Tunnel lagging jack and construction method thereof

A construction method and technology for tunnels, which are applied in tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve the problems of high storage and transportation difficulty, rigid support vault pressure, and complicated steel arch fabrication, etc. The strength of the arch frame and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

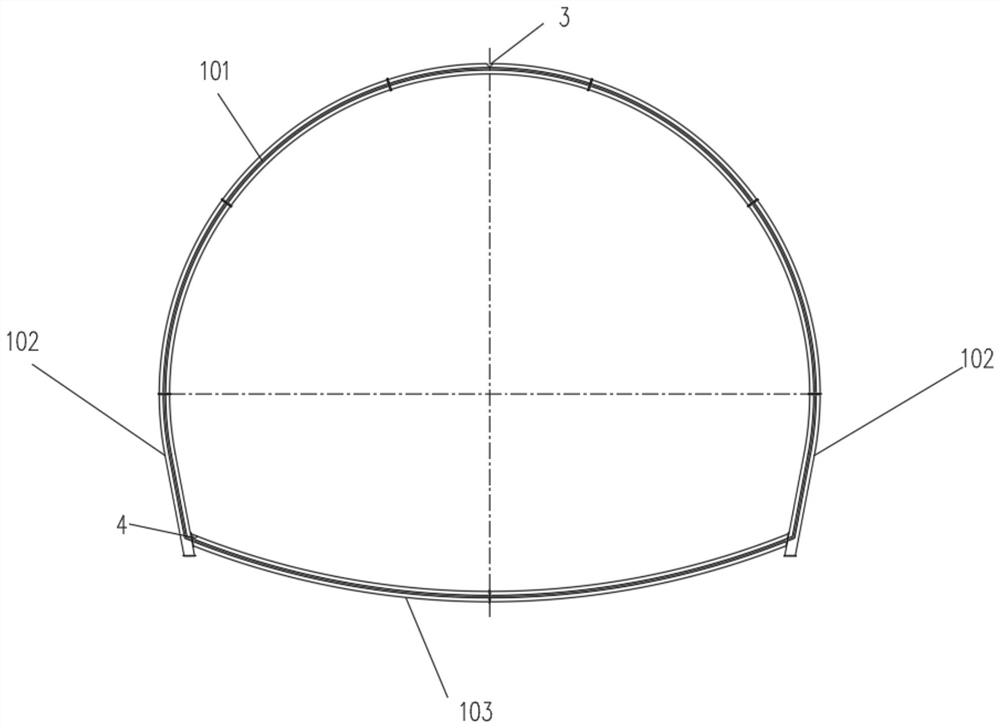

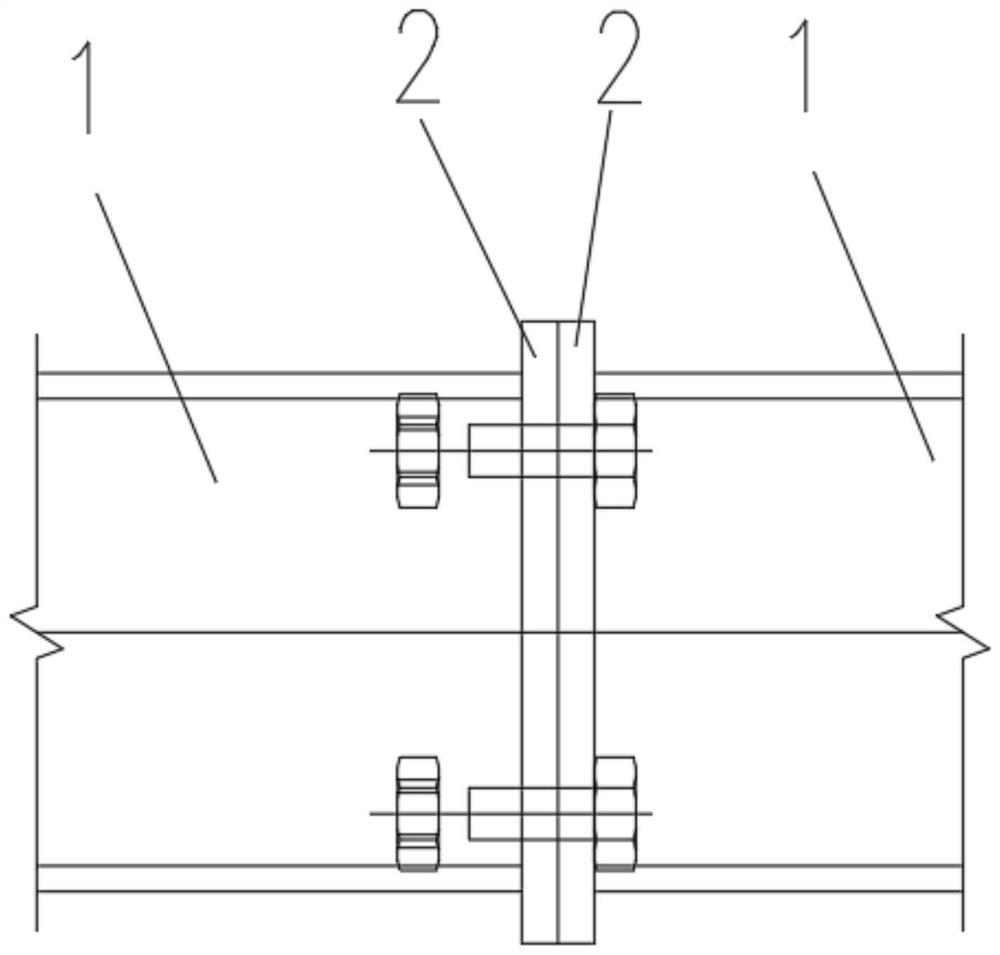

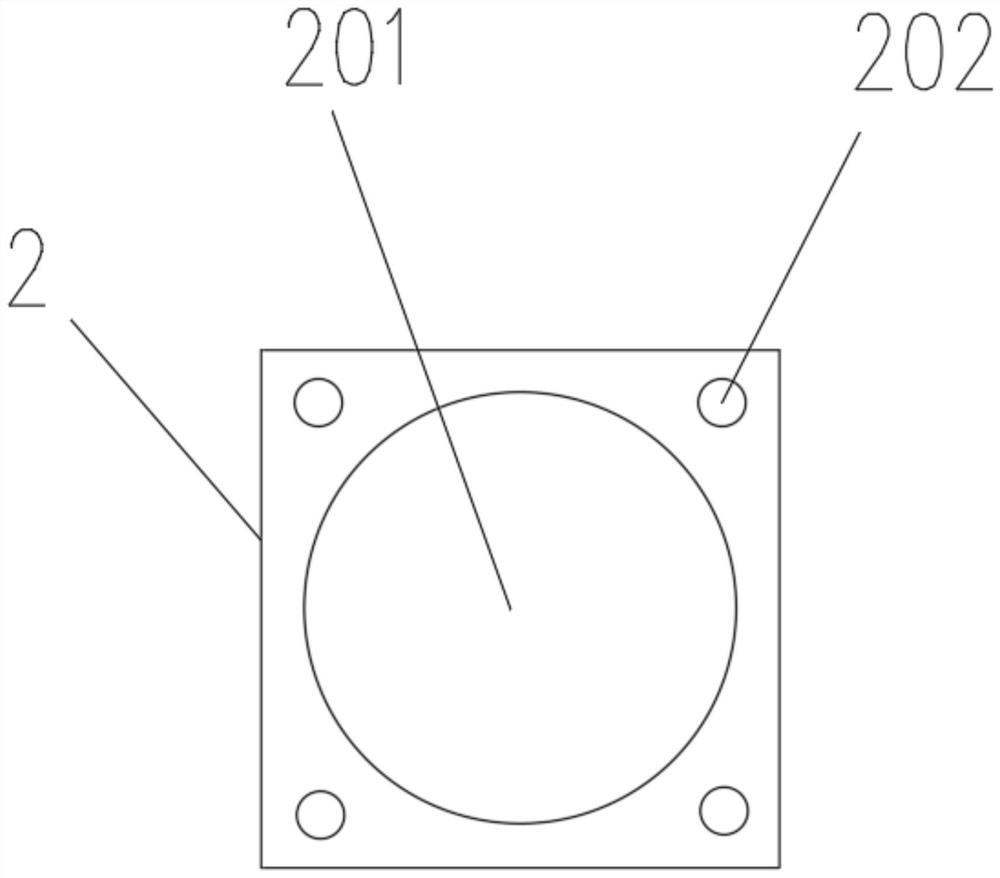

[0028] As shown in the drawings, the tunnel arch frame of the present invention includes several segmental arch frames 1, and several segmental arch frames 1 are connected to form a tunnel arch frame. The segmental arch frame 1 is a tubular structure, and the segmental arch frames The end of the segmented arch 1 where the frame 1 and the segmented arch 1 meet is provided with a connecting plate 2 , and the segmented arch 1 and the segmented arch 1 are connected through the connecting plate 2 . The structure of the tunnel arch is set in a tubular shape, so that prestressed components, such as bellows 5 and prestressed steel wire bundles, can be arranged in the tube of the segmented arch 1, so that the tunnel arch can be prestressed and the tunnel arch can be guaranteed. Rigidity and strength, to further improve the stability of the tunnel arch, the segme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com