Compression device for construction solid waste treatment

A construction solid waste and compression device technology, which is applied in grain processing, construction waste recycling, solid waste removal, etc., can solve the problems of not being able to realize the automatic refilling of the crushing box, affecting the compression efficiency, and requiring manual transfer, etc., so as to avoid blockage , Improve the crushing efficiency and speed up the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

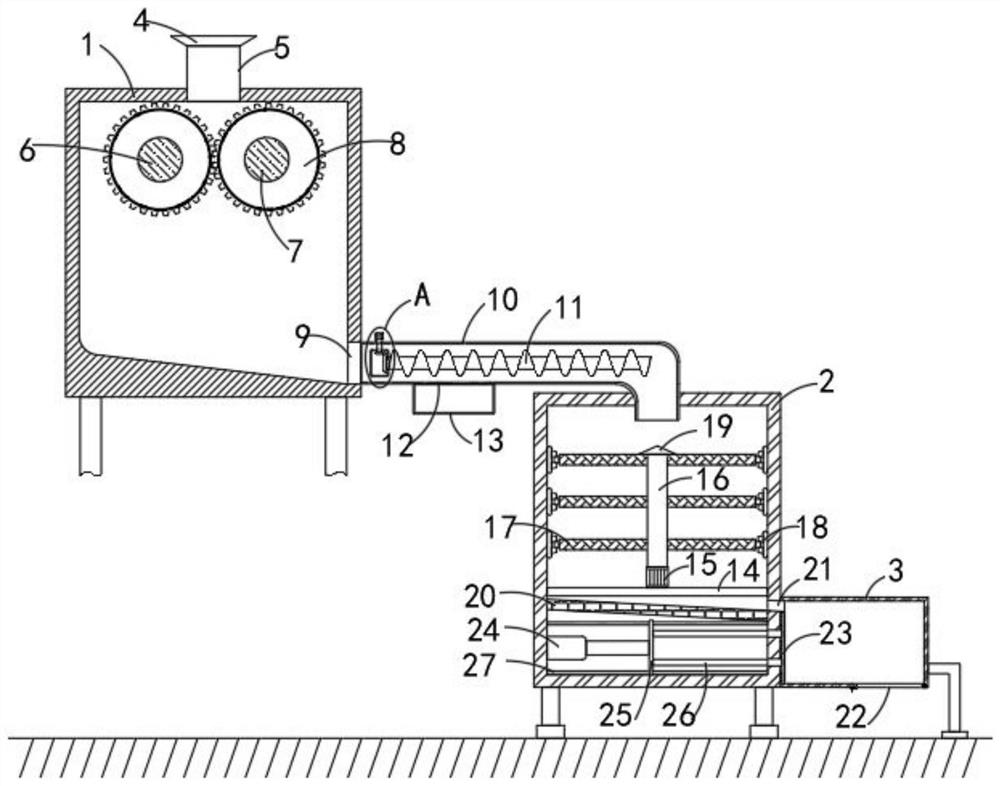

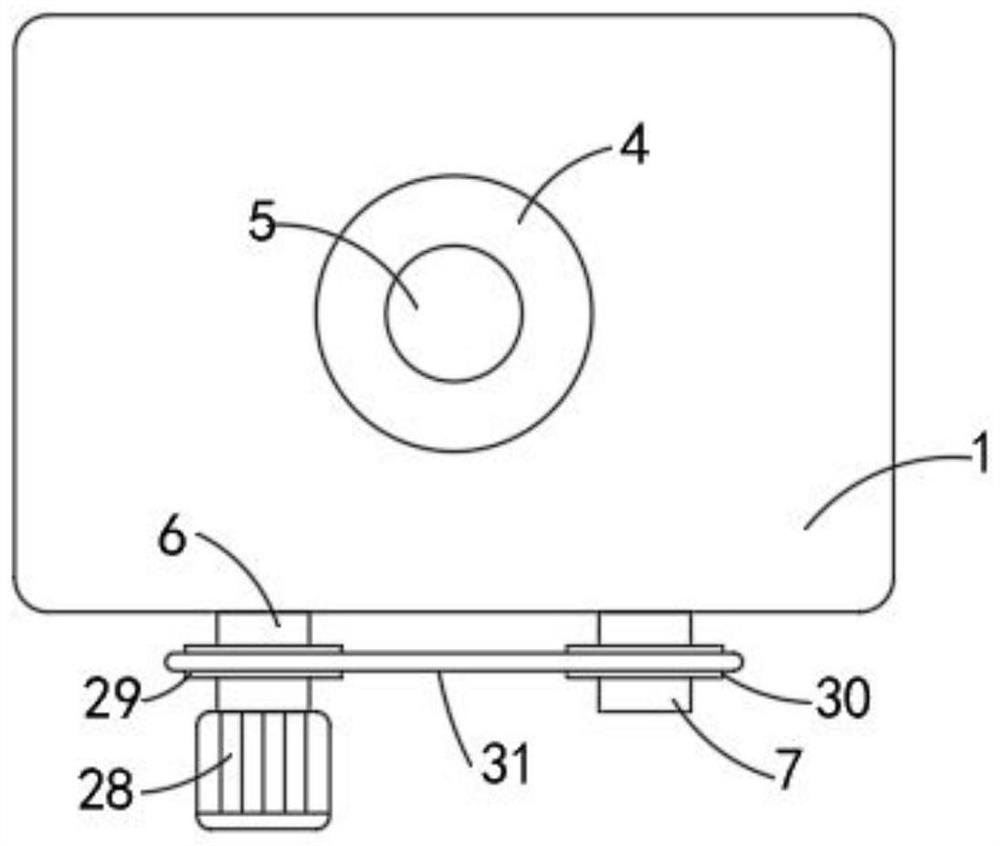

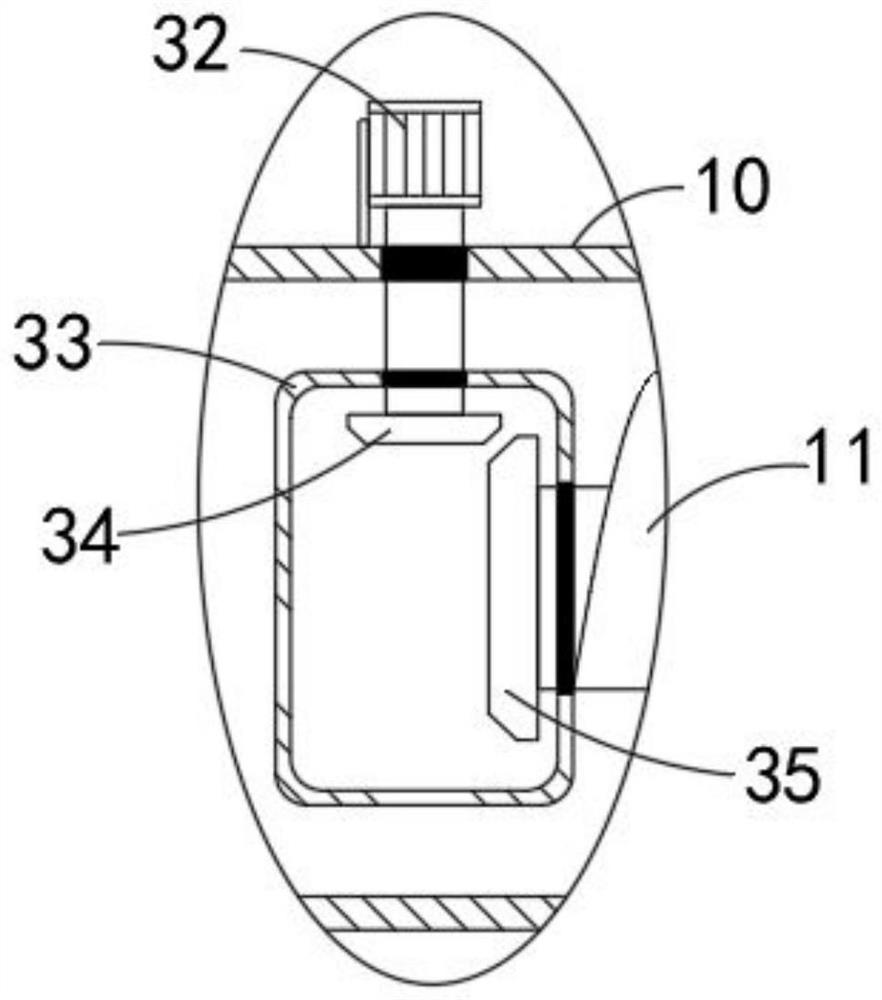

[0023] refer to Figure 1-4 , a compression device for construction solid waste treatment, comprising an automatic feeding box 1, a crushing box 2 and a compression box 3, the crushing box 2 is located between the automatic feeding box 1 and the compression box 3, and the top of the automatic feeding box 1 is fixedly connected There is a feed pipe 5, and a matching feed cover 4 is provided at the top opening of the feed pipe 5. The inner wall of the feed cover 4 is smooth and polished. The setting of the feed cover 4 improves the feeding rate of the feed pipe 5, and automatically A primary crushing device matching the opening of the lower end of the feed pipe 5 is ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap