Overturning device for pot-stewed meat sausage processing

A technology of turning device and braised sausage, which is applied in application, baking, oil/fat baking, etc., can solve the problems of low efficiency and manpower consumption, and achieve the effect of uniform heating, meeting the needs of use, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

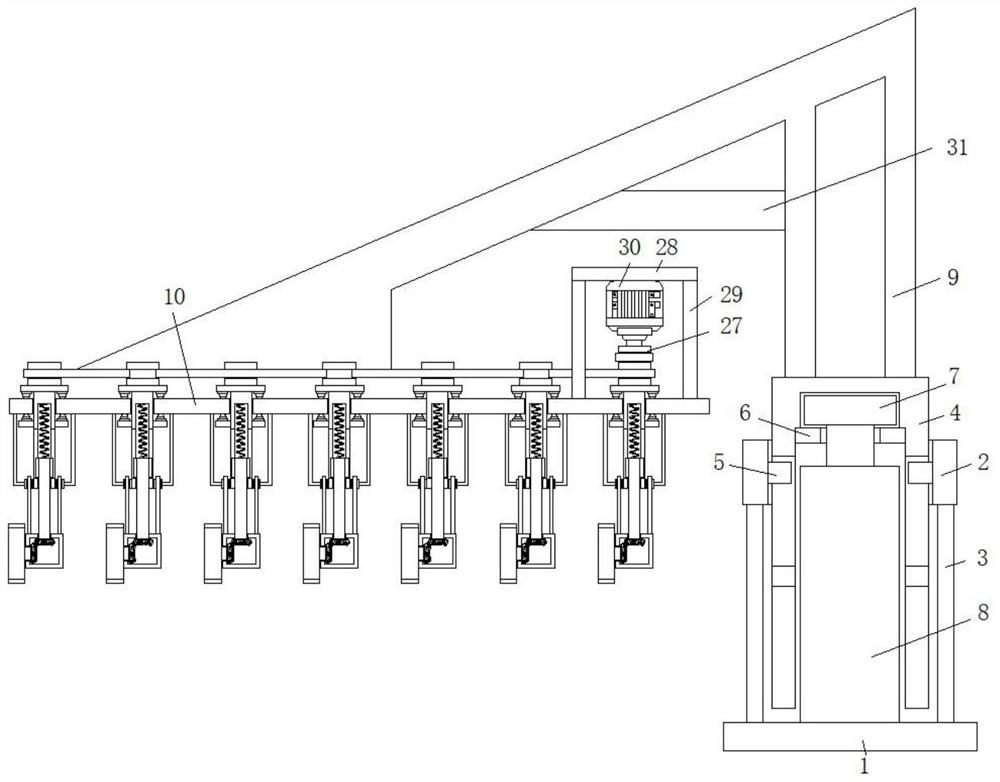

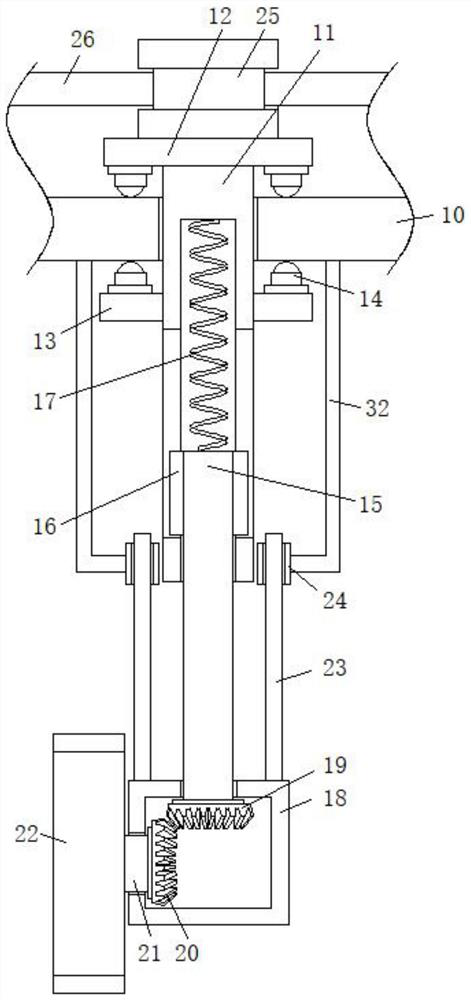

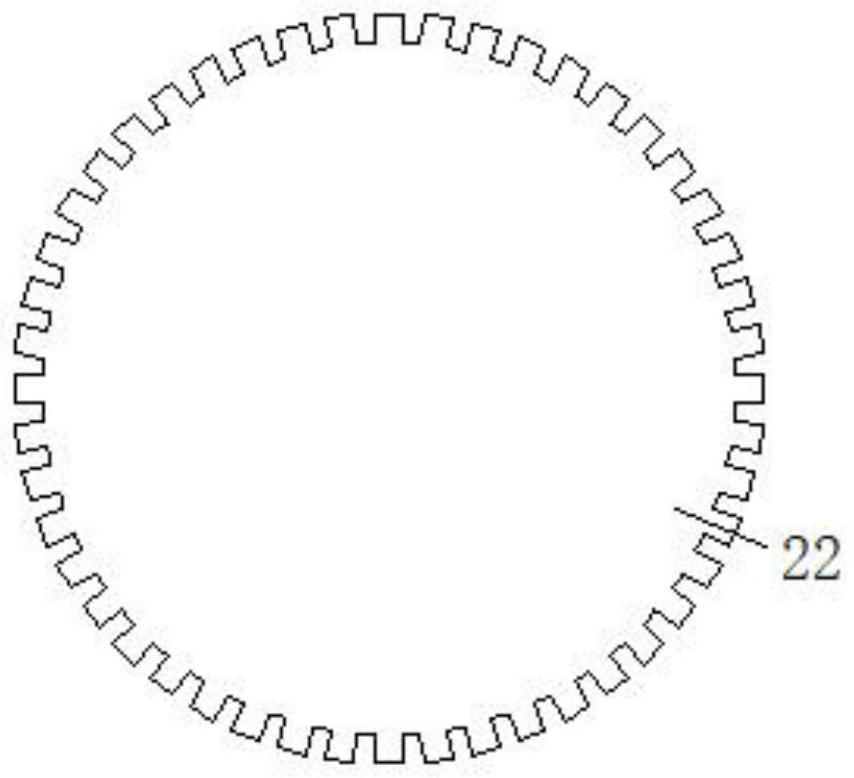

[0024] refer to Figure 1-3 , a turning device for braised sausage processing, comprising a mounting base 1, a fixing ring 2 is arranged vertically above the mounting base 1, a support column 3 is arranged between the bottom side of the fixing ring 2 and the mounting base 1, and the fixing ring 2 The inner slide passes through the track cylinder 4, the cylinder body of the track cylinder 4 is provided with a track groove, the inner wall of the fixed ring 2 is fixedly connected with a guide column 5, and one end of the guide column 5 extends into the track groove, and the bottom end of the track cylinder 4 is Open-shaped structure, and the top inner wall of the track cylinder 4 is provided with a circular groove, the inner wall of the opening at the bottom of the circular groove is fixedly connected with a sealing ring 6, and a rotating circular plate 7 is arranged in the circular groove, and the top side of the mounting seat 1 is fixed and installed by bolts There is a cylinde...

Embodiment 2

[0029] like Figure 1-3 As shown, the present embodiment is basically the same as Embodiment 1. Preferably, the top side of the top plate 12 is fixedly connected with a pulley 25, and a transmission belt 26 is transmitted between each row of pulleys 25, and a transmission belt 26 is transmitted between each row of pulleys 25. Belt two 27, the vertical top of hanging plate 10 is provided with mounting plate 28, is fixedly connected with support frame 29 between the bottom side of mounting plate 28 and hanging plate 10, and one side of mounting plate 28 is fixedly equipped with motor 30 by bolt, The output shaft of the motor 30 is in drive connection with one of the pulleys 25 .

[0030] In this embodiment, the motor 30 is used to complete the synchronous rotation of each drum 22, which saves time and effort, and has high efficiency and good effect.

Embodiment 3

[0032] like Figure 1-3 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the top side and the vertical side of the power cover 18 are respectively provided with through holes for the sliding rod 15 and the circular shaft 21 to pass through.

[0033] In this embodiment, the power cover 18 is under the restriction of the vertical track rod 23 and the track vertical tube 24, and the power cover 18 maintains its posture when following the bevel gear one 19 to move in the vertical direction.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap