Electromechanical-hydraulic piston actuator and brake system

An actuator and piston-type technology, applied in the direction of brakes, brake transmissions, transmissions, etc., can solve problems such as uncertain re-connection, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In all figures, the same parts are indicated by the same reference numerals.

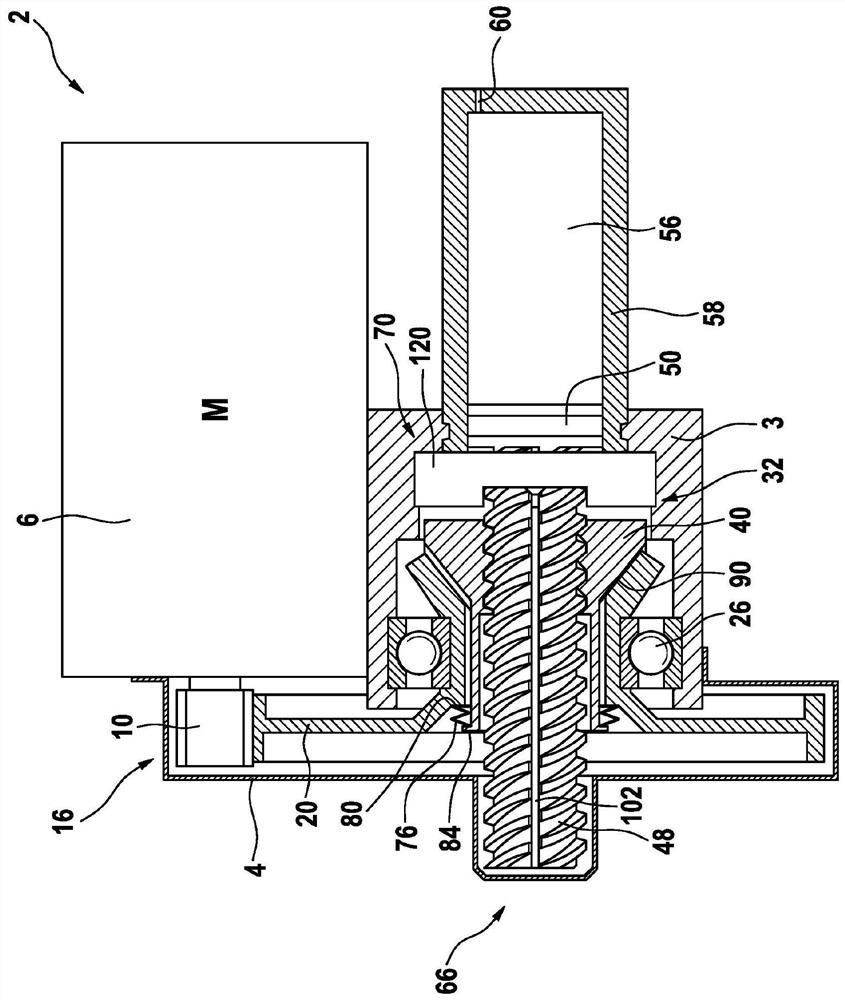

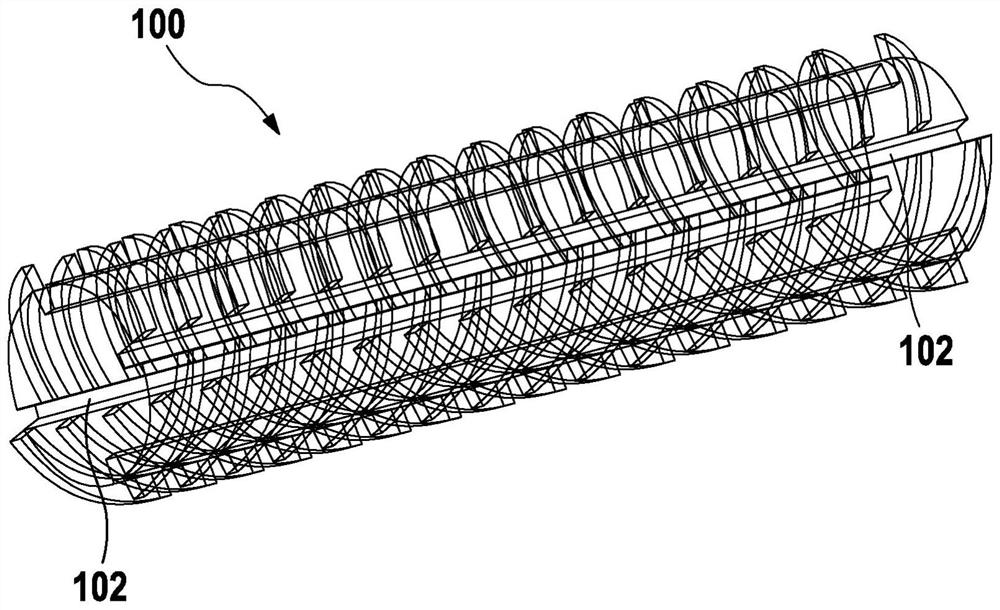

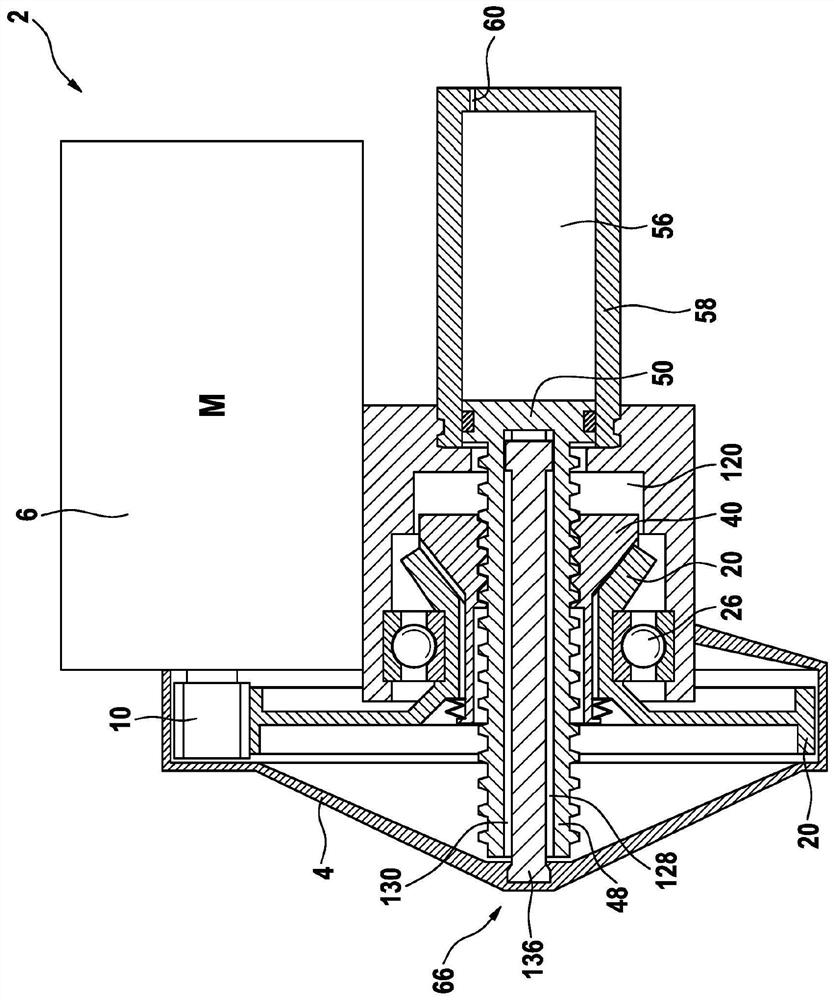

[0057] figure 1 The electromechanical-hydraulic piston actuator 2 shown in includes a housing with a load-bearing structure 3 , a transmission cover 4 and an electric motor 6 with a stator and a rotor 10 , which is coupled to a drive element 20 via a rotation-rotation transmission 16 , the rotation-rotation transmission mechanism at figure 1 is shown as a gear pair, but could just as easily be shown as a belt drive. When the rotor 10 rotates, the drive element 20 , which is rotatably mounted in a bearing 26 in the carrying structure 3 , is caused to rotate. The actuator 2 has a rotation-translation transmission mechanism 32 driven by a drive element 20 comprising a rotatable nut 40 and a screw 48 arranged not to rotate but movable in its axial direction. The piston 50 is coupled with the screw 48 in the axial direction.

[0058] To build up the pressure, the piston 50 is movable in a hydr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com