Multi-motor control circuit of thermal infrared imager

A multi-motor control, infrared thermal imager technology, applied in the field of infrared detection, can solve the problem that the drive control circuit cannot be compatible with multiple motors at the same time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

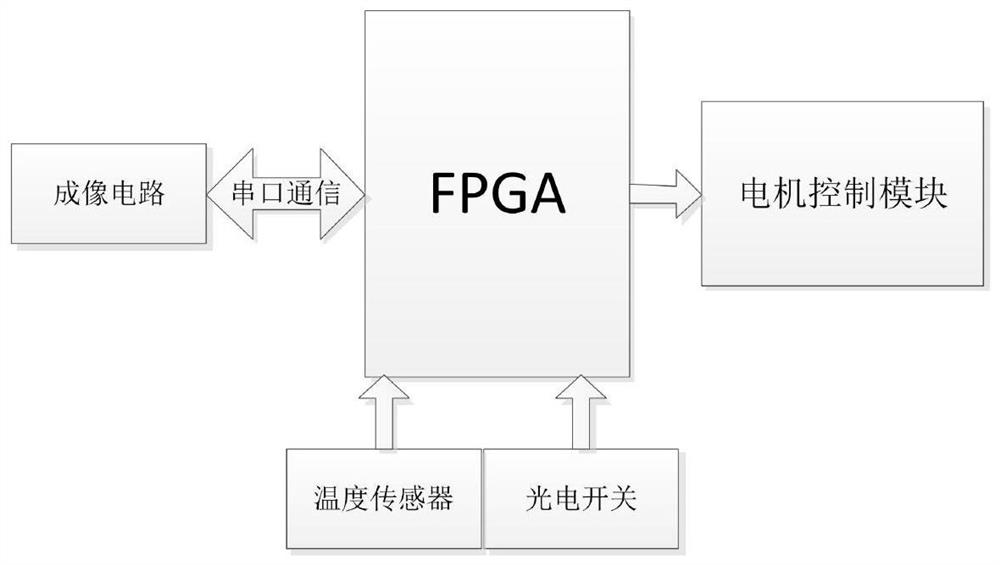

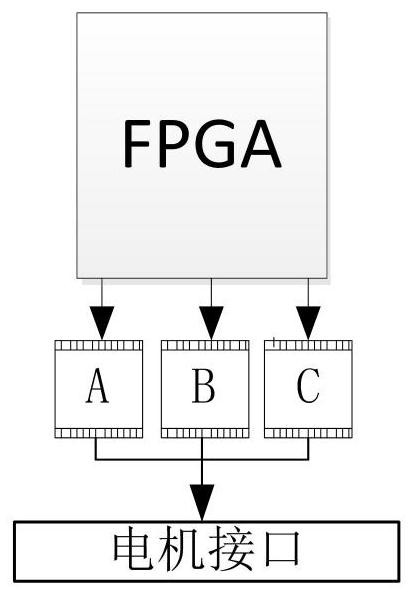

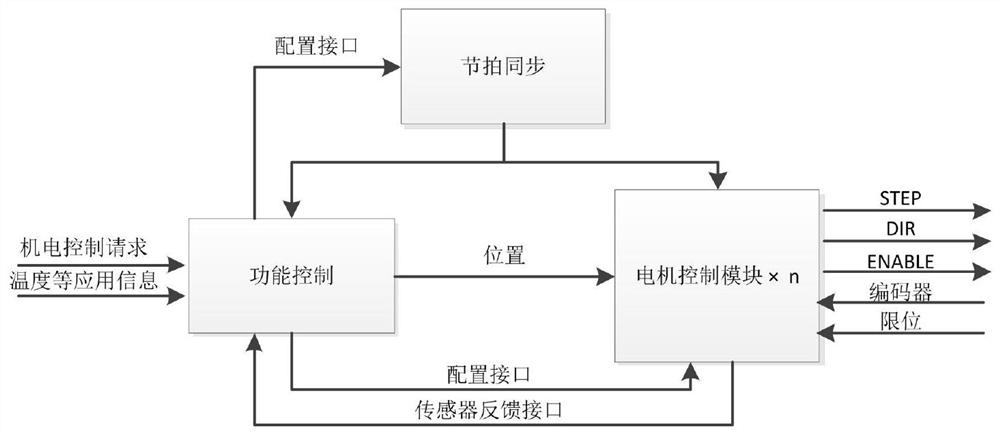

[0030] The hardware circuit in the existing infrared thermal imager uses PPGA as the processor imaging circuit as the core, and the motor control generally uses ARM and MCU as the processing core. It is necessary to unify the processor type to reduce the types of software and hardware development and save development resources. At the same time, in order to realize continuous zooming, the circuit must be realized by cooperation of multiple motors, and a special motor drive circuit needs to be designed. In addition, the types of motors in the infrared thermal imager are divided into focusing motors and field of view motors according to the functions of the motors. Generally, the stepping motor is used to realize the focusing function, and the DC motor is used to realize the field of view switching function. The number and position of stepper motors and DC motors are designed according to the needs of the thermal imager, so the drive control circuit that meets the needs of variou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com