Multi-head saw cutting device for pipes

A sawing device and pipe technology, which is applied in sawing machine devices, metal sawing equipment, metal processing equipment, etc., can solve the problems that the pipe conveying speed cannot be too fast, the short pipe cannot be cut, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below through specific examples.

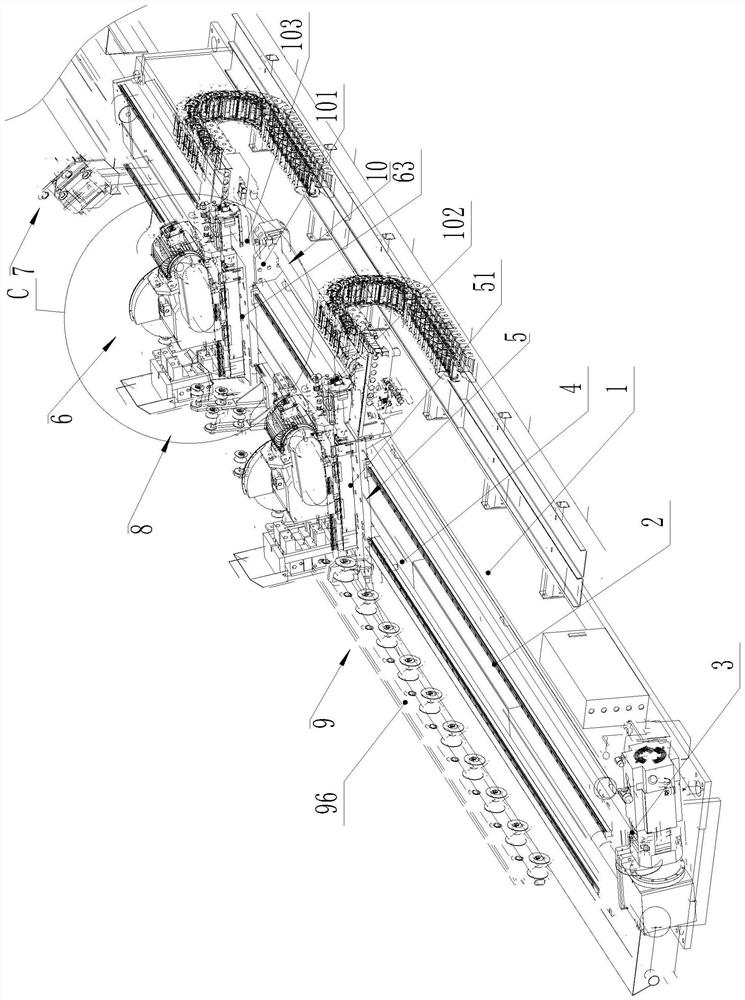

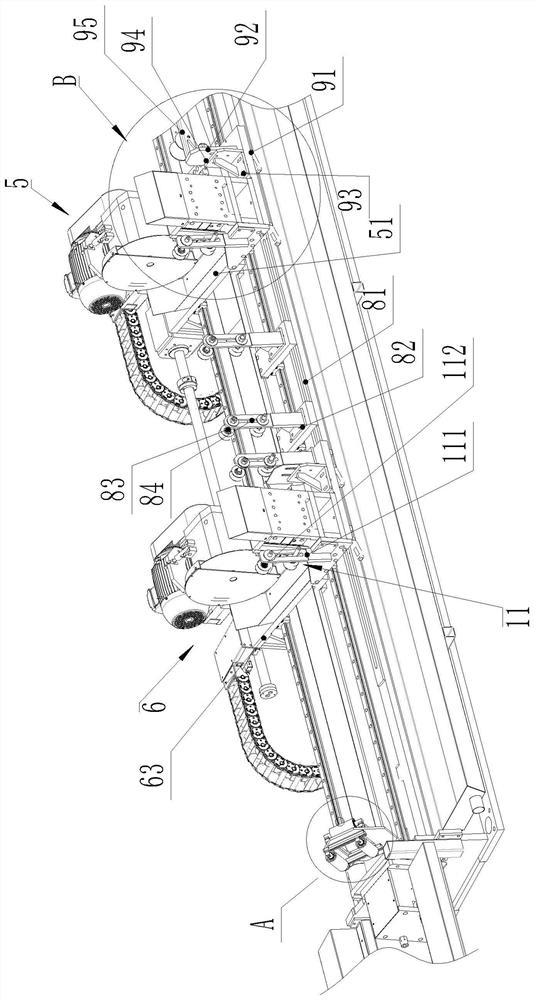

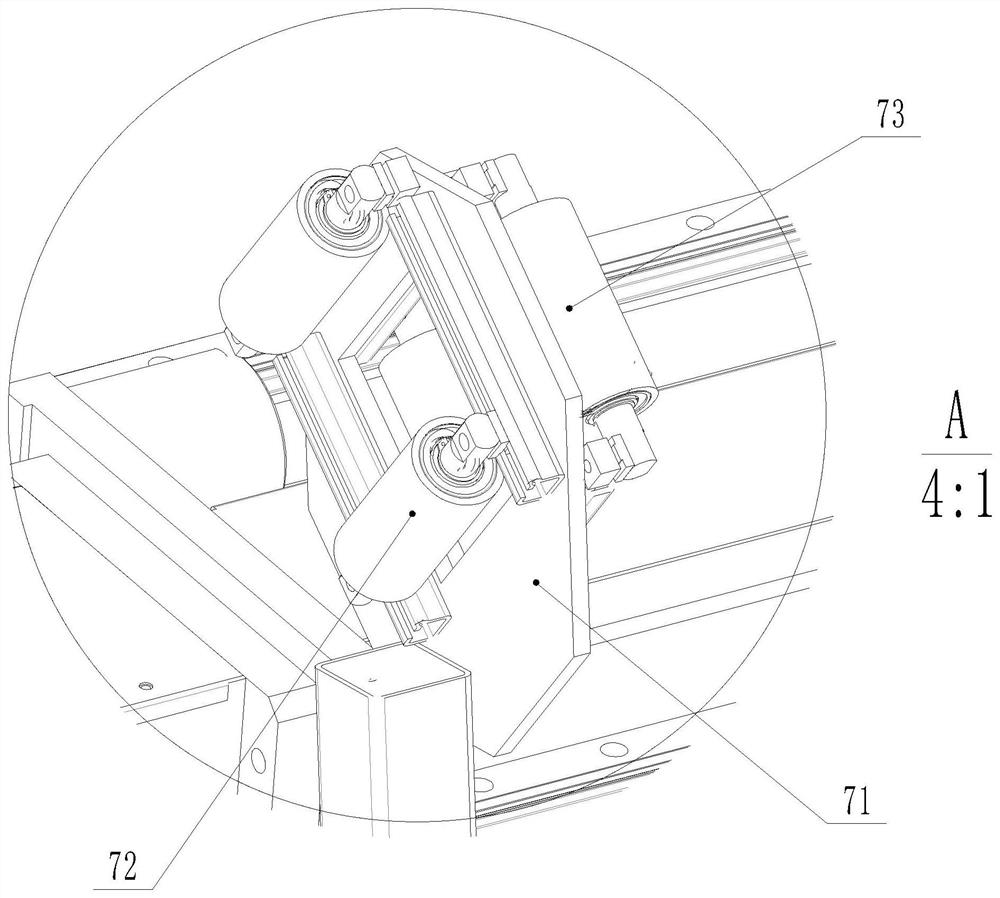

[0031] Such as Figure 1 to Figure 5 As shown, a multi-head sawing device for pipes includes a horizontal machine base 1, on which a guide rail 2 is arranged, and the multi-head sawing device also includes at least two sawing heads connected in series, and each saw The bases of the cutting heads are directly or indirectly slidably installed on the guide rail 2, and a linkage mechanism 10 is installed between adjacent bases.

[0032] Wherein, the way that the base is directly slidably installed on the guide rail 2 is that each sawing head is installed on the guide rail 2 through a slider that cooperates with the guide rail 2, so as to realize sliding. At this time, the linkage mechanism 10 can be installed on the adjacent base The upper linkage lever realizes linkage.

[0033] The specific way that the base is indirectly slidably installed on the guide rail 2 is as follows: a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com