battery cleaning device

A technology for cleaning devices and batteries, applied in cleaning methods and utensils, cleaning methods using gas flow, electrostatic effect separation, etc., can solve the problem that the connection part of the towel battery cannot be cleaned thoroughly and is large, and it takes 2 hours to clean a group, which affects maintenance. It can improve the dust collection capacity, reduce the difficulty of operation, and enhance the adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

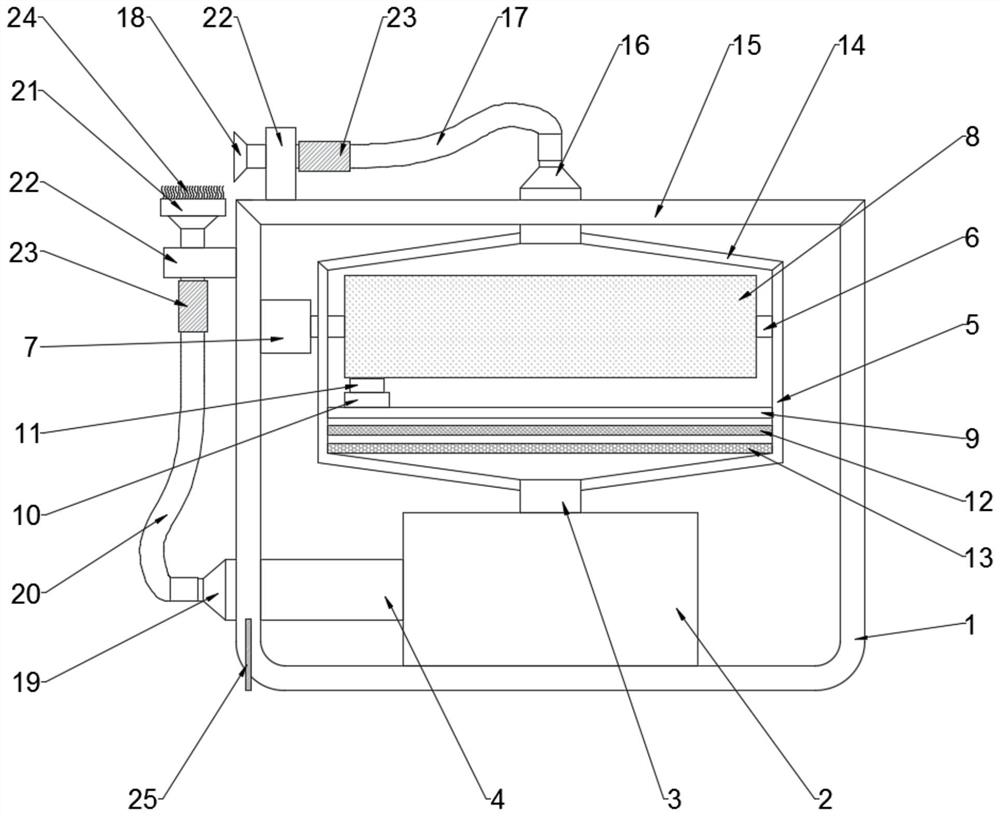

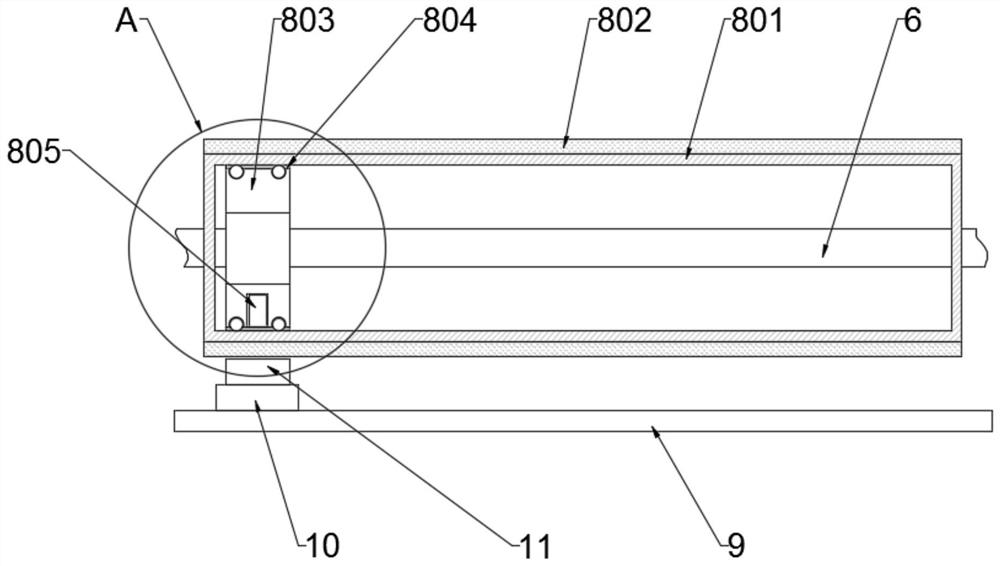

[0040] see figure 2 , a battery cleaning device, comprising a housing 1, an air pump 2 is fixed on the inner bottom of the housing 1, an air suction pipe 3 is connected to the air suction port of the air pump 2, an air outlet pipe 4 is connected to the air outlet of the air pump 2, and the housing The upper side of the body 1 is provided with a dust collection bucket 5, the bottom of the dust collection bucket 5 is connected with the suction pipe 3, the interior of the dust collection bucket 5 is horizontally provided with a rotating shaft 6, and the inner wall of the housing 1 is fixed with a drive motor 7, The output end of the driving motor 7 is connected to one end of the rotating shaft 6, the electrostatic dust collection cylinder 8 is fixedly sleeved on the rotating shaft 6, the upper side of the dust collecting bucket 5 is clipped with a dust collecting bucket cover 14, and the upper side of the housing 1 is clipped Connected with the housing installation cover 15, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com