Method and device for identifying faults in a pneumatic system

A compressed air, failure technology, applied in fluid pressure actuation system testing, fluid pressure actuation system components, mechanical equipment, etc., can solve problems such as impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

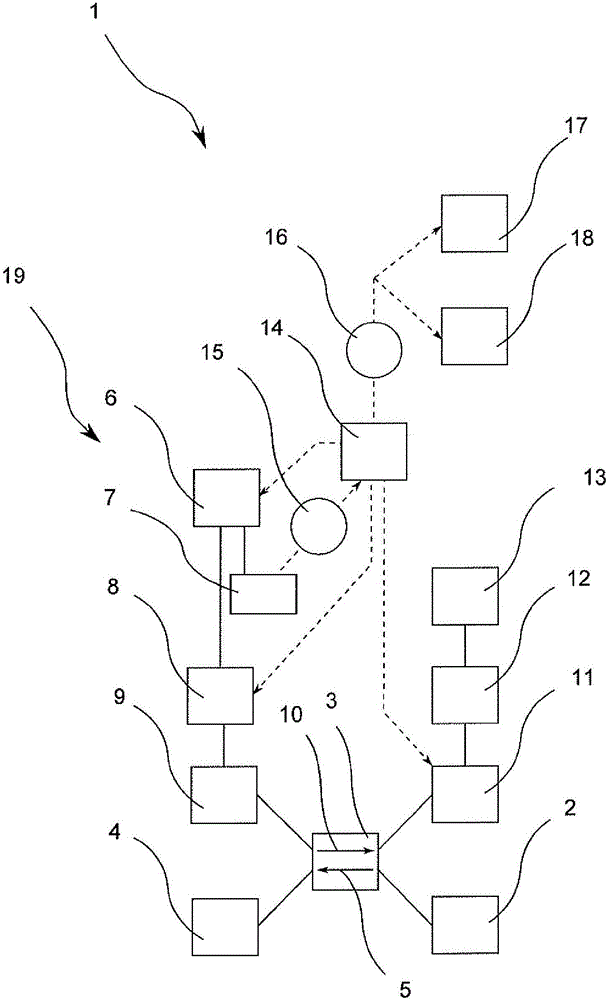

[0025] according to figure 1 , inside a compressed air system 1 of a motor vehicle (not shown further), a compression system 2 is connected on the output side to a dryer filter element 3 , which in turn is connected to a consumer system 4 .

[0026] In the operating state, the compression system 2 pumps possibly moist air in the operating direction 5 through the dryer filter 3 into the consumer system 4 , where it is dried until the dryer filter 3 is saturated.

[0027] In order to regenerate or dry the possibly saturated dryer insert 3 , in regeneration mode, dry air is conducted from the regeneration air reservoir 6 via the solenoid valve 8 and the non-return valve 9 into the dryer insert 3 . The dryer filter insert is then flowed through by drying gas in a regeneration direction 10 opposite to the running direction 5 , so that the regeneration or drying function of the dryer filter insert is carried out. The air flow is then discharged to the surroundings through outlet va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com