Push plate and rubber bottom plate follow-up unloading device and transport vehicle

A technology of unloading device and push plate, which is applied in the field of transport vehicles, which can solve the problems of residual substance adsorption, incomplete unloading, and inconvenient cleaning of the compartment, and achieve the effect of clean and tidy compartment, safe and fast unloading, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

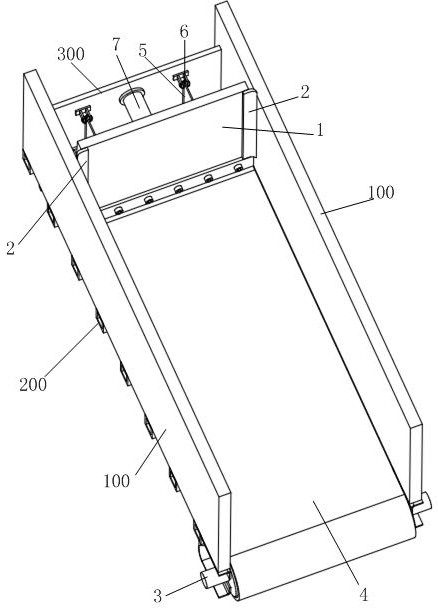

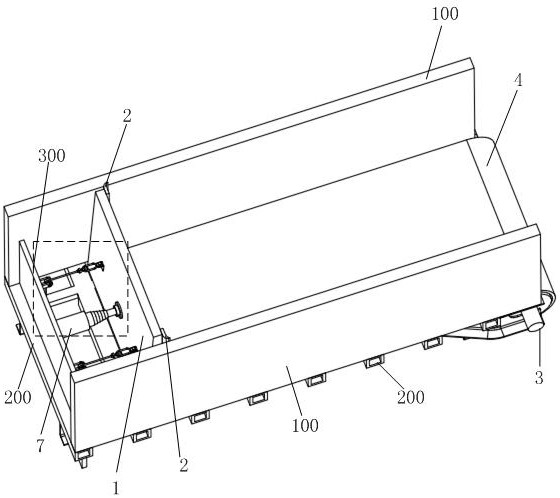

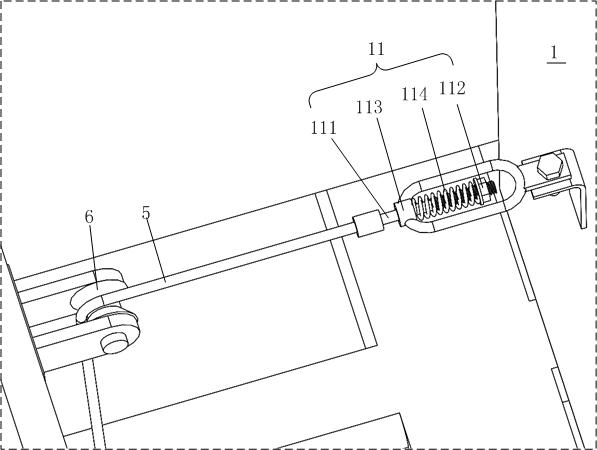

[0025] Example 1, such as Figure 1-4 The shown one kind of unloading device with push plate and rubber bottom plate is characterized in that it includes a push plate 1, and the two ends of the push plate 1 are respectively fixed with elastic scrapers that can abut against the inner sides of the two side plates 100 of the carriage 2. A rear axle 3 is pivoted on the frame 200 at the rear end of the compartment, the lower end of the push plate 1 is fixed to the front end of the rubber base plate 4, and the rear end of the rubber base plate 4 can bypass the rear axle 3 and then be fixed to two steel wire ropes 5 The other end of the two steel wire ropes 5 is affixed to the push plate 1 through the guide wheel 6; the front baffle 300 is affixed to the vehicle frame 200 and the two side panels 100 of the carriage, and the cylinder body of an oil cylinder 7 It is connected with the front baffle 300 , and the cylinder rod of the oil cylinder 7 is connected with the push plate 1 . Th...

Embodiment 2

[0027] Example 2, such as Figure 5 The shown one kind of unloading device with push plate and rubber base plate moving, comprises push plate 1, and the two ends of described push plate 1 are respectively fixed with the elastic scraper 2 that can abut against the inside of two side plates 100 of the compartment; The rear axle 3 is pivoted on the vehicle frame 200 at the end, and the front axle 8 is pivoted on the vehicle frame 200 at the front end of the compartment. Two chains 9 are wound around the front axle 8 and the rear axle 3 through sprockets. The lower end is affixed to the front end of the rubber base plate 4 and is affixed to the two pairs of the chains 9. The rear end of the rubber base plate 4 can bypass the rear axle 3 and be affixed to the two pairs of the chains 9. The rear axle 3 is hydraulically Motor 10 drives. The width of the push plate 1 is equal to or slightly smaller than the distance between the two side panels 100 of the carriage, and the width of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com