Propeller governor beta valve assembly

A technology of valve components and governors, which is applied to propellers, aircraft parts, transportation and packaging, etc., can solve the problems of waste of land resources, low utilization rate of land resources, long runways, etc., and achieve simple propeller structure, shorten taxiing runways, Good effect on flight safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

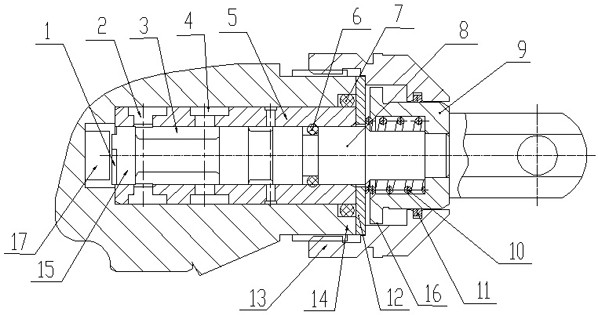

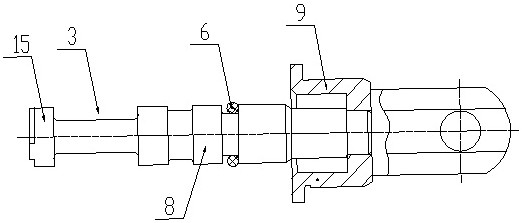

[0013] Such as figure 1 and figure 2 As shown, this embodiment includes a bushing 5 , a valve 8 , a return spring 10 , a U-shaped fork 9 with a step and a central hole, and a cap 13 . One end of the valve 8 is provided with a small-distance end block 15, and the other end is fixed with a U-shaped fork 9. The bushing 5 is press-fitted in the circular mounting port 14 protruding from the governor housing, and the port is press-fitted with an adjusting washer with the same diameter as the circular mounting port 14 protruding from the governor housing by the cap 13 12. Adjust the relative position of the small-distance end plug 15 of the valve and the high-pressure oil outlet 2 of the bushing by adjusting the washer 12. Valve 8 has one end of small-distance end plug 15 and is assembled in the bushing 5 with a micro-gap, and the valve 8 and bush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com