Photocatalytic selective metal dissolving agent and dissolving method

A photocatalyst and selective technology, applied in the field of photocatalysis, can solve the problems of complicated preparation steps of carbon tube composite films, and achieve the effects of low cost, convenient operation and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

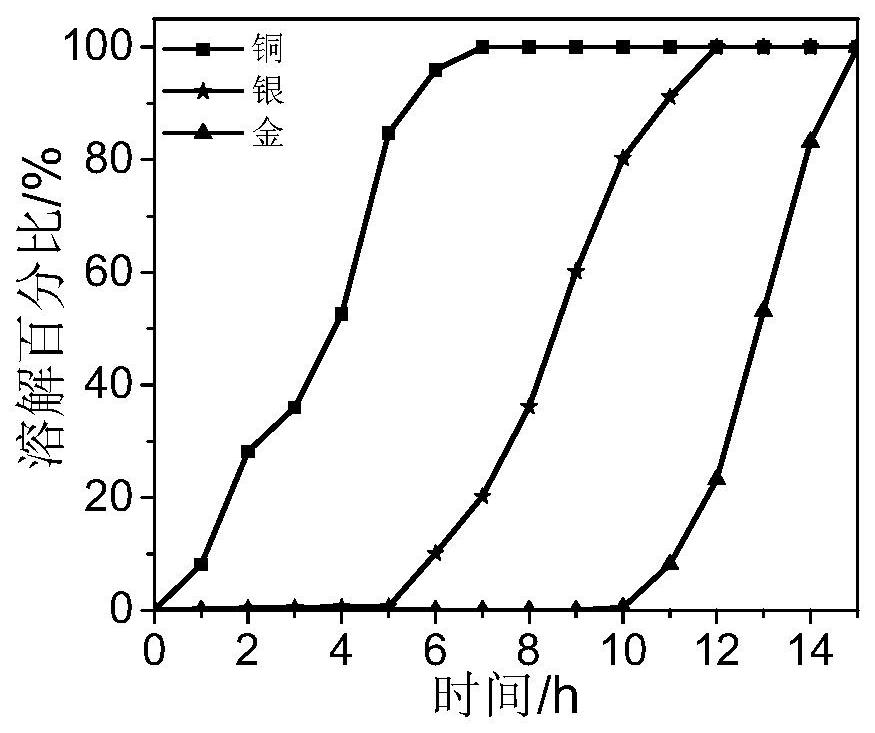

[0029] Disperse 500mg of materials containing the same amount of copper, silver, and gold into 50ml of acrylonitrile solution, then add 50mg of commercially available mixed-phase titanium dioxide catalyst, irradiate with ultraviolet light in air for 4 hours, the metal dissolution rate is 100%, and the dissolution order is copper, silver ,gold.

[0030] figure 1 It is the dissolution ratio curve diagram of the three metal selective dissolution reactions. From the ICP test data, it can be clearly seen that the metal dissolution sequence in the liquid is copper, silver, gold, and the proportion of the three metals is increasing continuously (take a small amount of solution and evaporate the solvent Add an equal amount of solvent to dilute with water for detection).

