Method and system for accurately moving insulating bucket of distribution network hot-line work electric bucket arm vehicle

A technology for live work and insulated buckets, which is applied in control/regulation systems, motor vehicles, non-electric variable control, etc. It can solve the problems of automatic adjustment and poor visualization of quantitative bucket trucks, and improve the efficiency of live work. The success rate, the automation of robot operation, and the effect of improving the efficiency of on-site operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

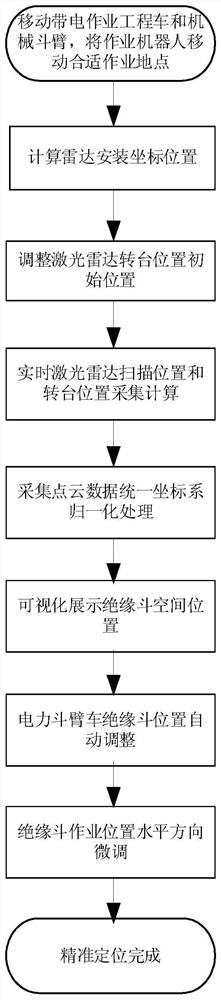

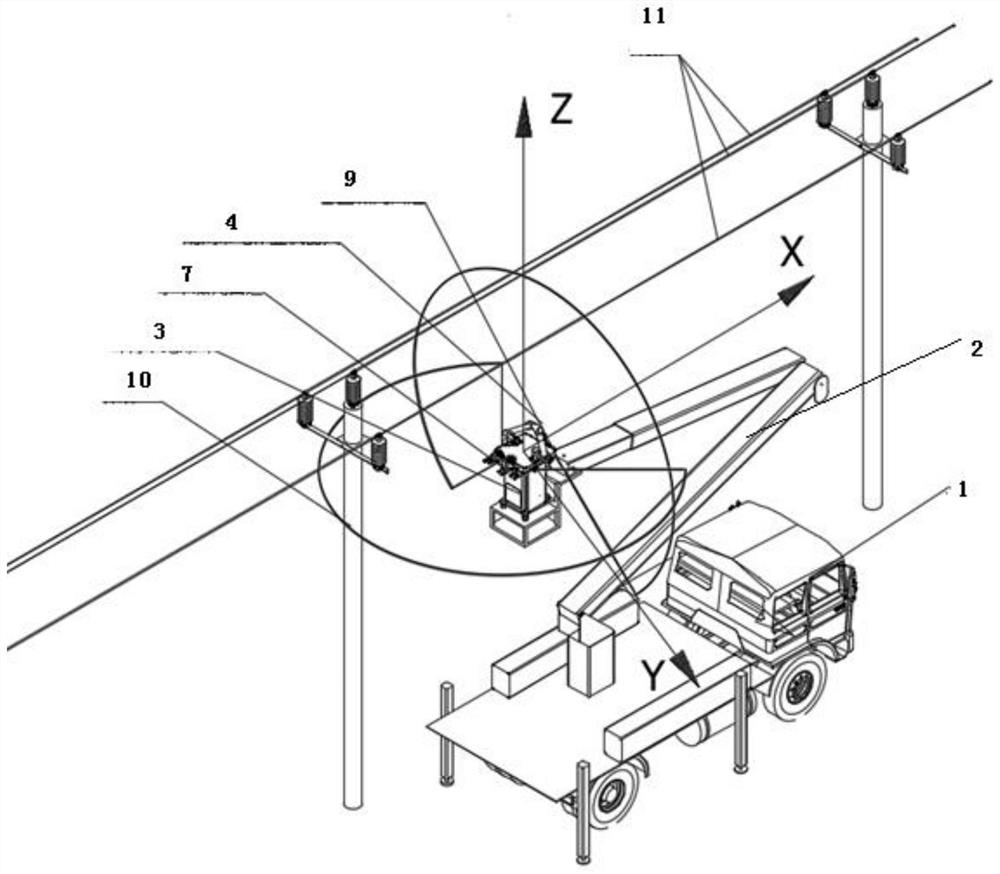

[0044] A method for accurately moving the insulated bucket of the electric bucket arm truck for live work in the distribution network according to the present invention takes the precise positioning of the live work position of the triangular line of the distribution network (wiring mode in the operation scene) by the live work robot of the distribution network as an example. The operation electric arm truck moves precisely.

