Vacuum Precision Casting Furnace Mold Shell Lifting Device

A technology of precision casting and mold shell, applied in the field of metallurgy, can solve problems such as high personnel requirements and unfavorable product uniformity, and achieve the effects of improving production efficiency, controlling casting quality in real time, and shortening casting time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example ;

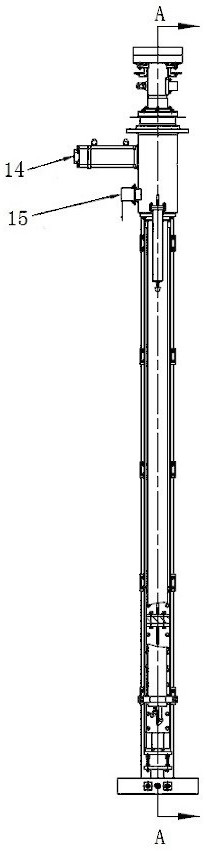

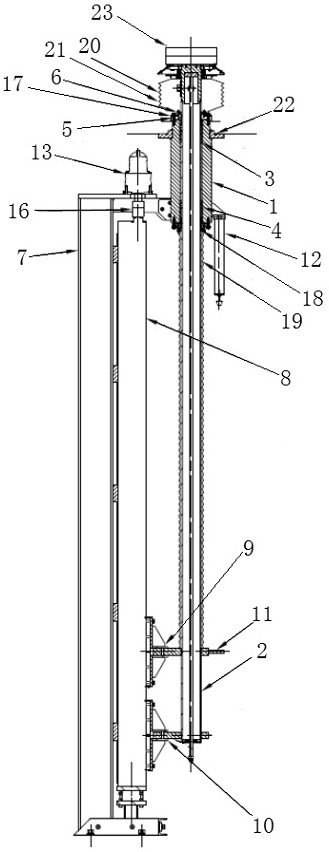

[0073] Such as figure 1 to combine figure 2 Shown, the present invention a kind of vacuum investment casting furnace formwork hoisting device, comprises:

[0074] Fixing piece 1, which passes through and is fixed on the bottom wall of the ingot cavity;

[0075] Main shaft 2, one end of which penetrates into the fixed part 1, and the other end is located outside the ingot cavity, which can move vertically in the fixed part 1 deep into or withdrawn from the ingot cavity;

[0076] The first sealing assembly is located in the ingot cavity and arranged between the fixed part 1 and the main shaft 2;

[0077] The second sealing assembly, which is located in the ingot cavity, is fixed between the fixing part 1 and the high temperature resistant telescopic protective cover 21;

[0078] Support frame 7, which is located outside the ingot cavity, is arranged in a vertical direction, and its upper part is fixed on the fixture 1;

[0079] The power source 14 is fixed on the top of the...

no. 2 example ;

[0091] continue to refer figure 1 to combine figure 2 Shown, the present invention a kind of vacuum investment casting furnace formwork hoisting device, comprises:

[0092] Fixing piece 1, which passes through and is fixed on the bottom wall of the ingot cavity;

[0093] Main shaft 2, one end of which penetrates into the fixed part 1, and the other end is located outside the ingot cavity, which can move vertically in the fixed part 1 deep into or withdrawn from the ingot cavity;

[0094] The first sealing assembly is located in the ingot cavity and is arranged between the fixed part 1 and the main shaft 2, including the sealing ring positioning gasket 3 fixed in the fixed part 1 and the shaft sealing ring 4, and sleeved on the fixed part 1 The dust-proof sealing ring 18 of two ports, the dust-proof ring retaining ring 6 covers are contained on the dust-proof sealing ring 18;

[0095] The second sealing assembly, which is located in the ingot cavity, is fixed between the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com