A small aviation piston engine crankshaft docking measurement device

A piston engine and measuring device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of repeated calibration process, cumbersome measurement process, low efficiency, etc., to eliminate measurement system deviation, eliminate system drift, and improve control quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

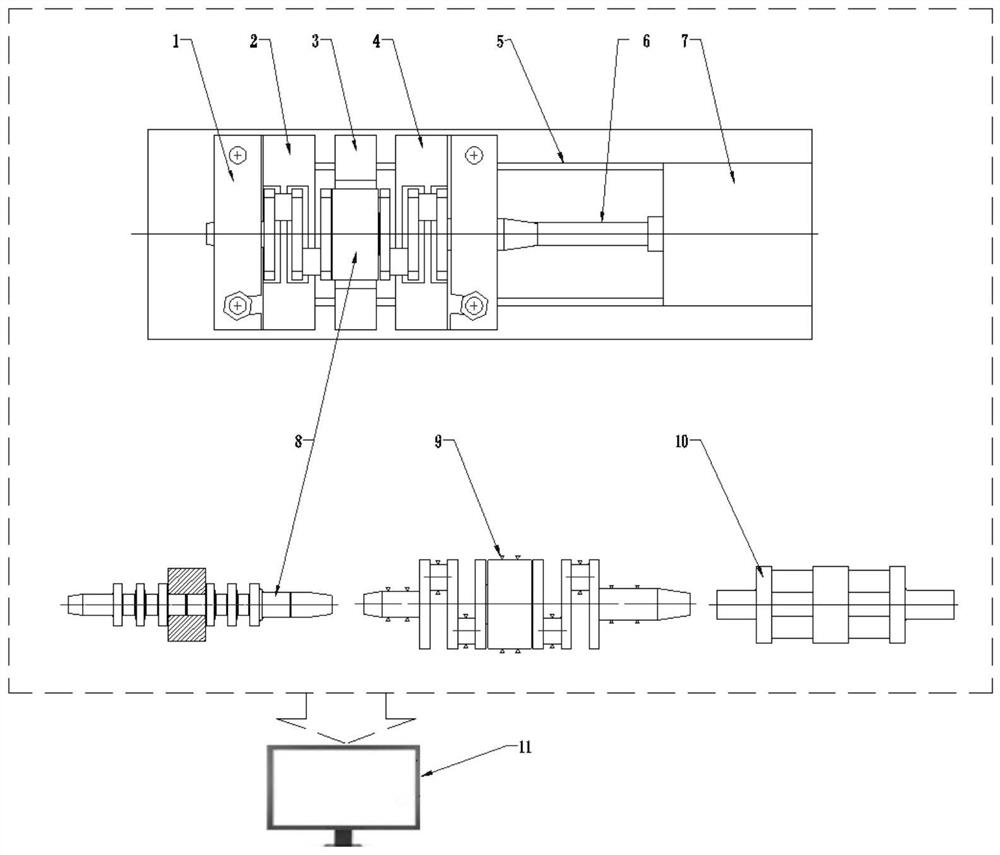

[0026] This embodiment is a small aircraft piston engine crankshaft docking measurement device.

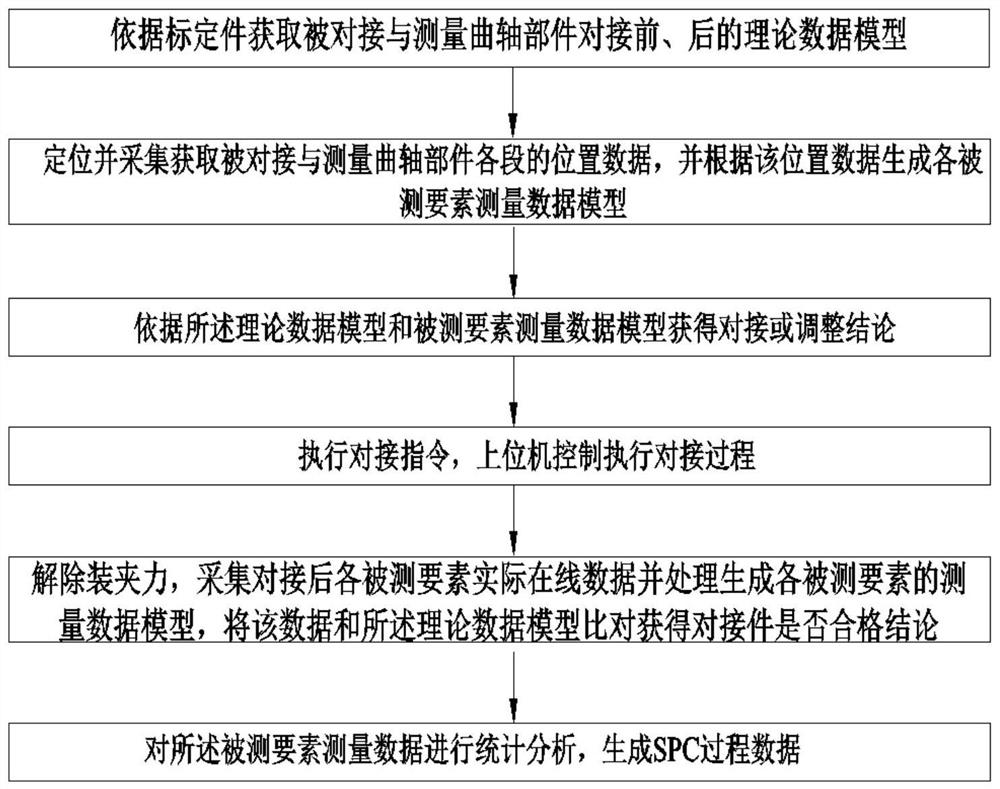

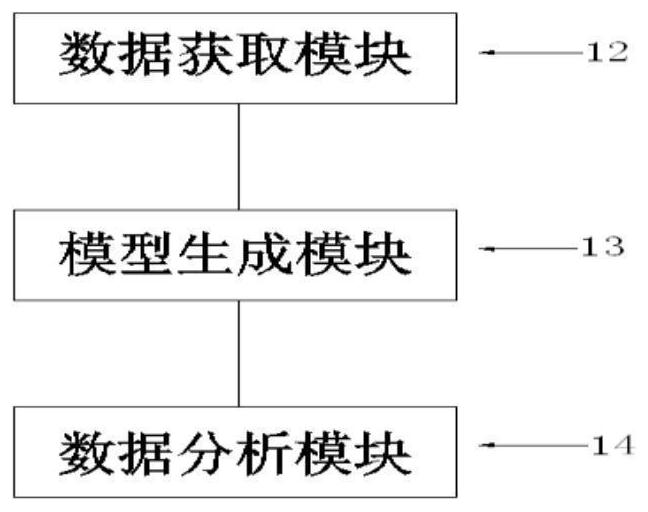

[0027] see Figure 1 to Figure 4 , The small aero-piston engine crankshaft docking measurement device in this embodiment consists of a positioning docking tool 1, a left segment locator 2, a middle segment locator 3, a right segment locator 4, a sliding guide 5, a lead screw 6, a drive motor 7, and crankshaft components 8. The measuring head 9, the calibration part 10, the host computer 11, the data acquisition module 12, the model generation module 13, and the data analysis module 14 are composed; among them, the positioning and docking tool 1 is used as the actuator, which is divided into the left section locator 2, the middle section positioning The locator 3 and the right segment locator 4 are mounted on the locating and docking tool 1 by the butt measuring crankshaft part 8 . The middle section locator 3 and the right section locator 4 are installed on two parallel sliding g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com