Ultraviolet sterilizer for tap water treatment

A technology of ultraviolet rays and sterilizers, which is applied in water/sewage treatment, light water/sewage treatment, water/sewage treatment equipment, etc. It can solve the problems of affecting the sterilization speed of water flow, reducing water flow, and occupying the space of sterilizers. The effects of stable cleaning, reduced vibration amplitude, and faster cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

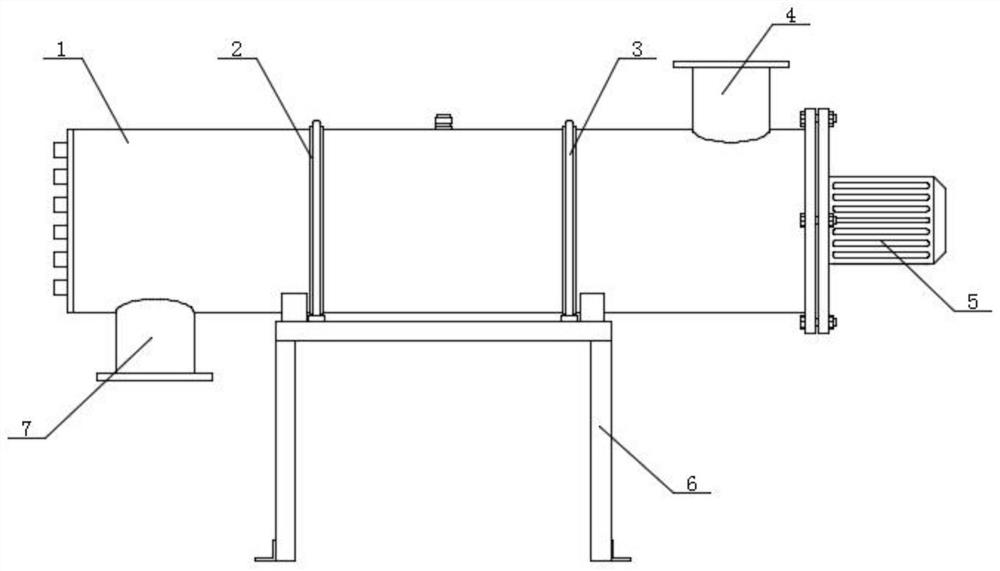

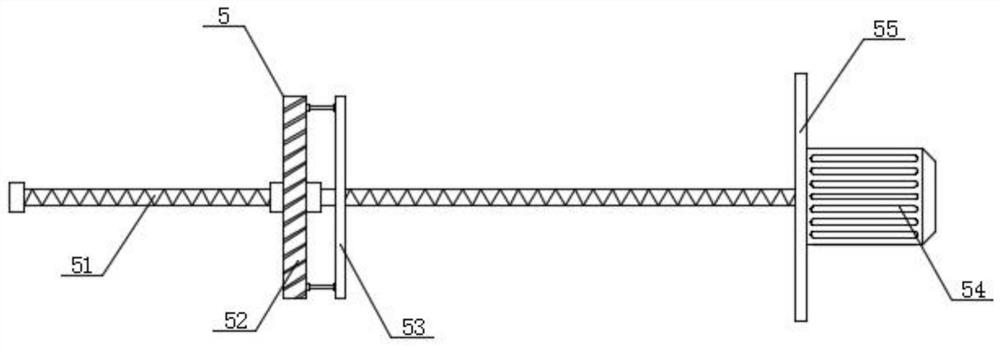

[0023] Such as Figure 1-2 As shown, an ultraviolet sterilizer for tap water treatment includes a support frame 6, an outer tube 1 is fixed on the upper end of the support frame 6, a buffer pad 2 is fixed on the upper end of the outer tube 1, and a fixed belt 3 is fixed on the upper end of the buffer pad 2, The right side of the fixing belt 3 is fixed with an outlet pipe 4 at the upper end of the outer pipe 1, the left side of the support frame 6 is fixed with a water inlet pipe 7 at the lower end of the outer pipe 1, and the right end of the outer pipe 1 is fixed with a cleaning device 5 by bolts , cleaning device 5 comprises power motor 54, and the left end of power motor 54 is fixed with fixed flange 55, and the left end of fixed flange 55 is fixed with screw rod 51, and the surface of screw rod 51 is connected with cleaning plate 52 by screw thread rotation, and the right end of cleaning plate 52 A push plate 53 is fixed.

