Automatic lens identifying and clamping device

An automatic identification and lens technology, applied in the field of optical communication, can solve problems such as low clamping efficiency, low clamping accuracy, and long time consumption, and achieve the effect of improving processing efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0024] The present invention provides an automatic lens identification and clamping device aiming at the problems of low efficiency, long time consumption and easily affected product quality in the existing lens clamping and coupling mode.

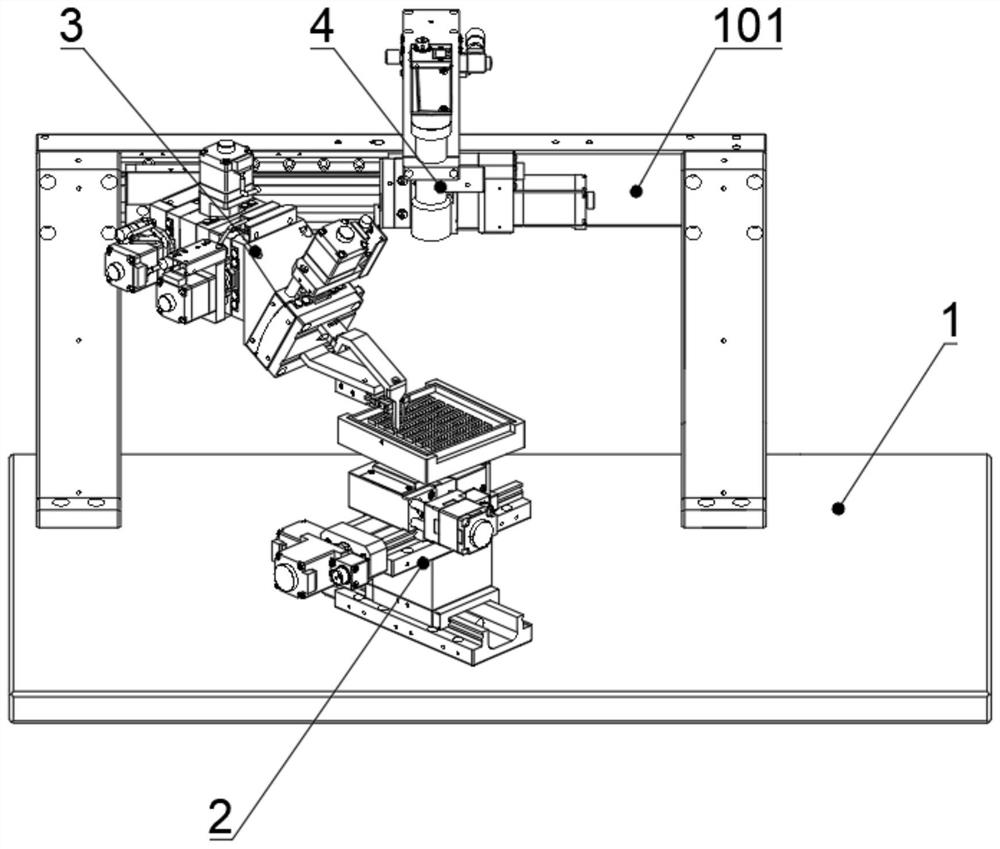