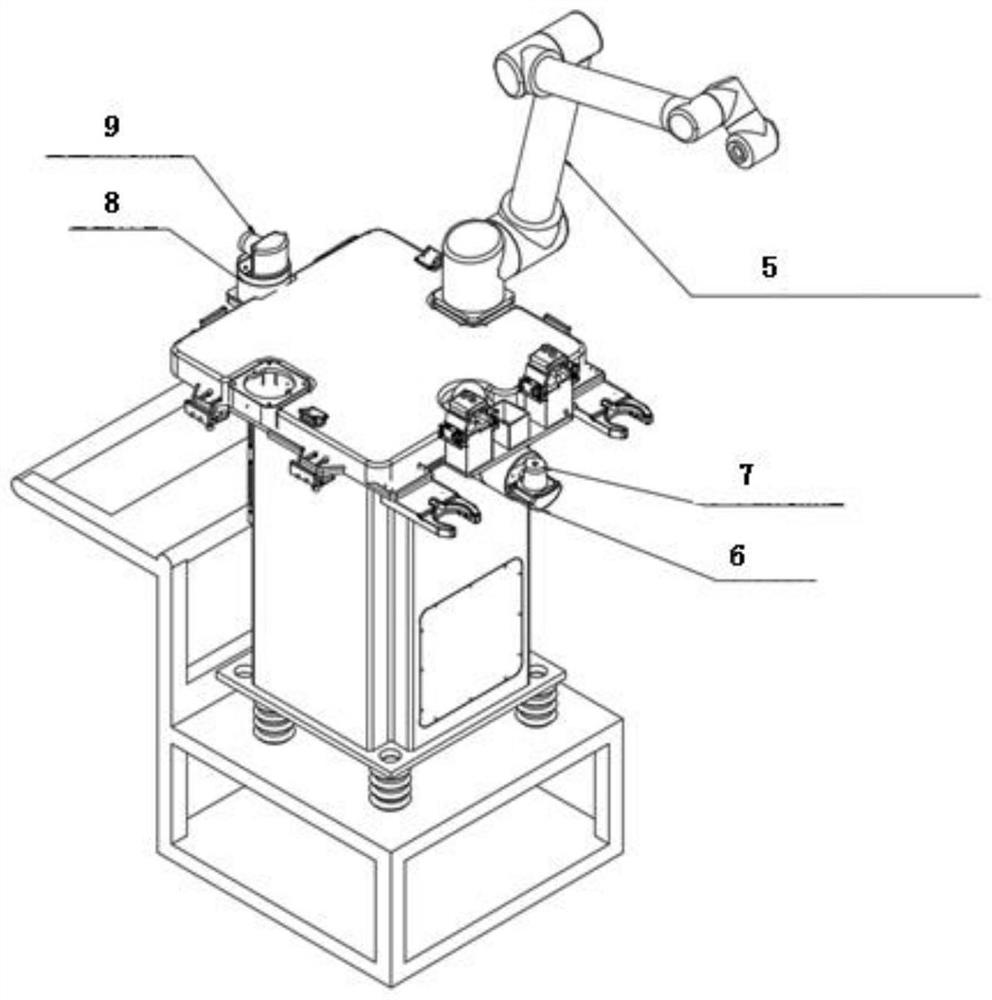

[0045] see figure 2 and image 3 As shown, the power bucket arm 2 is installed on the power insulation bucket truck 1, the power insulation bucket 3 is installed at the end of the power bucket arm 2, and the distribution network live working robot 4 (robot for short) is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com