Mining mixer truck rotary automatic aligning device

An automatic centering and mixer truck technology, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as abnormal noise, damage to the rotary device, excessive bonding of the outer ring and inner ring, etc., to achieve The effect of prolonging the service life and ensuring the safety of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

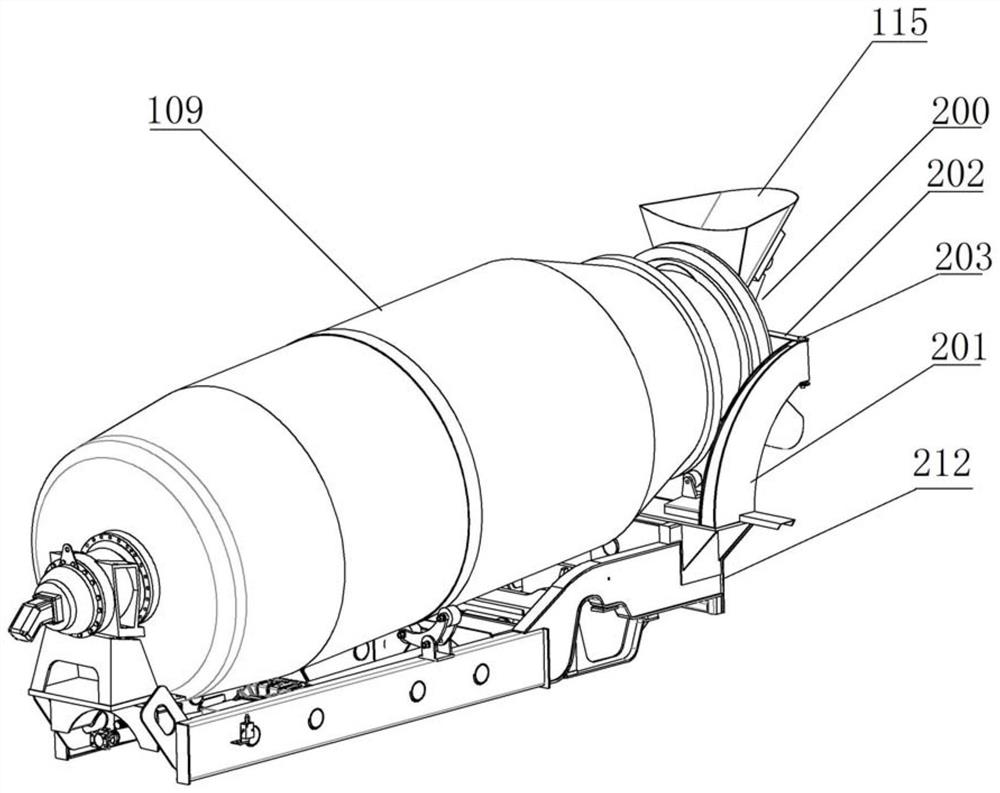

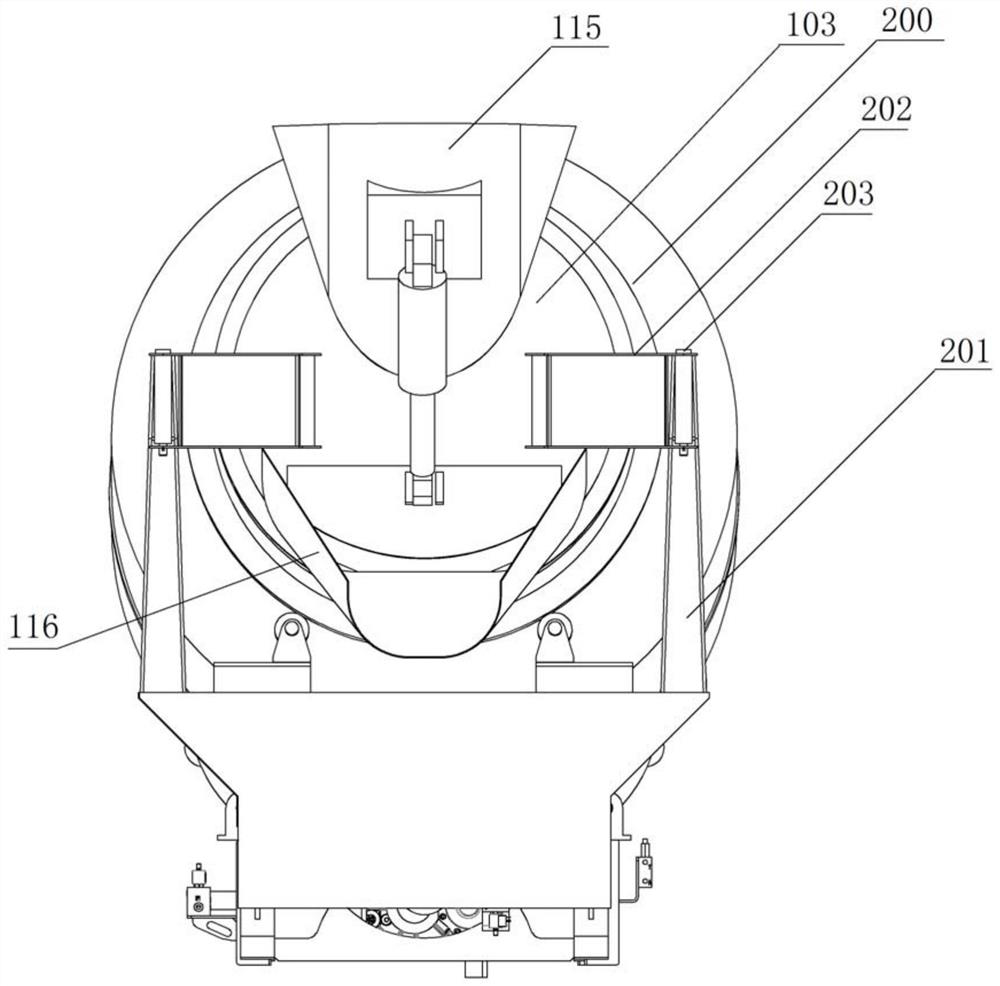

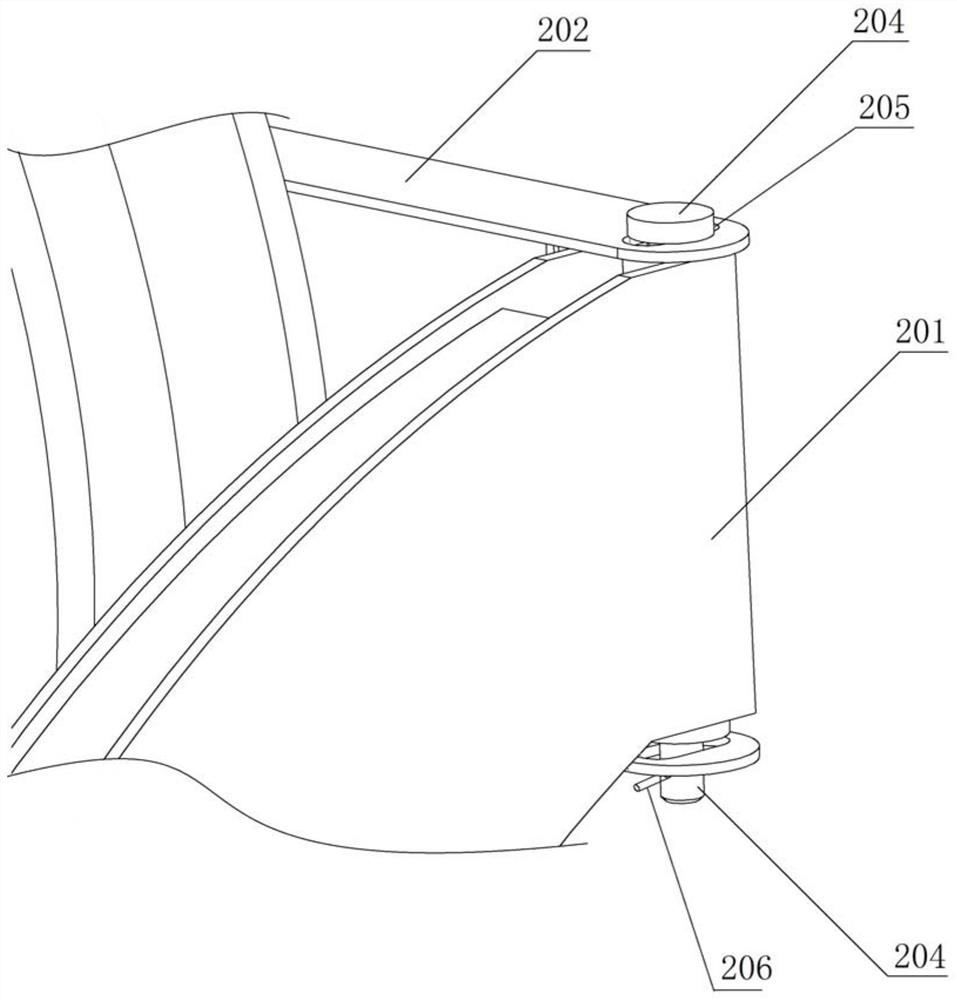

[0025] Such as figure 1 with figure 2 As shown, it is a rotary automatic centering device for a mining mixer truck, including a car body bracket 212, an inner ring used to connect to the mixing drum 109, and a cover arranged on the inner ring and rotatably connected with the circumferential outer wall of the inner ring The feeding and discharging unit 200 also includes a floating self-aligning structure, one end of the floating self-aligning structure is flexibly connected to the feeding and discharging unit 200, and the other end is connected to the car body bracket 212; the feeding and discharging unit 200 includes an outer ring 102 and a sealed tail cover 103 ( In the figure, the inner ring is covered by the sealing end cap 103, so the inner ring is not shown), the circumferential inner wall of the outer ring 102 is rotationally connected with the circumferential outer wall of the inner ring, and the sealing end cap 103 is connected to the outer ring by circumferentially d...

Embodiment 2

[0030] The present embodiment is similar to embodiment 1, and its difference is:

[0031] In this example, if Figure 4 As shown, the floating self-aligning structure is an elastic compensating assembly 207 respectively connected to the two sides of the outer ring 102 close to the end of the vehicle body bracket 212; Figure 5 As shown, the elastic compensation assembly 207 includes a support bracket 208, a reset device 209 and a support 210. The support bracket 208 is connected to the circumferential outer wall of the outer ring 102, the support 210 is installed on the vehicle body bracket 212, and one end of the reset device 209 is connected to the support Holder 208, the other end is connected to support 210; Reset device 209 is a stainless steel spring; In this embodiment, one side of sealing tail cap 103 is also connected with outer ring 102 by hinge 211, is convenient to open sealing tail cap 103, replaces seal .

[0032] As an alternative, the elastic compensating ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com