A pulse power energy transmission circuit in reciprocating wire EDM wire cutting

A technology of pulse power supply and electric spark wire, which is applied in the field of pulse power supply energy transmission circuit, can solve the problems of large material removal, waist drum, waist drum degree error, etc., achieve discharge probability balance, reduce discharge energy, and reduce waist drum degree error Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

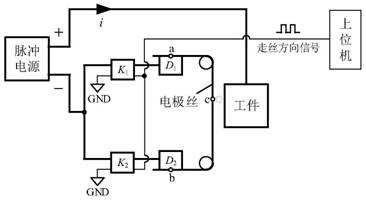

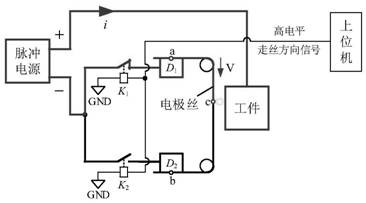

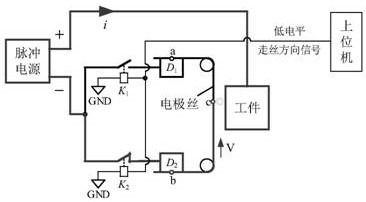

[0025] In order to make the purpose, technical solutions and advantages of the present application more clearly understood, the present application will be described in further detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present application, but not to limit the present application.

[0026] The invention is a pulse power supply energy transmission circuit in the reciprocating wire EDM process. By connecting the upper and lower conductive blocks of the machine tool to the circuit alternately, the equivalent resistance of the electrode wire at various discharge points is increased, and the various parts of the workpiece surface are reduced. The discharge energy of the discharge point, as well as the energy difference of different discharge points, realizes the energy balance of the discharge points on the surface of the workpiece during discharge, so ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com