Finished product bin system of container-type asphalt mixing station

A technology of asphalt mixing plant and finished product silo, which is applied in the field of asphalt finished product silo, which can solve the problems of inaccurate control, low feeding efficiency, easy spillage, etc., and achieve the effect of simple operation, convenient control, and improved feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

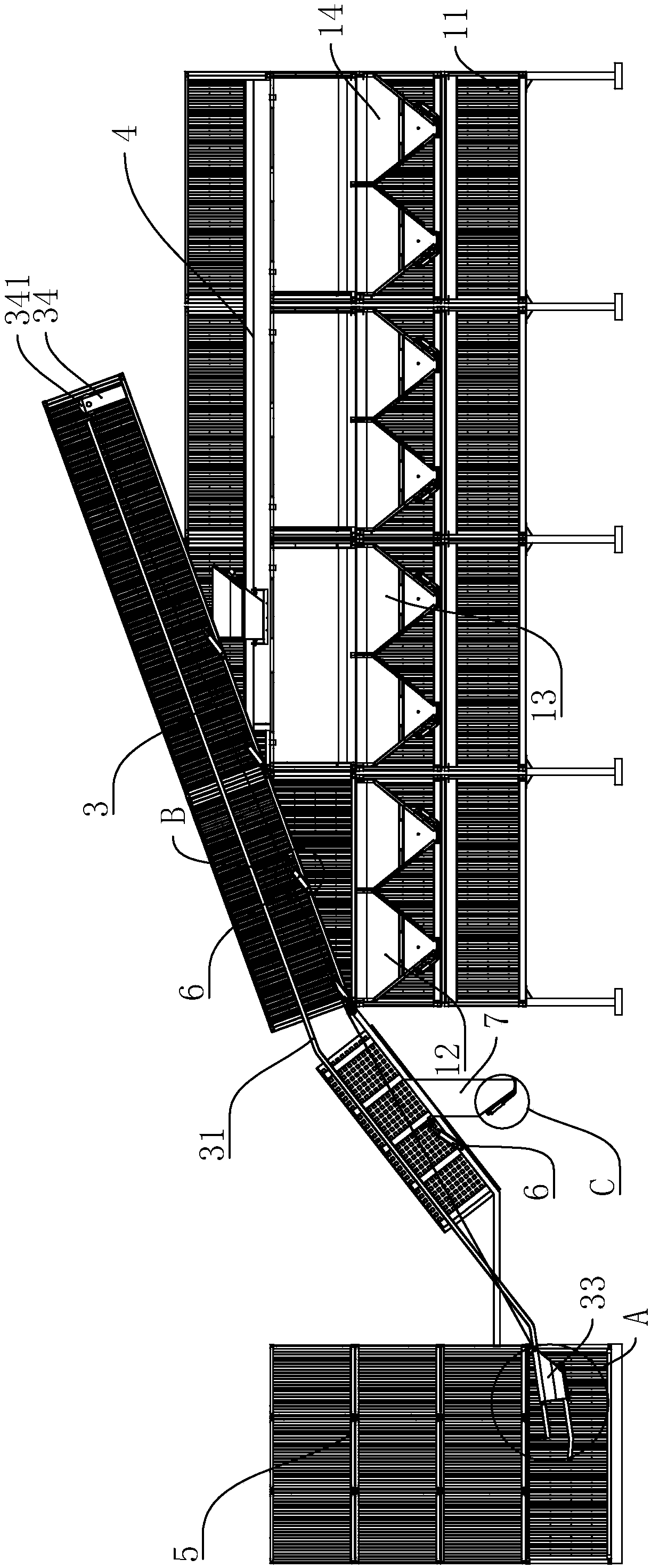

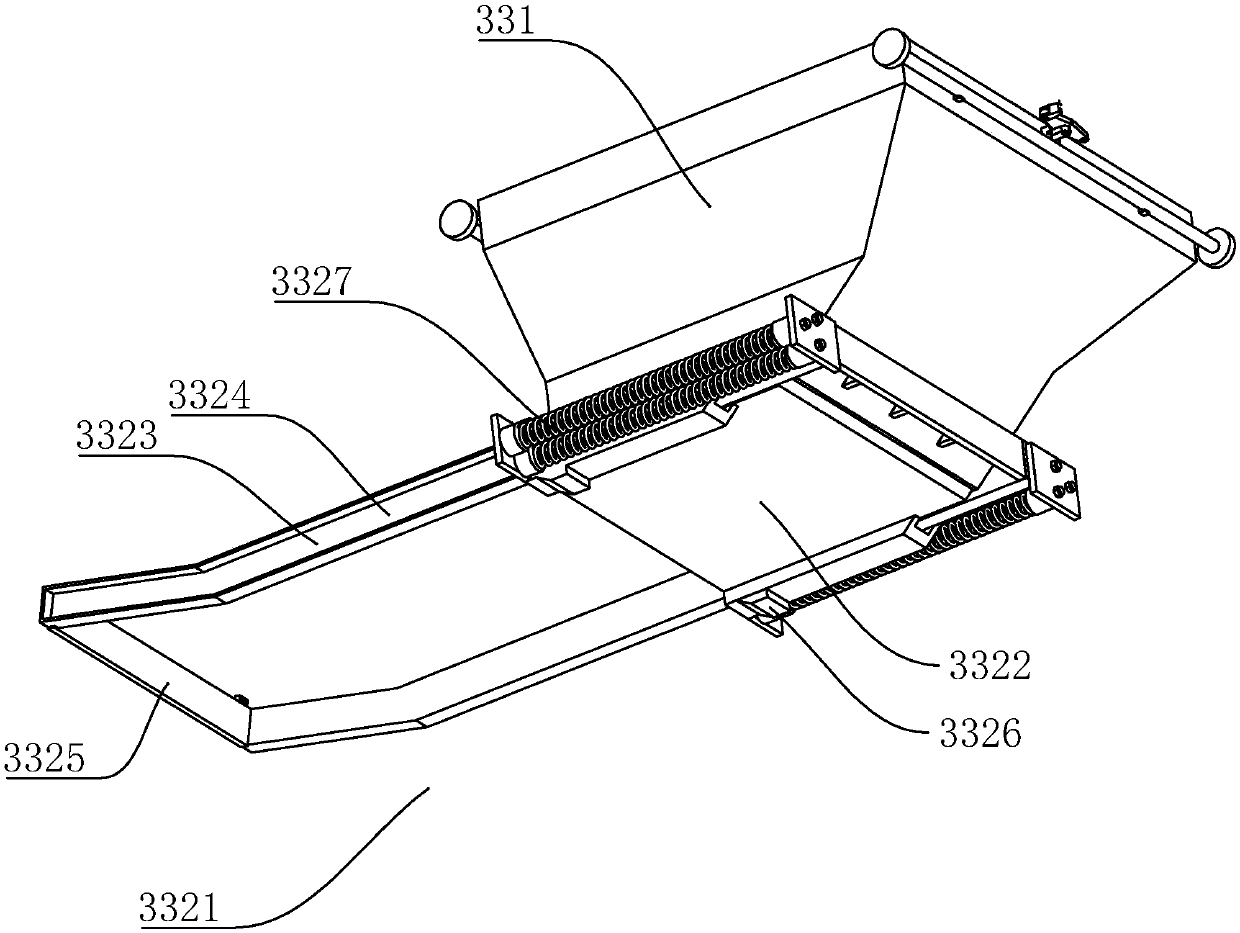

[0052] Embodiment: A finished product silo system of a container-type asphalt mixing plant, such as figure 1 As shown, including the control center, the control center is used to control the operation of the entire finished product silo system; the container-type finished product silo 1 is used to store asphalt material for backup; the finished material lifting system 2 is used to receive the mixed material in the main mixing building 5 The asphalt material is sent to each finished product silo of the container-type finished product silo 1.

