Rock core splitting device

A core and core tube technology, which is applied in the field of mineral exploration and geological exploration, can solve problems such as low work efficiency, operator injury, and high difficulty, and achieve the effects of eliminating dust pollution, reducing safety hazards, and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

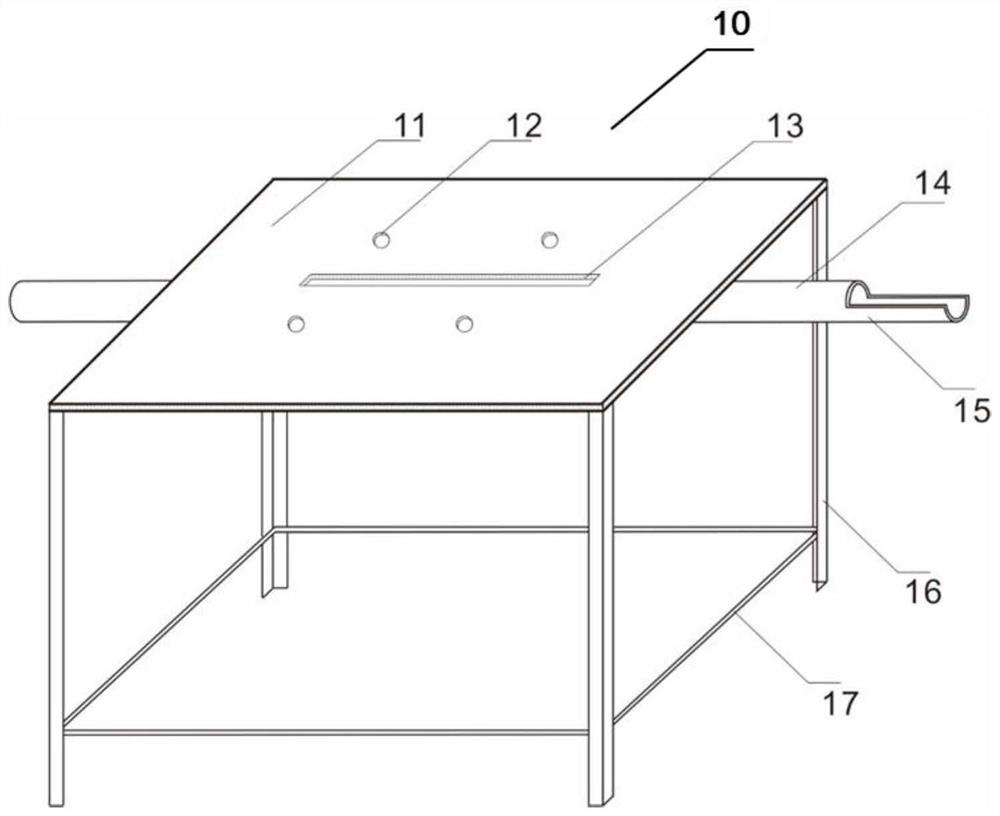

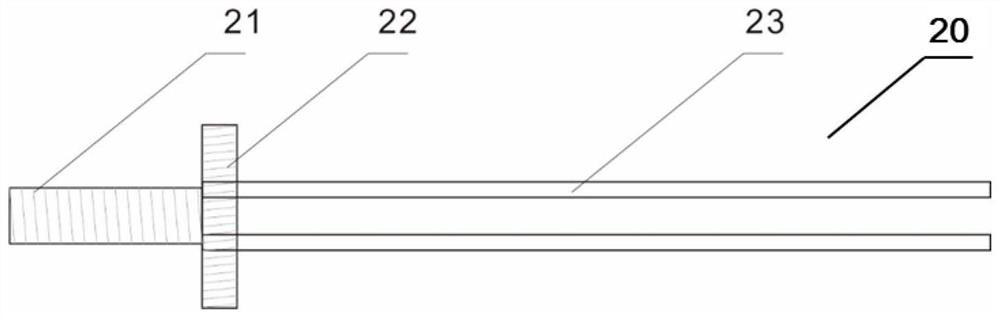

[0034] Such as Figure 1-3 As shown, a kind of core splitting device provided by the present invention includes a splitting support 10 and a core pushing rod 20, and the pushing rod 20 is detachably moved and sleeved inside the splitting support 10. The bracket 10 cooperates with the pusher rod 20 for core splitting.

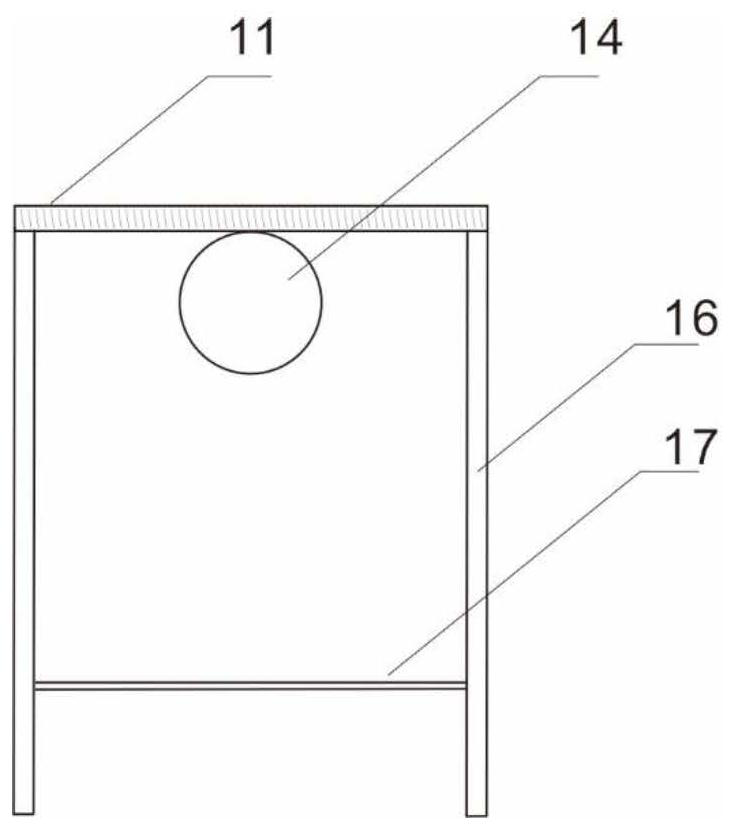

[0035] Such as figure 1 with image 3 As shown, the splitting support 10 includes a support table 11, a cutting machine fixing screw hole 12, a cutting piece on the table through an opening 13, a core tube 14, a half core tube 15, support legs 16 and a support fixing beam 17.

[0036] Such as figure 1 As shown, the center position of the top of the support table 11 is provided with a table cutting piece through opening 13, and the size of the table cutting piece through the opening 13 is determined according to the diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com