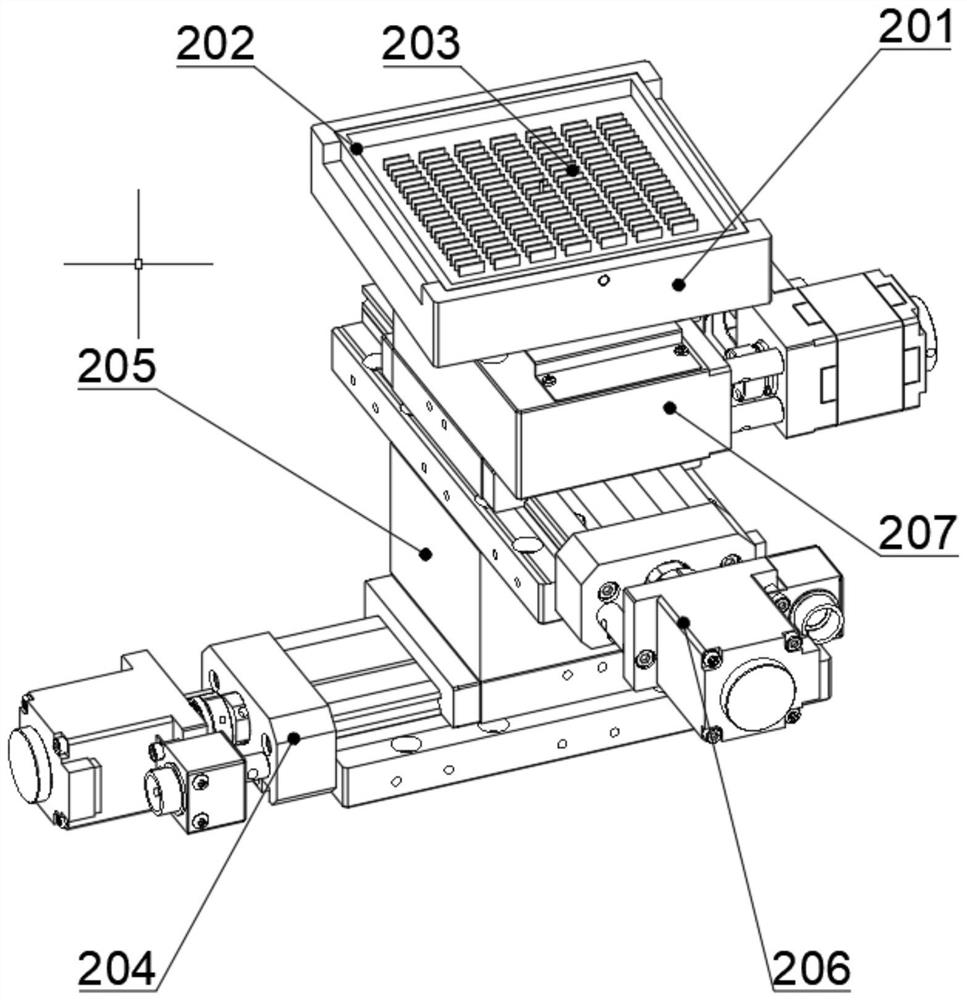

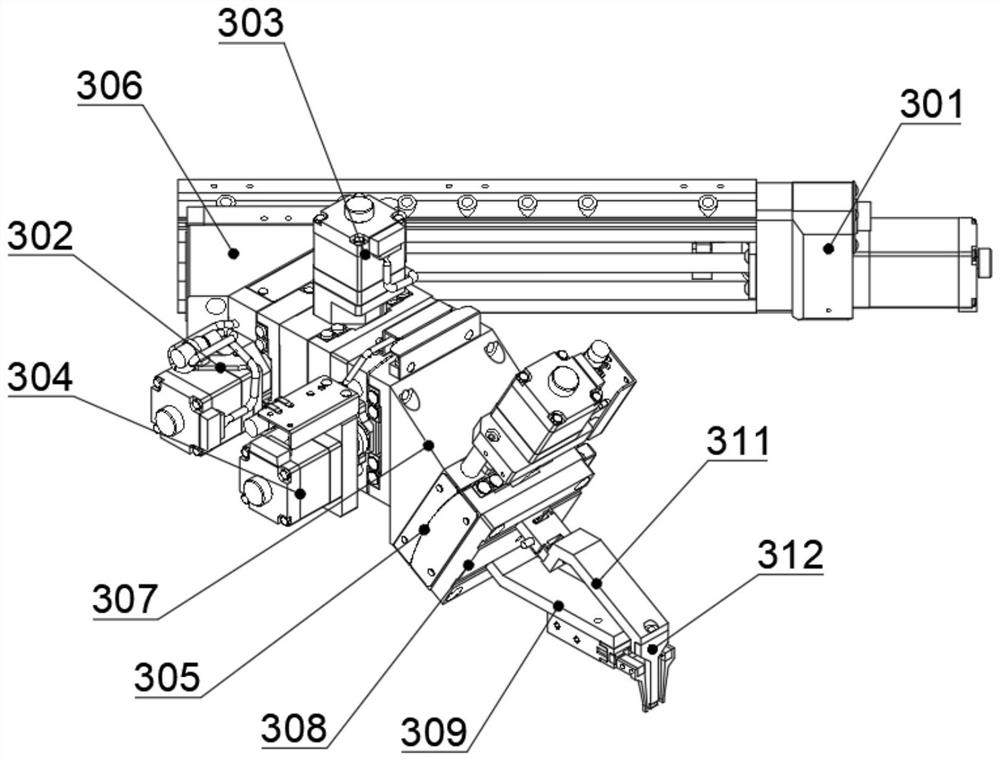

[0025] Such as Figure 1 to Figure 5 As shown, the embodiment of the present invention provides an automatic lens identification and clamping device, including: a device base plate 1, the device base plate 1 is arranged on a plane, and a beam 101 is arranged on the device base plate 1; a tray unit 2, The tray unit 2 is provided with a tray moving mechanism and a tray mounting seat 201, and the tray installation seat 201 is arranged on the bottom plate 1 of the device through the tray moving mechanism, and the tray mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com