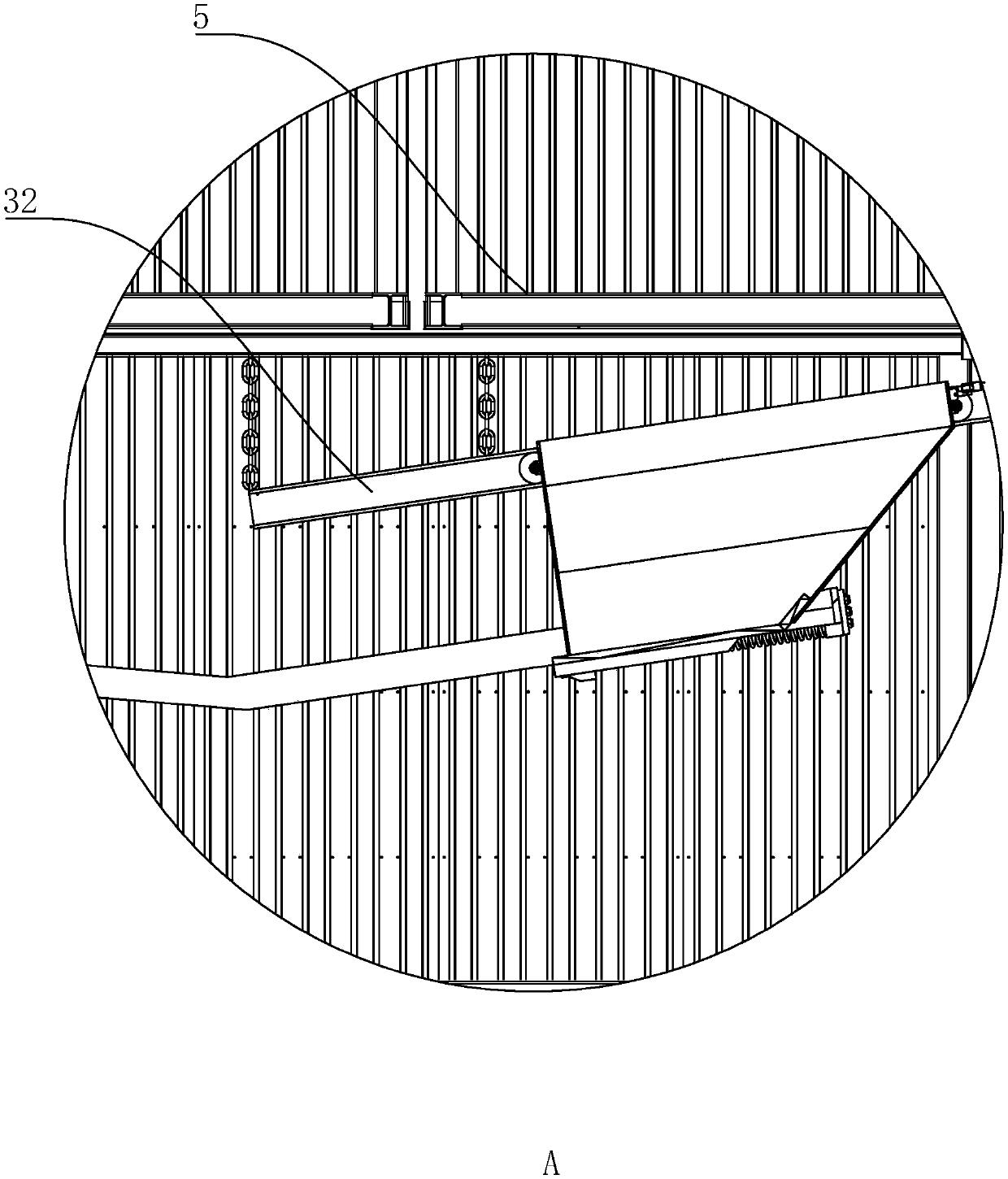

[0053] Such as figure 1 As shown, the container-type finished product silo 1 includes a container 11, and the containers 11 used in this embodiment have all passed the British BV certification and can be transported by sea. The bottom of container 11 is provided with several legs, and its bottom is hollowed out. The container 11 is provided with two single-layer silos 12, a double-layer transitional silo 13 and five double-layer silos 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com