Spliced wall decoration pre-coated steel plate

A technology for pre-coated steel plates and splicing walls, applied in the direction of coatings, building components, layered products, etc., can solve the problems of smooth surface, monotonous visual effect, side damage, inconvenient construction, etc., and achieve a rich appearance. , Improve the defect of smooth surface, save the effect of installation labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

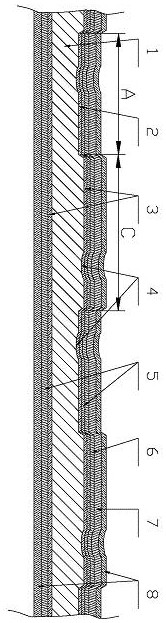

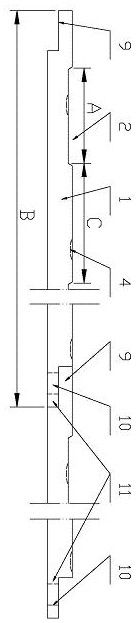

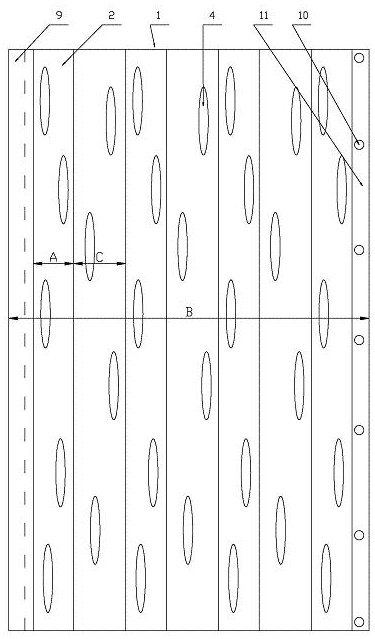

[0023] exist figure 1 and figure 2 In the spliced wall decoration pre-painted steel plate shown, the rectangular steel plate body 1 is a carbon structural steel plate, and grooves 2 are arranged at intervals on the upper surface of the steel plate body 1, see image 3 The length of the groove 2 is parallel to the length of the steel plate body 1 and the length of the groove 2 is equal to the length of the steel plate body 1. The ratio A:B of the width A of the groove 2 and the width B of the steel plate body 1 is 1: 6~1:15, the ratio A:C of the width A of the groove 2 to the distance C between two adjacent grooves 2 is 0.3:1~1:1, and there is an overlapping bottom edge on one side of the steel plate body 1 11. The side opposite to this side is provided with a lap top edge 9, and the lap bottom edge 11 can be plugged into the lower part of the lap top edge 9, and the sum of the thickness of the lap bottom edge 11 and the lap top edge 9 is equal to the steel plate body The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com