[0024] Connect the water inlet pipe 7 and the wa...

Embodiment 2

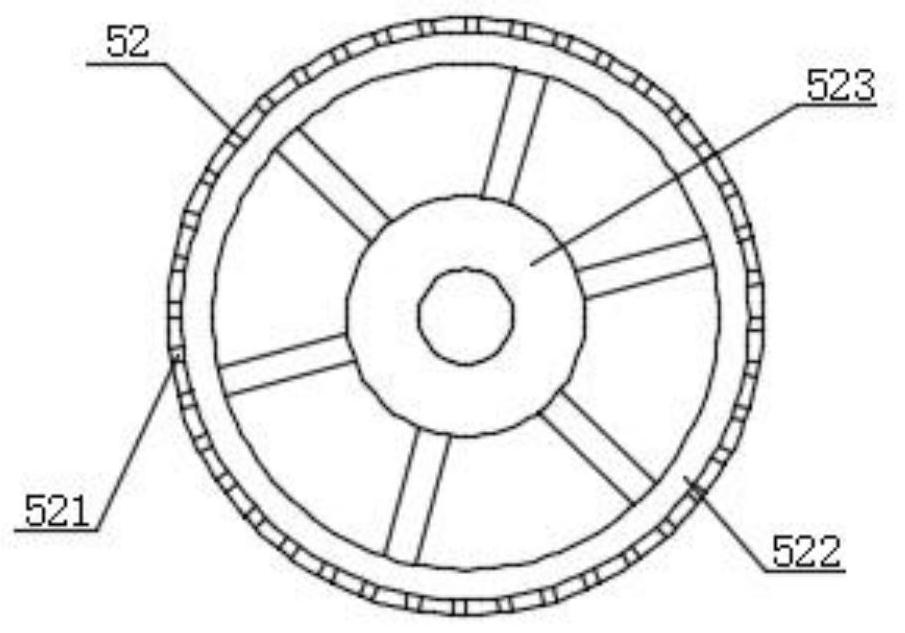

[0026] Such as Figure 1-3 As shown, an ultraviolet sterilizer for tap water treatment includes a support frame 6, an outer tube 1 is fixed on the upper end of the support frame 6, a buffer pad 2 is fixed on the upper end of the outer tube 1, and a fixed belt 3 is fixed on the upper end of the buffer pad 2, The right side of the fixing belt 3 is fixed with an outlet pipe 4 at the upper end of the outer pipe 1, the left side of the support frame 6 is fixed with a water inlet pipe 7 at the lower end of the outer pipe 1, and the right end of the outer pipe 1 is fixed with a cleaning device 5 by bolts , The cleaning plate 52 includes a rubbing tooth 521, a drive ring 522 is fixed in the middle of the scratch tooth 521, and a connecting block 523 is fixed in the middle of the drive ring 522 through a connecting rod.

[0027] The inclined setting of the scraping teeth and the transmission ring 522 can increase the contact angle with the inner surface of the outer tube 1 and speed up...

Embodiment 3

[0029] Such as Figure 1-4 As shown, an ultraviolet sterilizer for tap water treatment includes a support frame 6, an outer tube 1 is fixed on the upper end of the support frame 6, a buffer pad 2 is fixed on the upper end of the outer tube 1, and a fixed belt 3 is fixed on the upper end of the buffer pad 2, The right side of the fixing belt 3 is fixed with an outlet pipe 4 at the upper end of the outer pipe 1, the left side of the support frame 6 is fixed with a water inlet pipe 7 at the lower end of the outer pipe 1, and the right end of the outer pipe 1 is fixed with a cleaning device 5 by bolts , The buffer pad 2 includes a pad body 21 , and a groove 22 is fixed on the surface of the pad body 21 .

[0030] The cushion body 21 is attached to the surface of the outer tube 1. Since there is water flow inside the outer tube 1, the moving water flow will drive the outer tube 1 to vibrate, and the vibration of the outer tube 1 relative to the fixed belt 3 will cause surface wear,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com