Liquid extrusion mechanism

A squeeze mechanism, liquid technology, applied in the direction of transportation and packaging, loading/unloading, unsealing by removing items, etc., to achieve the effect of easy control and avoiding left and right tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

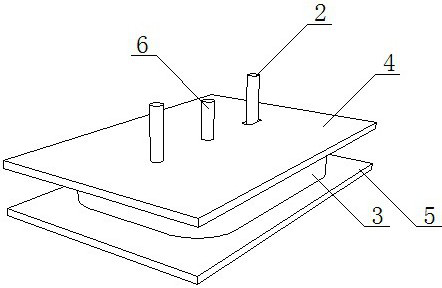

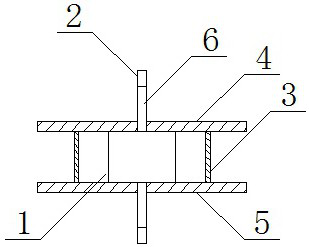

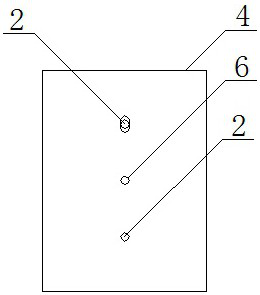

[0043] The liquid extrusion mechanism includes a turntable 1, a rotating shaft 2, an annular belt 3, an upper sealing plate 4, a lower sealing plate 5, and a liquid pipe 6. The turntable 1 is a square platform, and both ends of the turntable 1 are symmetrical arc structures. There are two turntables 1 and are arranged in parallel. The annular belt 3 is sleeved on the outside of the two turntables 1, and the turntable 1 tensions the endless belt 3. The width of the endless belt 3 is equal to the thickness of the turntable 1, so The upper sealing plate 4 is arranged on the two turntables 1, the lower sealing plate 5 is arranged on the bottom of the two turntables 1, the upper sealing plate 4 and the lower sealing plate 5 are provided with shaft holes, and the rotating shafts 2 are respectively Fixed at the top center and bottom center of the turntable 1, the rotating shaft 2 at the top center of the turntable 1 passes through the rotating shaft hole of the upper sealing plate 4, ...

Embodiment 2

[0045] The liquid extrusion mechanism includes a turntable 1, a rotating shaft 2, an annular belt 3, an upper sealing plate 4, a lower sealing plate 5, and a liquid pipe 6. The turntable 1 is a square platform, and both ends of the turntable 1 are symmetrical arc structures. There are two turntables 1 and are arranged in parallel. The annular belt 3 is sleeved on the outside of the two turntables 1, and the turntable 1 tensions the endless belt 3. The width of the endless belt 3 is equal to the thickness of the turntable 1, so The upper sealing plate 4 is arranged on the two turntables 1, the lower sealing plate 5 is arranged on the bottom of the two turntables 1, the upper sealing plate 4 and the lower sealing plate 5 are provided with shaft holes, and the rotating shafts 2 are respectively Fixed at the top center and bottom center of the turntable 1, the rotating shaft 2 at the top center of the turntable 1 passes through the rotating shaft hole of the upper sealing plate 4, ...

Embodiment 3

[0047] The liquid extrusion mechanism includes a turntable 1, a rotating shaft 2, an annular belt 3, an upper sealing plate 4, a lower sealing plate 5, and a liquid pipe 6. The turntable 1 is a square platform, and both ends of the turntable 1 are symmetrical arc structures. There are two turntables 1 and are arranged in parallel. The annular belt 3 is sleeved on the outside of the two turntables 1, and the turntable 1 tensions the endless belt 3. The width of the endless belt 3 is equal to the thickness of the turntable 1, so The upper sealing plate 4 is arranged on the two turntables 1, the lower sealing plate 5 is arranged on the bottom of the two turntables 1, the upper sealing plate 4 and the lower sealing plate 5 are provided with shaft holes, and the rotating shafts 2 are respectively Fixed at the top center and bottom center of the turntable 1, the rotating shaft 2 at the top center of the turntable 1 passes through the rotating shaft hole of the upper sealing plate 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com