A direct-drinking cup lid and preparation method thereof

A direct-drinking, cup lid technology, applied in the field of cup lids, can solve problems such as easy spillage, and achieve the effect of satisfying the feeling of comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

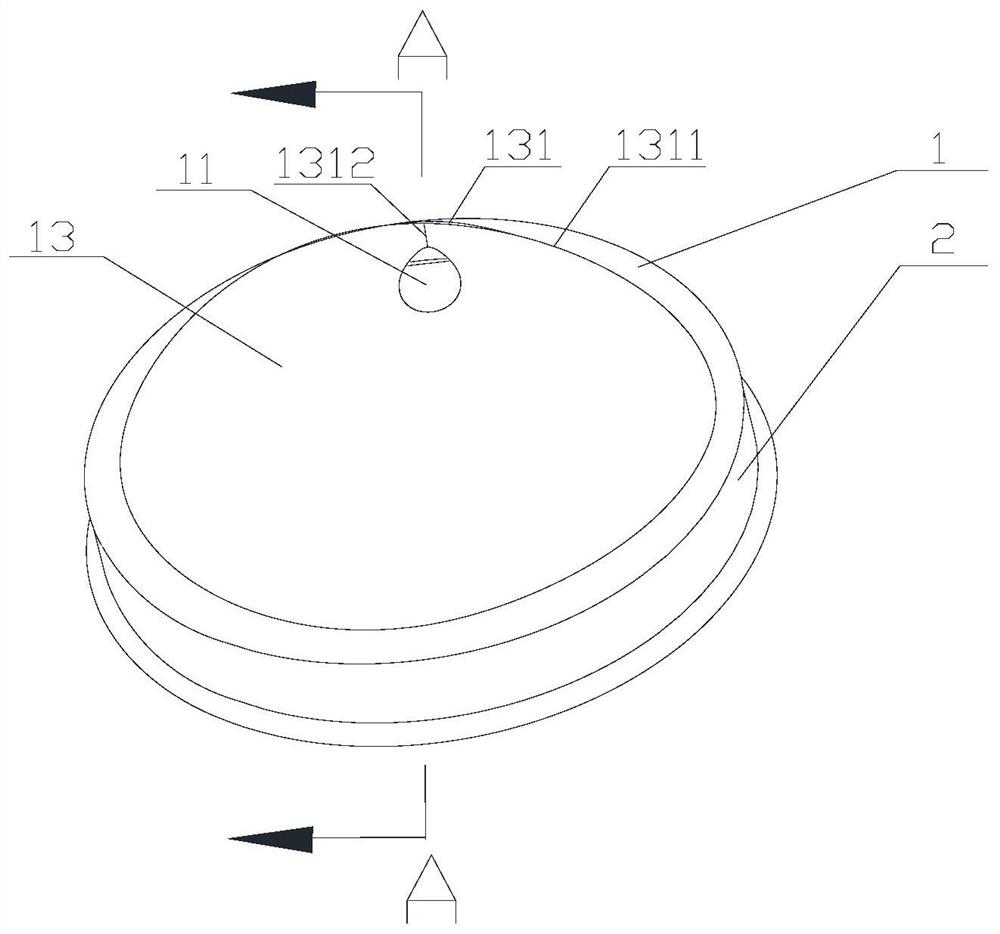

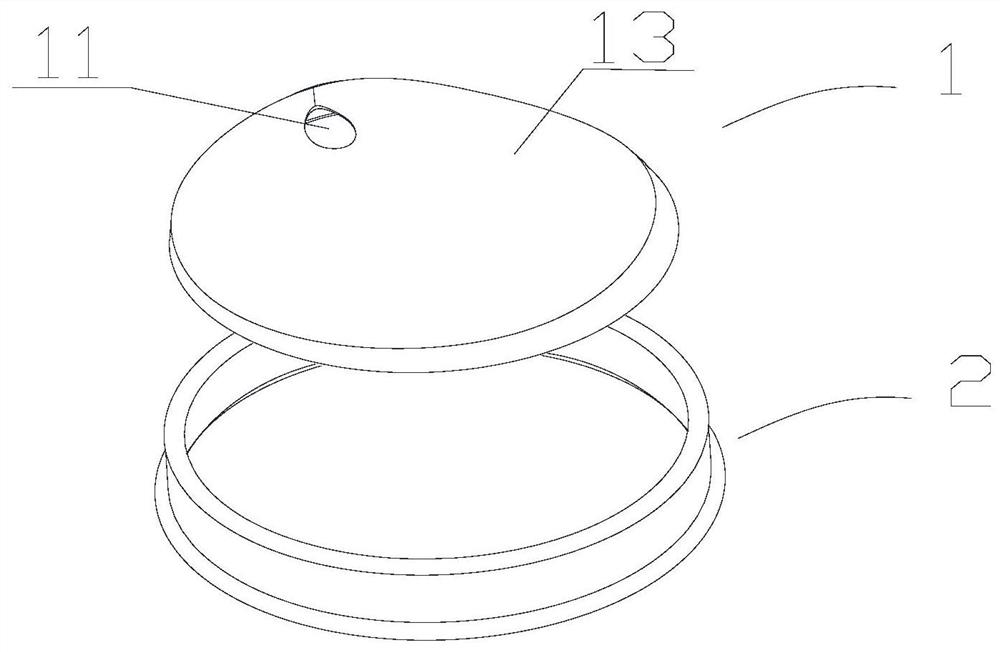

[0037] see Figure 1 to Figure 4 As shown, a preparation method of a direct-drinking cup lid comprises the following steps:

[0038] S1. Die cutting the raw material into a semi-finished product 10, and the semi-finished product 10 is provided with a through hole 12; S2. The semi-finished product 10 provided with the orifice 12 is formed into an integrated closed cover 1 by an extrusion process, wherein the orifice 12 is folded. Extrusion into oblique cut 11; S3. The closure cover 1 has an uneven surface 13, and the oblique cut 11 is arranged on the uneven surface 13 at an oblique angle; S4. The closure cover 1 and the cover ring arranged on the edge of the closure cover 2 is fixedly connected to form a lid cavity 3 that closes the cup mouth.

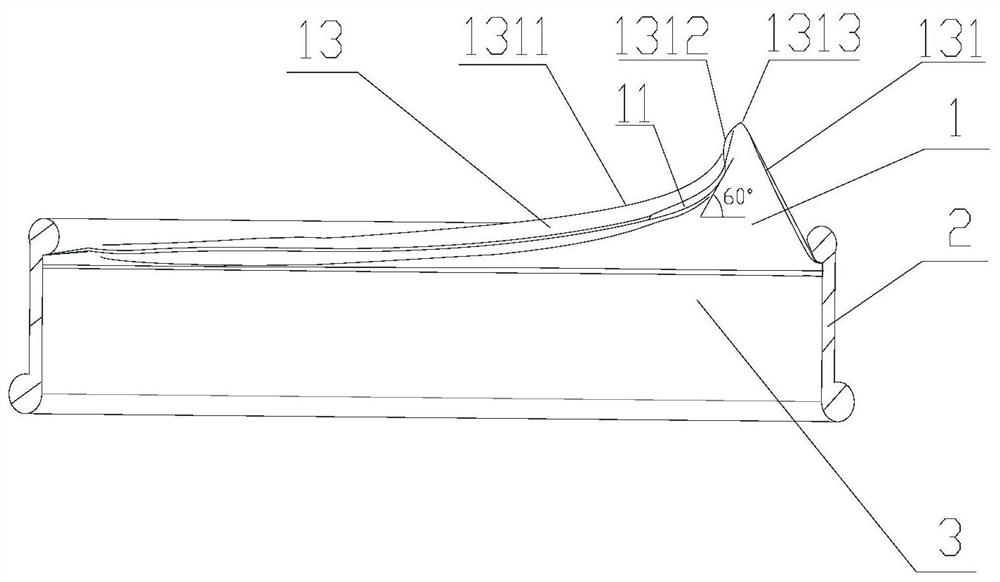

[0039] It should be noted that if Figure 4 As shown, in this embodiment, the raw material in S1 is a paper raw material, which is processed into a semi-finished product 10 by a flat die-cutting machine. The semi-finished product 10 i...

Embodiment 2

[0048] Referring to Example 1, the difference from Example 1 is that see Figure 5 and Image 6 As shown, the oblique incision 11 passes through the highest point of the ring convex wall 131, and is cut by the line fold 1311 into a first oblique incision 111 and a second oblique incision 112, and the oblique incision 11 is three-dimensional on the uneven surface 3D structure set.

[0049] As a specific implementation manner, the incision area of the first oblique incision 111 in this embodiment is greater than or equal to the incision area of the second oblique incision 112 .

[0050] It should be noted that the first oblique incision fits the upper lip, the second oblique incision fits the lower lip, and the three-dimensional 3D structure of the oblique incision is set. In this embodiment, the oblique incision angles are 45° and 135° as examples, such as Image 6 As shown, the inclination angle of the first oblique incision is 45°, the inclination angle of the second ob...

Embodiment 3

[0052] Referring to Example 1, the difference from Example 1 is that see Figure 7 and Figure 8 As shown, the uneven surface 13 of the closure cover 1 in this embodiment is a ring groove, which is gradually lowered from one place to both sides in the middle part and is surrounded by a ring groove. The uppermost part of the ring groove is provided with a ring groove. For the line crease 1311, the inclination angle of the oblique cut 11 in this embodiment is 30° as an example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com