Non-condensable gas separation system and method based on ammonia system

A gas separation and condensation technology, applied in refrigeration components, refrigerators, lighting and heating equipment, etc., can solve problems such as increased power consumption of compressors, explosion, and reduction of cooling capacity and cooling coefficient of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

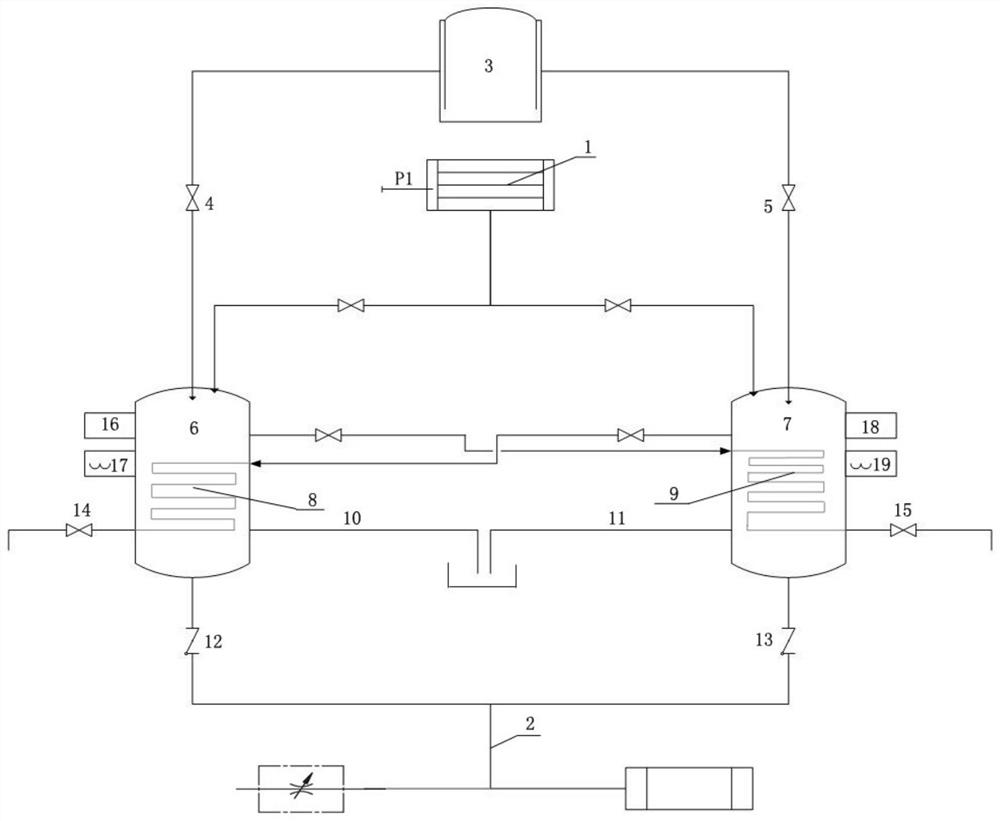

[0115] Below, a kind of non-condensable gas separation system and method based on the ammonia system of the present invention will be further specifically described according to the accompanying drawings and specific embodiments.

