Protein/Polysaccharide Composite Nanofilm and Its Application to Prevent Cracks in Conductive Coatings

A nano-film and polysaccharide composite technology, which is applied in coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems that are not suitable for industrial production, time-consuming dopamine modification process, expensive dopamine, etc., to expand options properties, increased roughness and surface area, and improved adhesion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

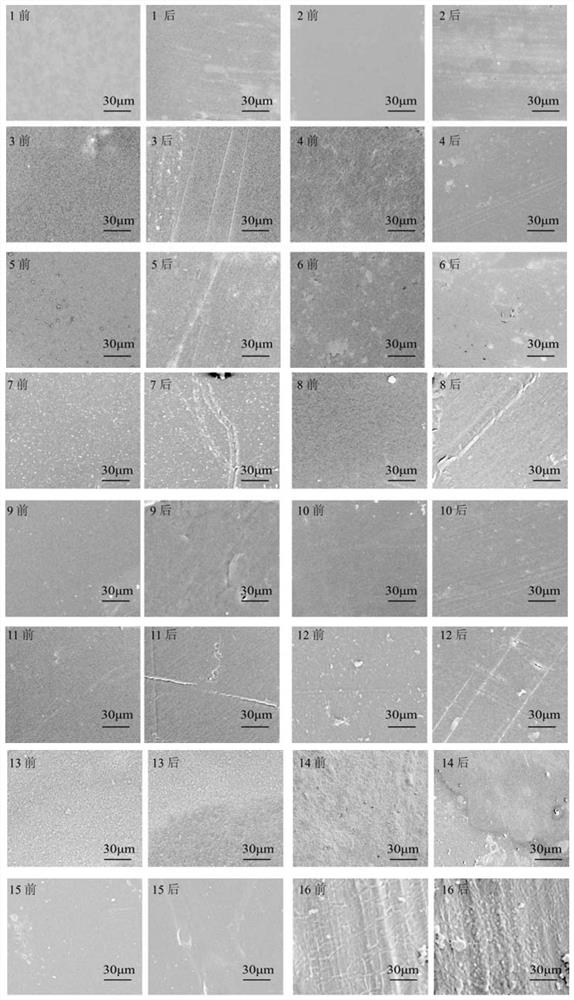

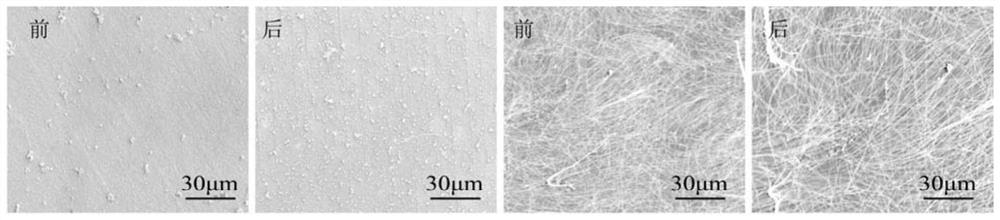

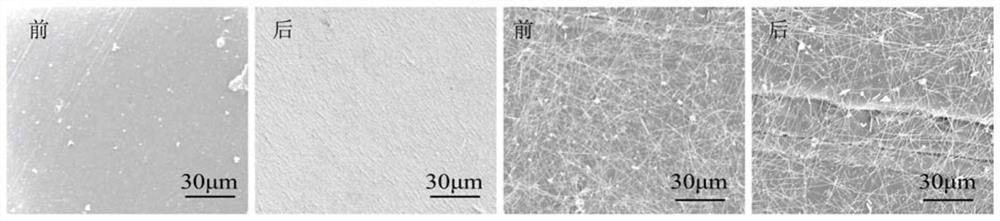

Embodiment 1

[0054] 0.1433g tris (2-carboxyethyl) phosphonate is added in 10mL 10mmol / L pH value is in the 4-hydroxyethylpiperazine ethanesulfonic acid buffer solution of 7.4, is mixed with 50mmol / L tris (2-carboxyethyl) ) 4-hydroxyethylpiperazine ethanesulfonic acid buffer solution of phosphonate (pH=1.80), and then adjust its pH value to 6.0 with NaOH, which is recorded as solution 1; 5mL of 5mg / mL lysozyme aqueous solution and 5mL of 1mg / mL Mix the aqueous solution of sodium alginate and record it as solution 2; mix solution 1 and solution 2 evenly, and let stand for 60 minutes at room temperature to form a nano-film at the solid-liquid interface; then immerse the nano-film in a 2% mass concentration In an aqueous solution of glutaraldehyde, cross-linking was performed at room temperature for 2 hours to obtain a lysozyme / sodium alginate composite nanofilm.

Embodiment 2

[0056] In this example, the 1 mg / mL sodium alginate aqueous solution in Example 1 was replaced with an equal volume of 1 mg / mL chitosan aqueous solution, and other steps were the same as in Example 1 to obtain a lysozyme / chitosan composite nanofilm.

Embodiment 3

[0058] In this example, the 1 mg / mL sodium alginate aqueous solution in Example 1 was replaced with an equal volume of 1 mg / mL sodium carboxymethyl cellulose aqueous solution, and other steps were the same as in Example 1 to obtain lysozyme / sodium carboxymethyl cellulose composite nanofilm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com