Intelligent cutting machining process monitoring system and monitoring method thereof

A cutting and process monitoring technology applied in the new generation of intelligent manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

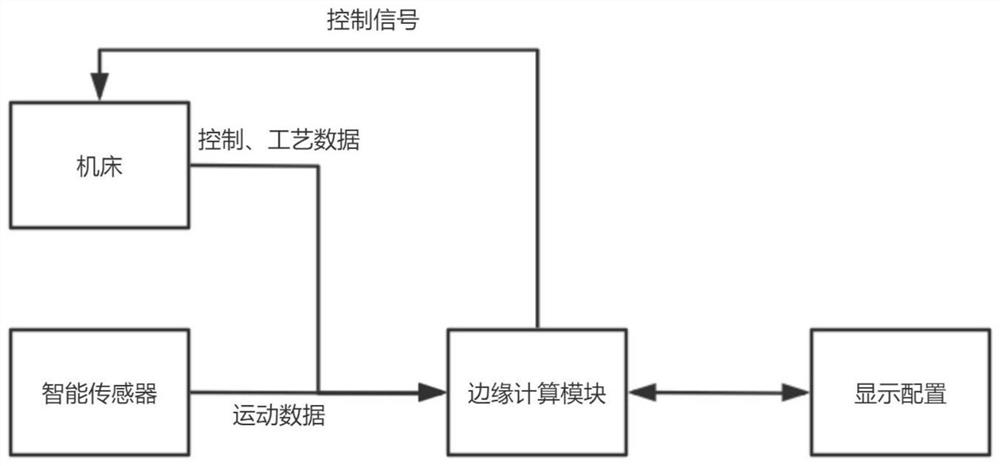

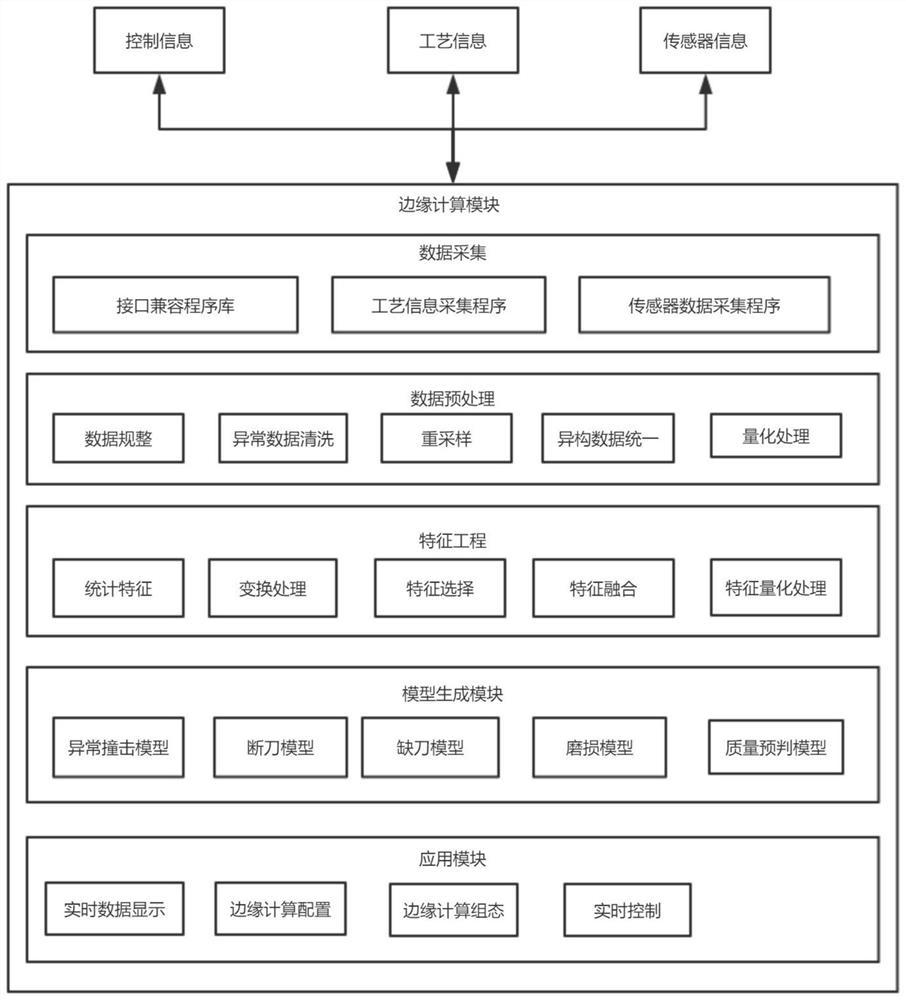

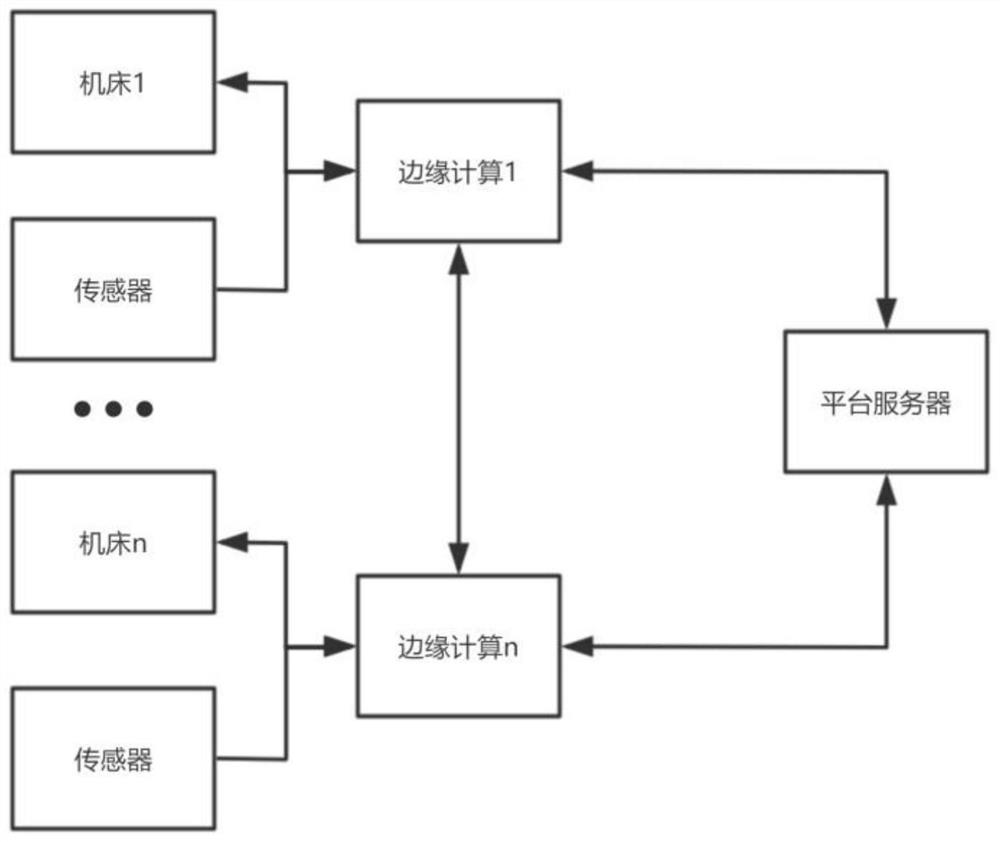

[0035] The invention discloses an intelligent cutting process monitoring system, which mainly includes a machine tool control module, an intelligent sensor, an edge computing module and a display configuration module. in the computing module. The intelligent sensor is installed on the spindle of the machine tool, which is connected with the edge computing module, directly senses the vibration acceleration signal of the machine tool equipment, and after internal signal processing, converts it into the speed information, acceleration information, gravity information and sound information of the collected machine tool, and transmitted to the edge computing module; the display configuration module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com