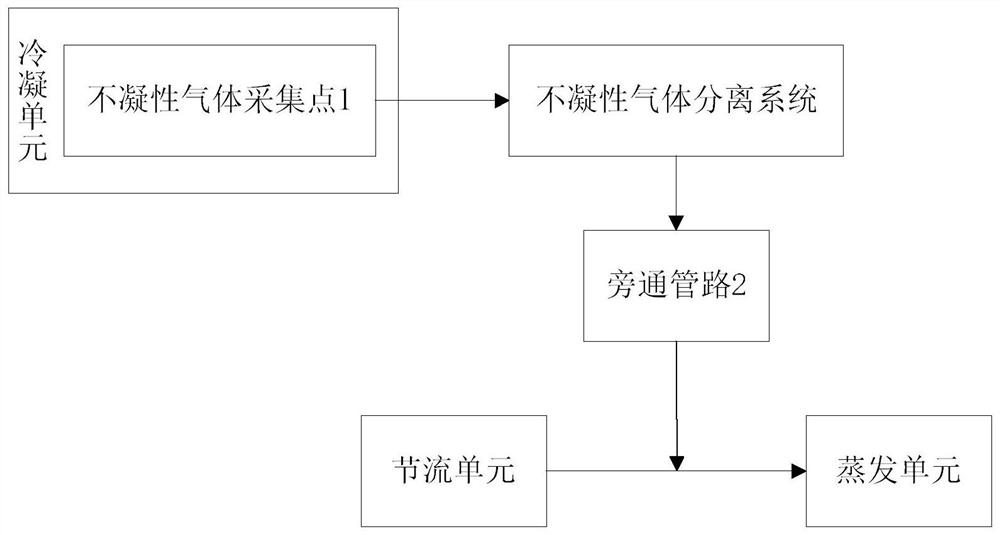

[0116] Such as figure 1 A non-condensable gas separation system based on the ammonia system is shown. The non-condensable gas separation treatment is set for the condensation unit, throttling unit and evaporation unit of the thermal cycle of the ammonia system. Condensable gas collection point (1),

[0117] A bypass pipeline (2) is arranged in parallel on the pipeline leading from the throttling unit to the evaporation unit;

[0118] A non-condensable gas separation system is arranged between the gas outlet of the non-condensable gas collection point (1) and the bypass pipeline (2);

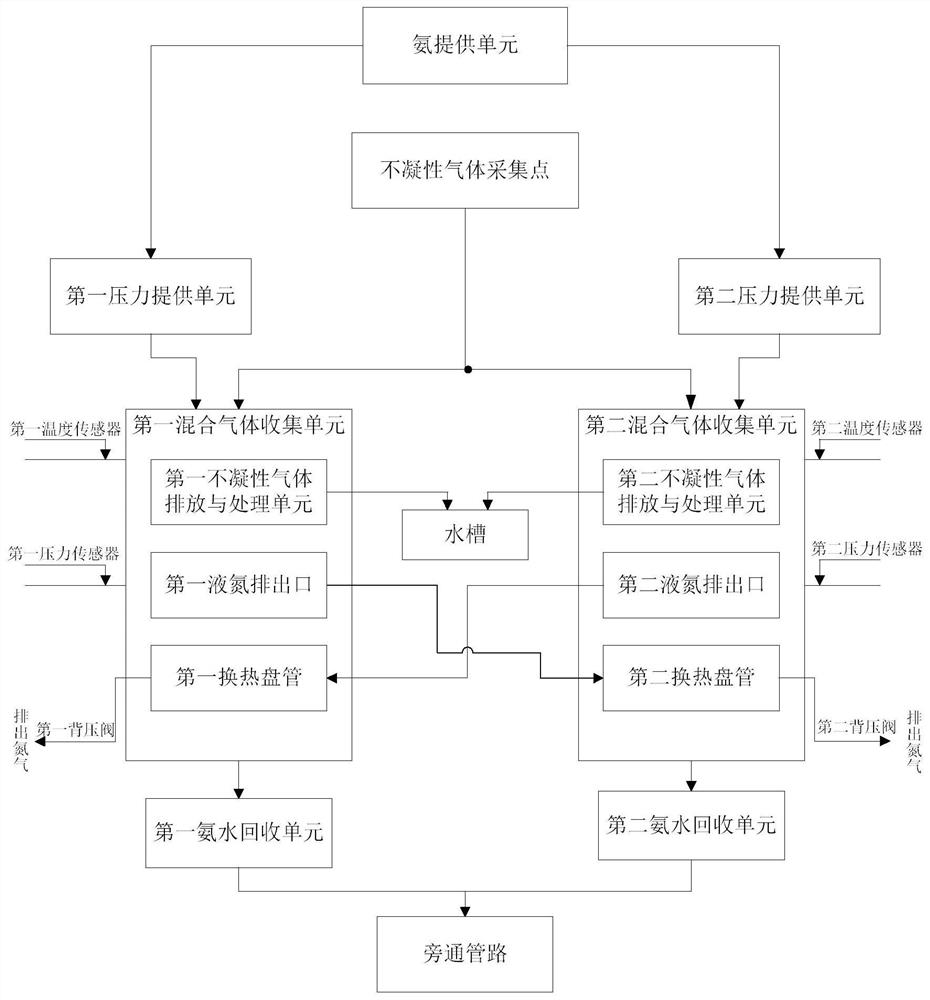

[0119] In the non-condensable gas separation system, a mixed gas collection unit, a nitrogen pressurization unit, a non-condensable gas discharge and treatment unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com