Embodiment 2

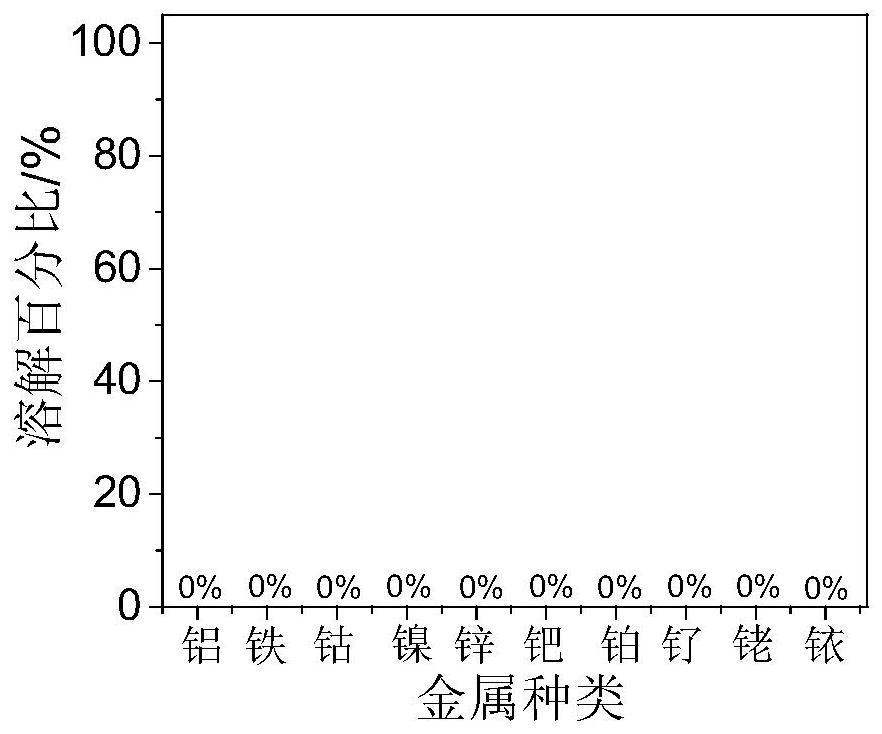

[0032] Disperse 500mg of materials containing equivalent amounts of aluminum, iron, cobalt, nickel, zinc, palladium, platinum, ruthenium, rhodium, and iridium into 500ml of acrylonitrile solution, then add 50mg of commercial mixed-phase titanium dioxide catalyst, and irradiate with ultraviolet light for 4h in the air , the metal dissolution rate is 0%.

[0033] figure 2 It is the dissolution ratio curve diagram of the selective dissolution reaction of various metals. From the ICP test data, it can also be clearly seen that there is no metal dissolution in the liquid (take a small amount of solution to evaporate the solvent and add water with an equal amount of solvent to dilute it for detection), which shows that The method is exceptionally selective for the metals copper, silver and gold.

Embodiment 3

[0035] Disperse 50mg of materials containing 1% copper, 1% silver and 1% gold into 20ml acrylonitrile solution, then add 50mg commercial mixed-phase titanium dioxide catalyst, irradiate with ultraviolet light in air for 4h, the dissolution rate of metal is 100%.

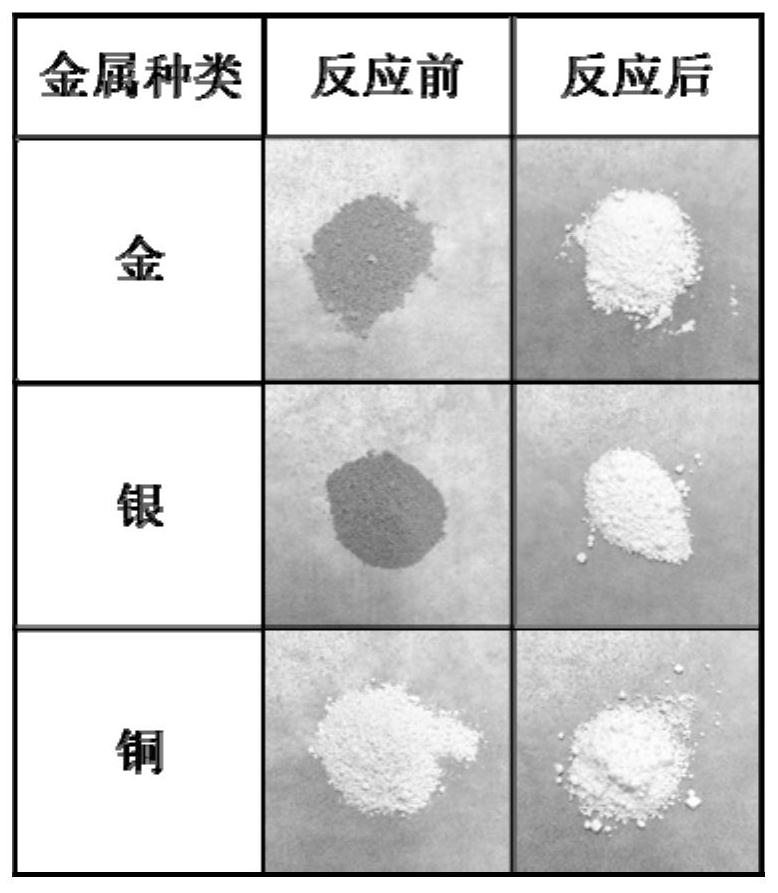

[0036] From image 3 It can be seen that the samples were purple (gold), red (silver) and green (copper) before dissolution, and all the samples turned white after the dissolution reaction.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap