Efficient treatment equipment for textile wastewater

A technology for treating equipment and textile wastewater, which is applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., and can solve the problems of low desorption efficiency, large water volume and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

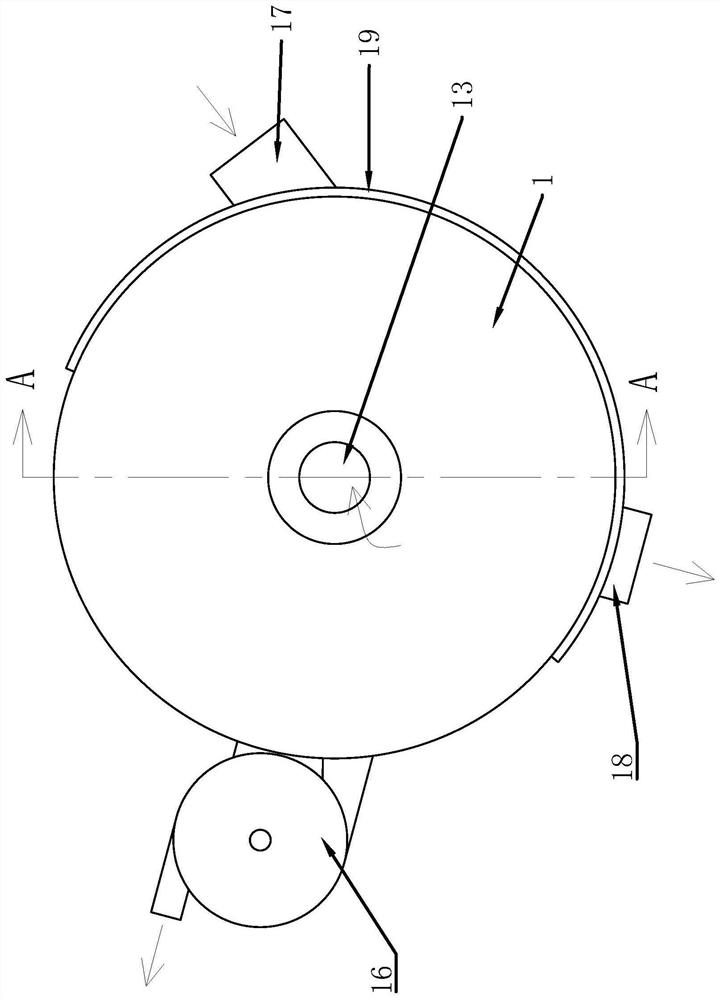

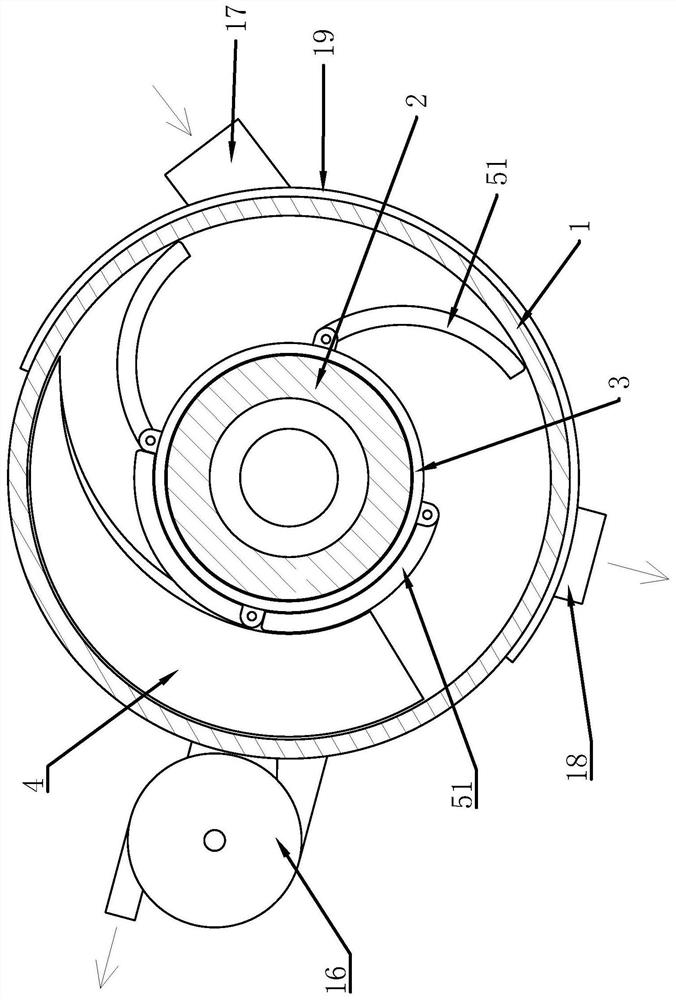

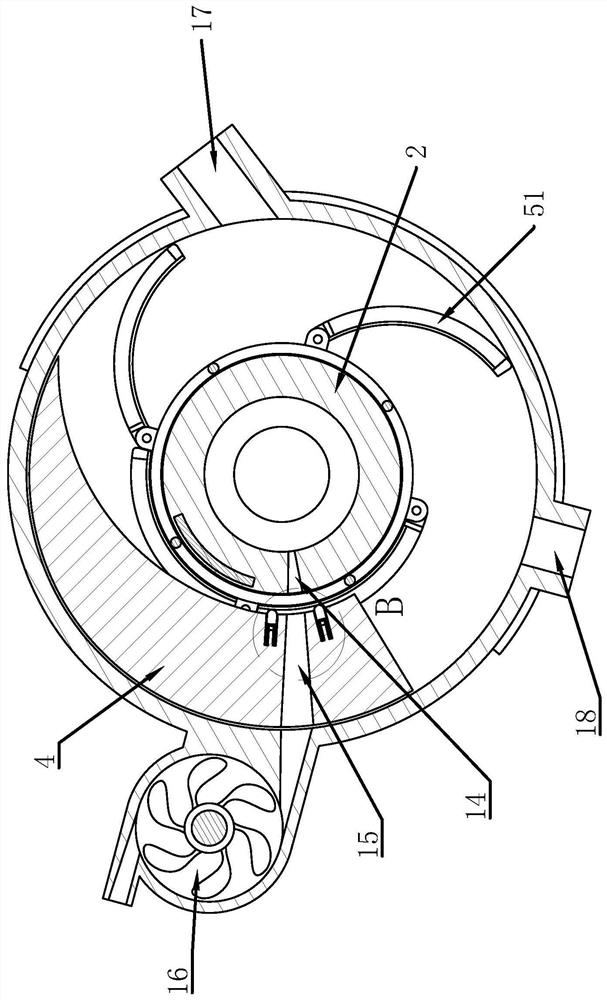

[0031] Such as Figure 1 to Figure 9 As shown, it includes a cylindrical housing 1, a positioning cylinder 2 fixedly connected to the housing 1, a swivel 3 rotatably connected to the outside of the positioning cylinder 2, and a limit guide block 4 fixed on the inner wall of the housing 1. The housing 1 and the positioning cylinder 2 form an annular water storage chamber 11, the swivel 3 is driven by a geared motor 12, and a number of arc-shaped installation frames 51 are hinged outside the swivel 3, and a filter screen 52 is installed in the middle of the installation frame 51 , the hinge points of each mounting frame 51 and the swivel 3 are evenly distributed circumferentially on the outer wall surface of the swivel 3, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com