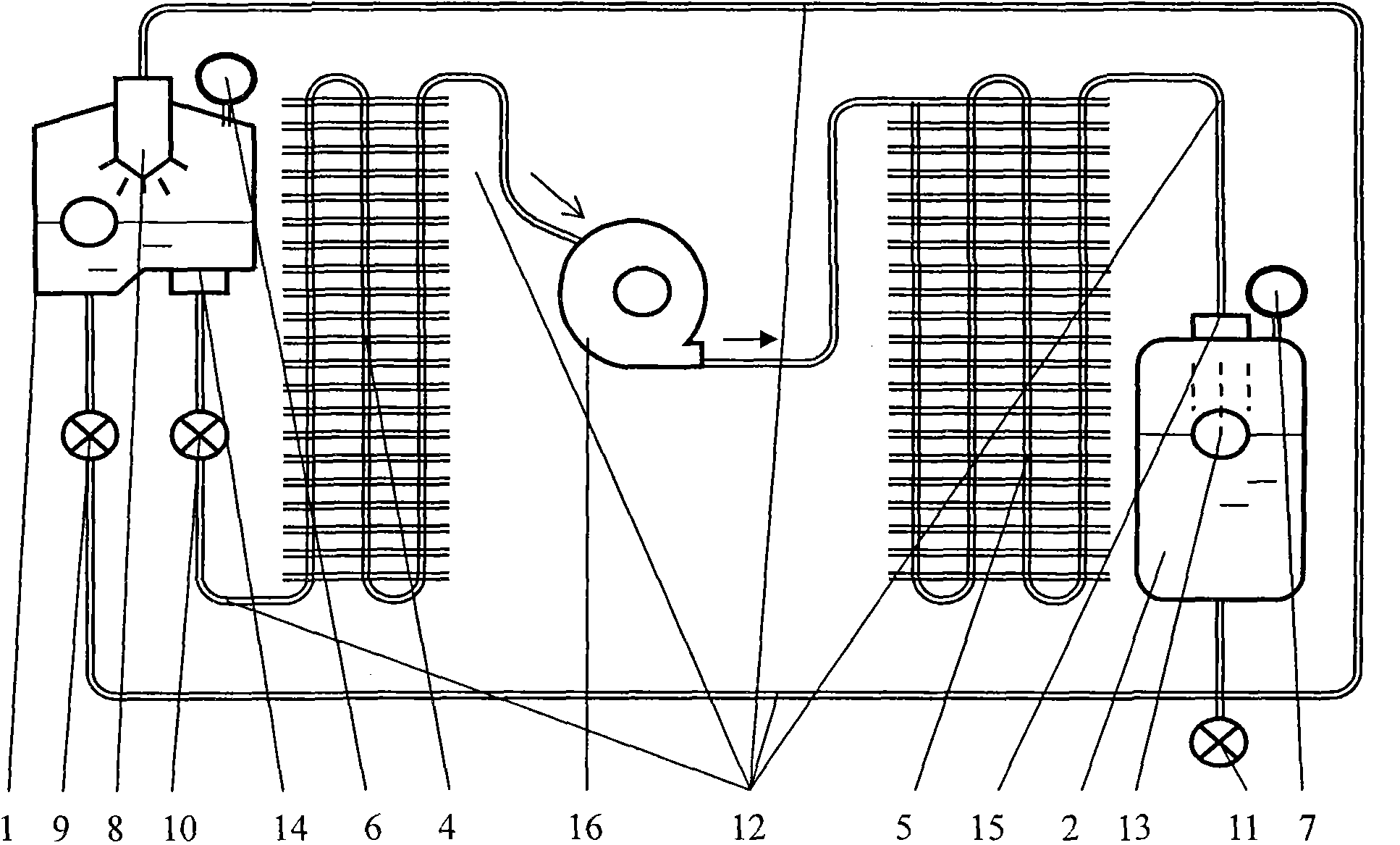

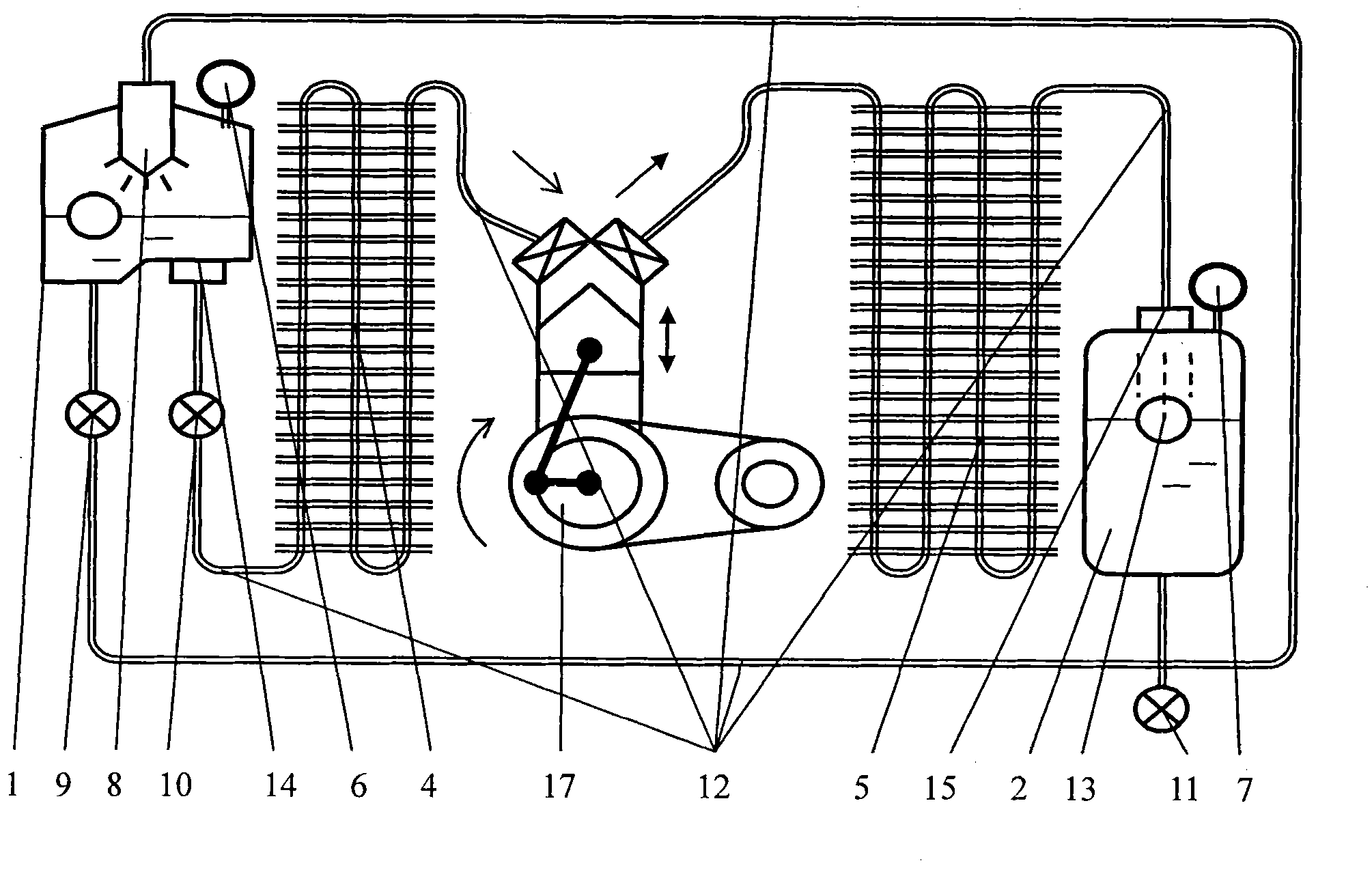

[0024] figure 1 Among them, use evaporation tank 1, storage tank 2, rotary vane vacuum / booster jet pump 3, vacuum vaporization refrigeration pipe 4, pressurized liquefaction heat release pipe 5, vacuum gauge 6, pressure gauge 7, ejector 8, and one-way valve 9, 10, drain valve 11 and pipeline 12 are connected in series in an orderly manner to form a YXY type vacuum booster injection and vacuum evaporative refrigeration type II device using a rotary vane vacuum / boost jet pump. Evaporation tank 1 is higher than storage tank 2. An oil mark 13 is arranged on the storage tank 2 . The one-way valve 9 is a normally open valve, and the one-way valve 10 is a normally closed valve.

[0025] figure 1 The working process of the refrigerating cycle in the embodiment can be briefly described as: start the rotary vane vacuum / booster jet pump 3, and generate a pressure difference between the two ends of the check valve 9 and the check valve 10. Under the action of this pressure difference,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com