Manufacturing method of water injection packer, water injection packer easy to release, and construction method

A manufacturing method and packer technology, which is applied in the directions of sealing/packing, earthwork drilling, mining fluids, etc., and can solve the problems of complex unsealing mechanism, water scaling and easy jamming of water injection packers, etc. , to achieve the effect of avoiding poor thread connection performance, avoiding poor tensile performance, and improving the success rate of unsealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

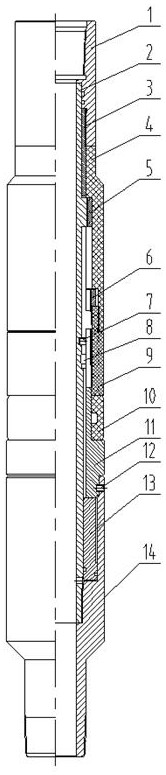

[0040] The upper body of the unblocking claw 3 is a cylindrical body, the lower body is a claw piece, an unlocking boss is provided at the bottom of the claw piece, and an unsealing shear nail assembly hole and an unlocking button are provided in the claw piece below the unlocking boss. Block mounting holes.

[0041] The claw piece of described unsealing claw 3 is provided with at least three pieces, and the unlocking boss outer diameter of claw piece bottom is greater than the inner diameter of sitting blockade ring 6, and the upper end of unlocking boss is provided with chamfer, is convenient to slide in and sits in the blockade ring 6, will Sit on the blockade ring 6 and stretch it out.

Embodiment 3

[0043] The upper outer wall of the central tube 2 is provided with a connecting step, the body of the connecting step is provided with an unsealing claw through the groove, and the outer wall is provided with threads to connect with the retaining ring 5; the liquid flow hole in the central tube 2 is connected to the bottom of the piston 13 Corresponding. The central pipe 2 blocks the unsealing claw 3 in the connection step of the upper outer wall while realizing the connection with the retaining ring 5 .

[0044] The unsealing claws in the connecting step of the central tube 2 match the number of claws of the unsealing claws 3 through the slots, and the outer wall of the central pipe 2 middle part is provided with an unsealing shear nail assembly groove and an unblocking block assembly groove, which are respectively connected with the unsealing claws. The unsealing scissors assembly hole at the lower part of the pawl 3 pawl sheet is connected with the unsealed shears 7 in the ...

Embodiment 4

[0046] The lower body of the setting claw 11 is a stepped cylinder, and the upper part is a claw piece. The number of claw pieces of the setting claw 11 is equal to that of the unsealing claw 3 and interlaced with the unlocking bosses of the unsealing claw 3. Connect with seat block ring 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com