Intelligent mechanical type live working traction rope safety throwing device

A technology of live work and intelligent machinery, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of cumbersome steps, low safety, and long time for hanging pulleys, shorten throwing time, ensure personal and equipment safety, and be easy to maintain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

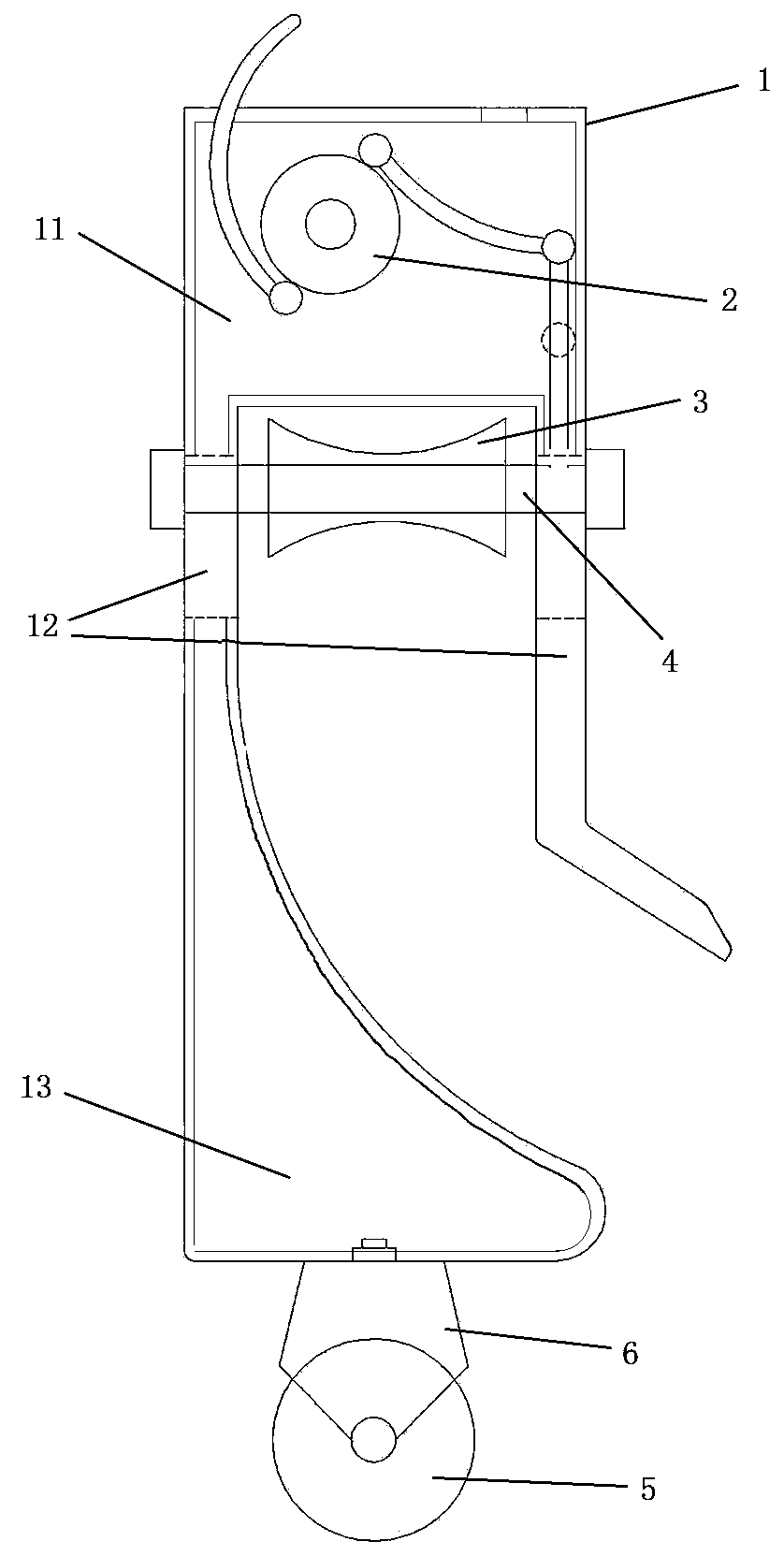

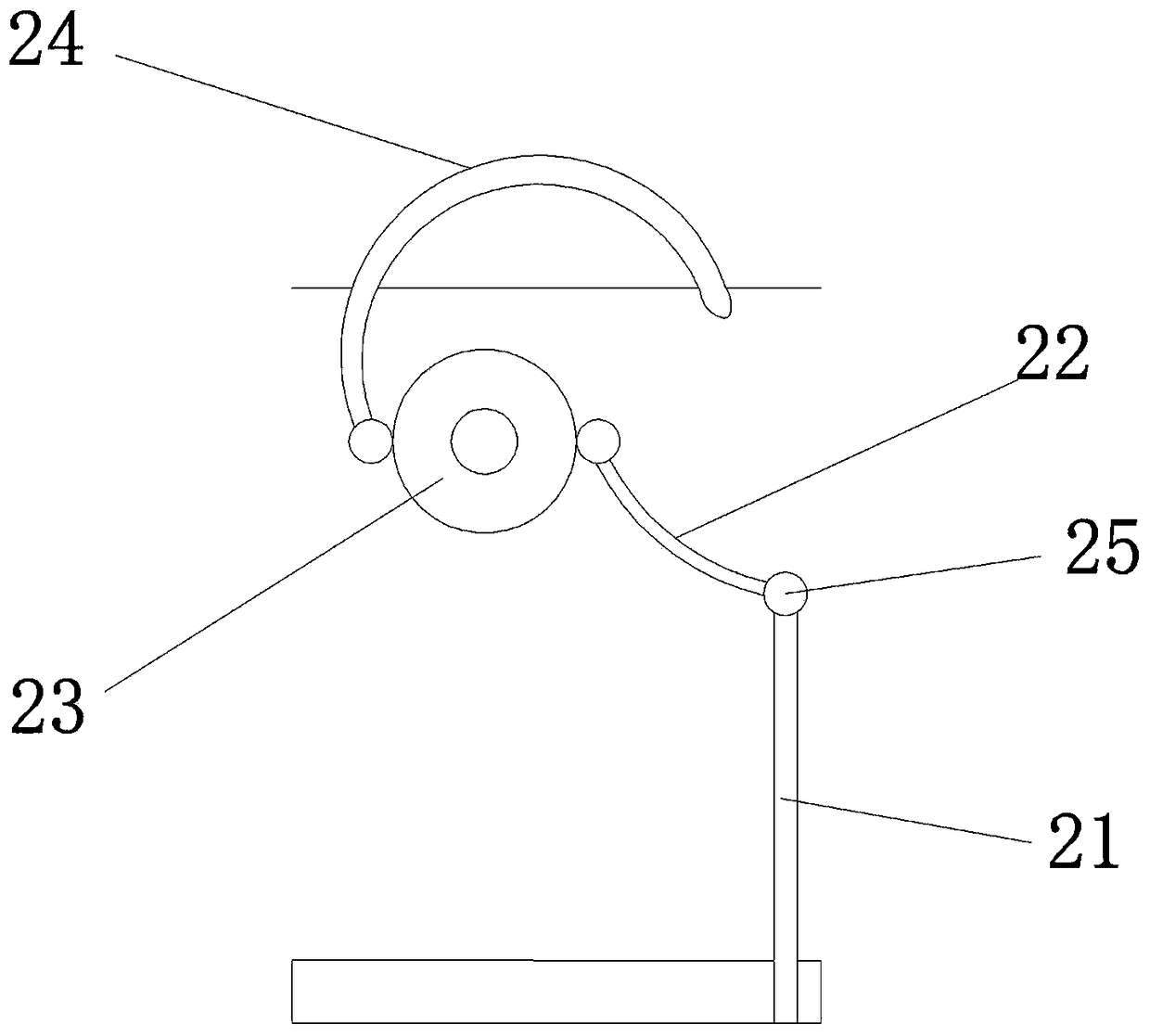

[0016] Example: An intelligent mechanical traction rope safe throwing device for live working, consisting of a support frame 1, a transmission device 2, an upper pulley 3, a pulley shaft 4, a lower pulley 5 and a pulley frame 6. The support frame 1 is welded by steel plates The overall structure consists of an upper frame 11, a middle frame 12 and a lower frame 13. The upper frame 11 has a rectangular groove structure, and the transmission device 2 is fixedly connected in the rectangular groove structure. The middle frame 12 includes two chutes with sliding grooves. The upper pulley 3 is connected to the chute through the pulley shaft 4, the lower frame 13 is a triangular groove, and the lower pulley 5 is fixedly connected to the lower end surface of the triangular groove through the pulley frame 6; the upper pulley 3 is two thin in the middle A cylindrical pulley with a thick end. Both ends of the upper pulley 3 and the pulley shaft 4 are bolted between two side plates with chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com