Emission reduction device for unorganized emission at tail of sintering machine

A fugitive discharge, sintering machine technology, applied in the direction of furnace components, furnace types, waste heat treatment, etc., can solve the problems of substandard discharge and maintenance of the tail of the sintering machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

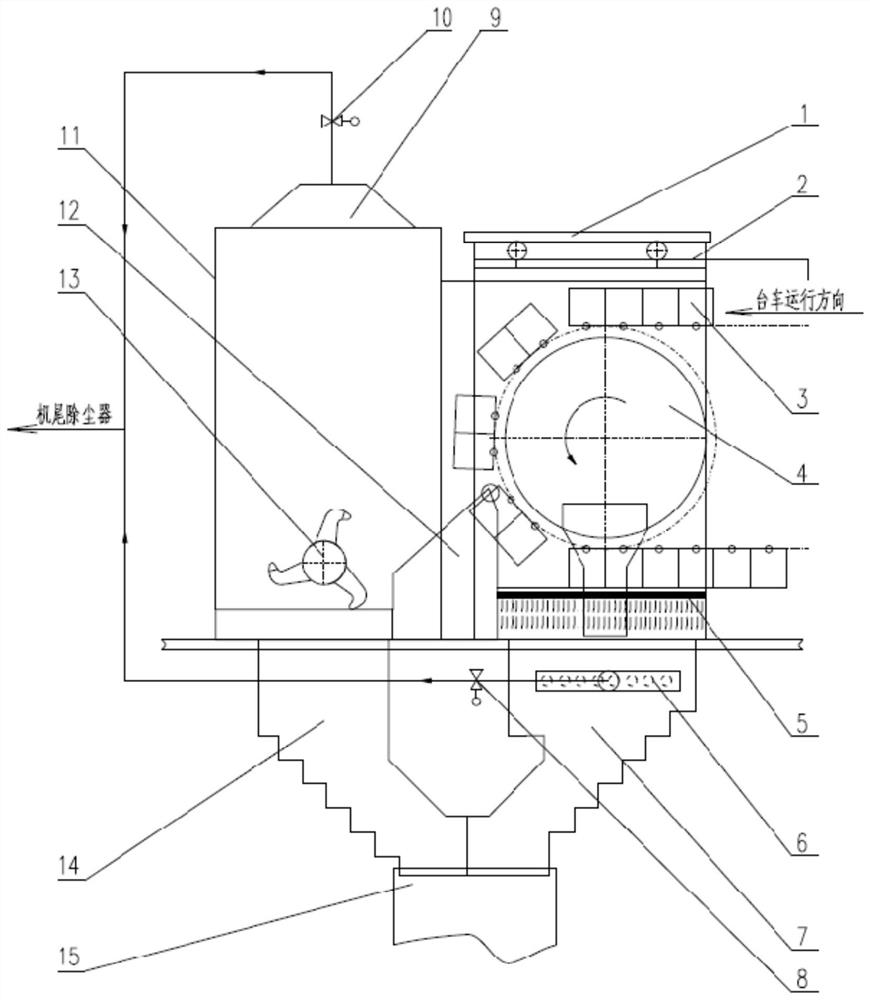

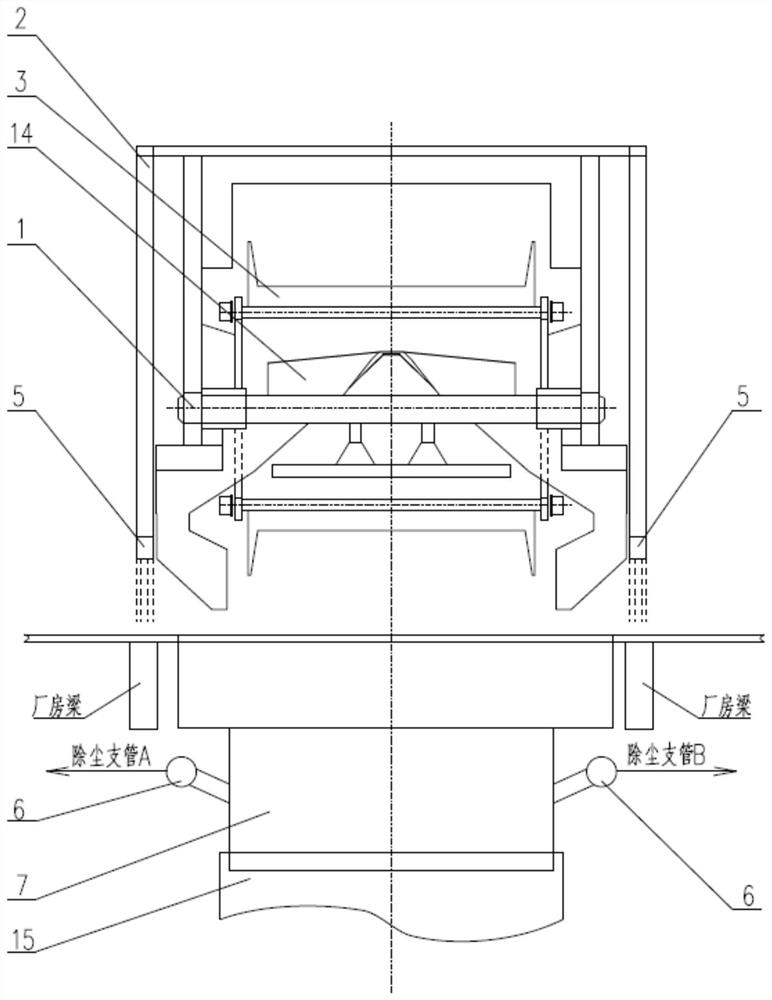

[0021] An emission reduction device for fugitive emissions at the tail of a sintering machine, including a tail star wheel moving frame 1, a sintering machine frame 2, a trolley 3, a tail star wheel 4, an air curtain machine 5, a dust suppression connecting pipe 6, and a rear chute 7. The first electric control valve 8, the top dust collection hood 9, the second electric control valve 10, the smoke hood of the single-toothed roller crusher 11, the material guide box 12, the single-toothed roller crusher 13, the front chute 14 and the ring cooler The receiving bucket 15; the sintering machine frame 2 is the main frame of the sintering system, the trolley 3 is placed on the track of the sintering machine frame 2, and circulates in the main frame, and the tail star wheel moving frame 1 is installed on the sintering machine frame 2; The tail star wheel 4 is installed inside the tail star wheel mobile frame 1, the trolley 3 enters the gear of the tail star wheel 4, and the rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com