Lining plastic pipe manufacturing equipment and method

A technology for manufacturing equipment and plastic pipes, applied in mechanical equipment, pipes, rigid pipes, etc., can solve problems such as difficulty in interpenetration construction, and achieve the effects of convenient construction, good hardness, and hardness and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

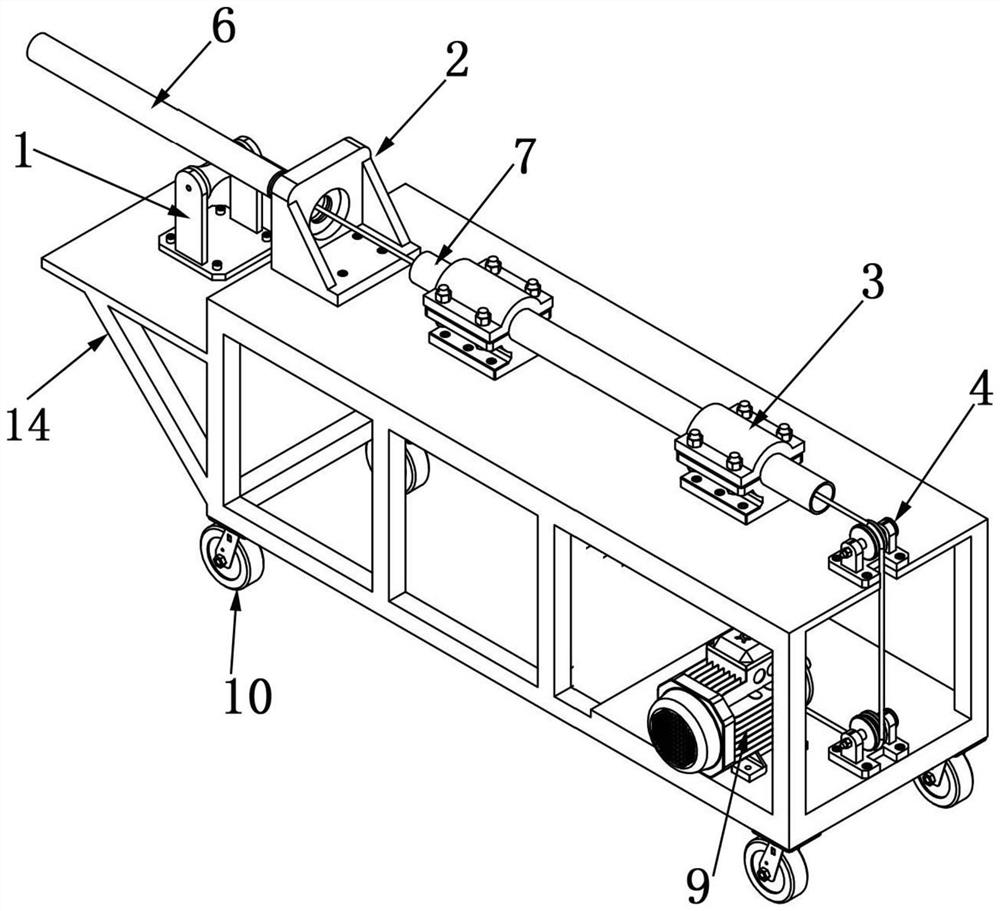

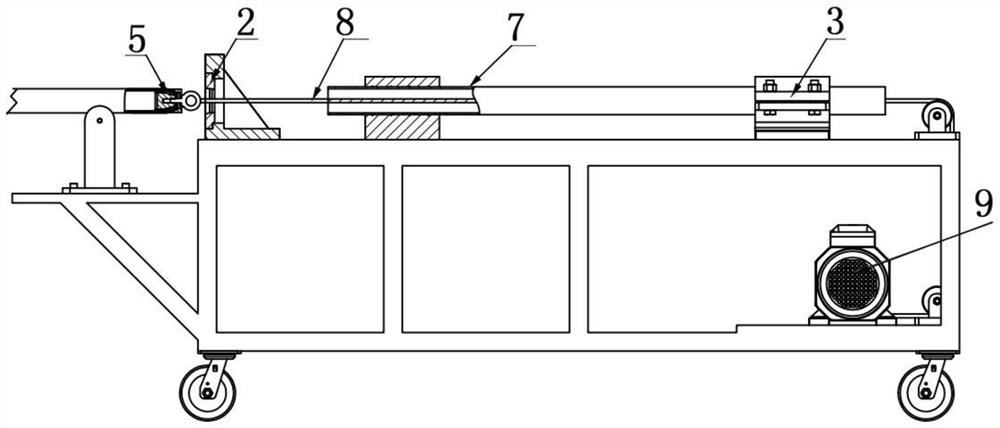

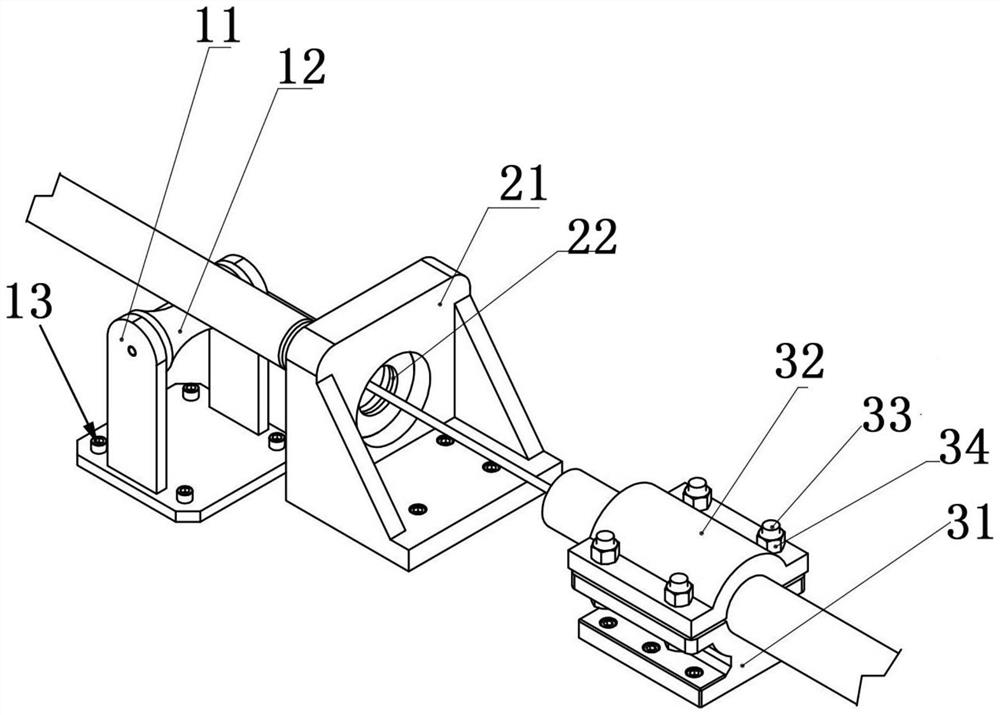

[0031] Example: Control Figure 1-7

[0032] A manufacturing equipment for lined plastic pipes, comprising a frame 14 and a positioning mechanism 1, a diameter reducing mechanism 2, a fixing mechanism 3 and a traction mechanism arranged on the frame 14, the frame 14 is welded by channel steel and plates made. The positioning mechanism 1 is used to support the stable plastic pipe 6, and the fixing mechanism 3 is used to fix the lining steel pipe 7 on the frame 14. The plastic pipe 6, the reducing mechanism 2 and the lining steel pipe 7 are located on the same horizontal straight line.

[0033] The traction mechanism includes a traction fixture 5, a traction rope 8, a fixed pulley assembly 4 and a hoist 9, the traction fixture 5 is fixedly assembled on an end port of the plastic pipe 6 close to the diameter reducing mechanism 2, and one end of the traction rope 8 is fixedly connected with the traction fixture 5, The other end of the traction rope 8 passes through the inner spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com