Laser drilling machine capable of reducing eye fatigue of workers and avoiding taper

A laser drilling and staffing technology, applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as external environmental pollution, eye discomfort of staff, laser damage, etc., to avoid taper and reduce eye fatigue Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

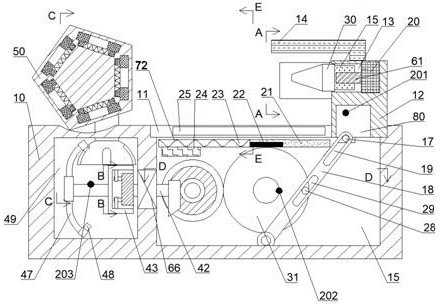

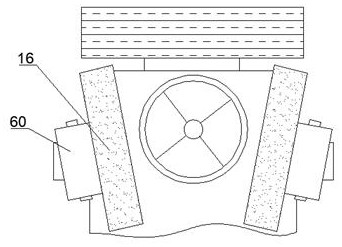

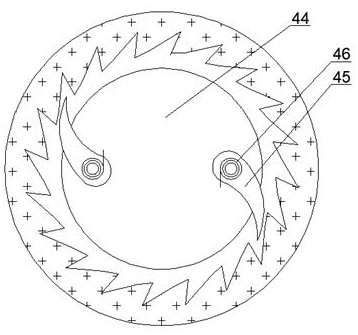

[0021] Combine below Figure 1-8 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0022] combined with Figure 1-8 The laser drilling machine that reduces eye fatigue of workers and avoids taper includes a fuselage 10 and a first transmission chamber 15 that opens upward in the fuselage 10, and the first transmission chamber 15 can be The rotating wheel 31 is provided with a first round pin 28 fixed at the front end of the rotating wheel 31, and a rocker 18 is hinged at the bottom end of the first transmission chamber 15, and a rocker 18 is provided in the rocker 18 to penetrate forward and backward. The first round groove 29 and the second round groove 19 that cooperate with the first round pin 28 to drive, the rocker 18 extends upwards into the first moving cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com