Metal plate and processing technology thereof

A processing technology and metal plate technology, applied in printing plate preparation, rotary printing machine, printing, etc., can solve the problems of large mesh limitations, low metal plate precision, single graphics, etc., to achieve full and clear patterns and metal plate precision High, sufficient ink volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

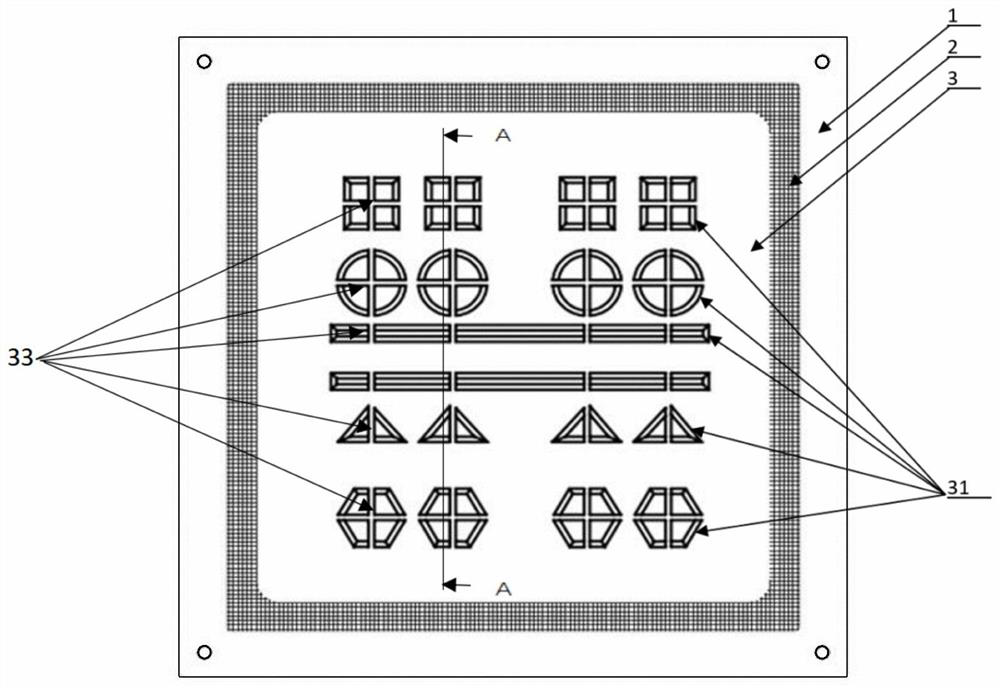

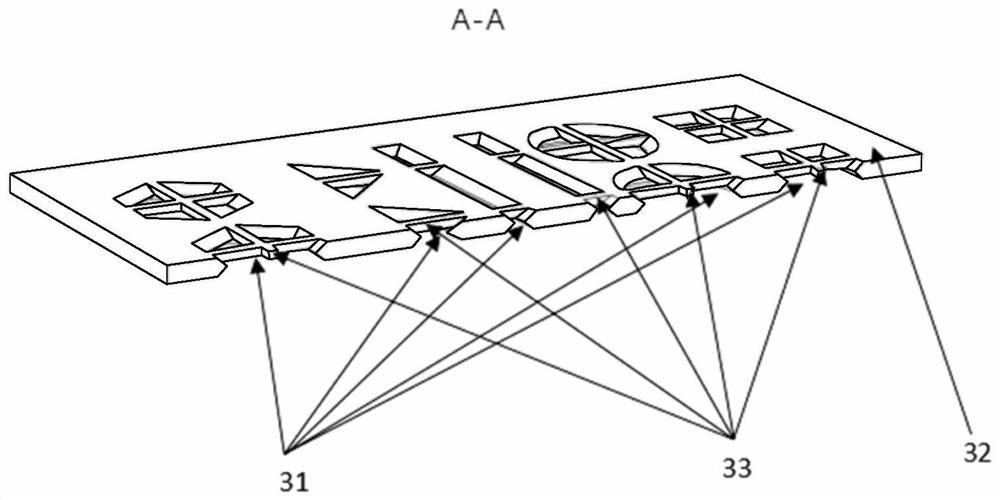

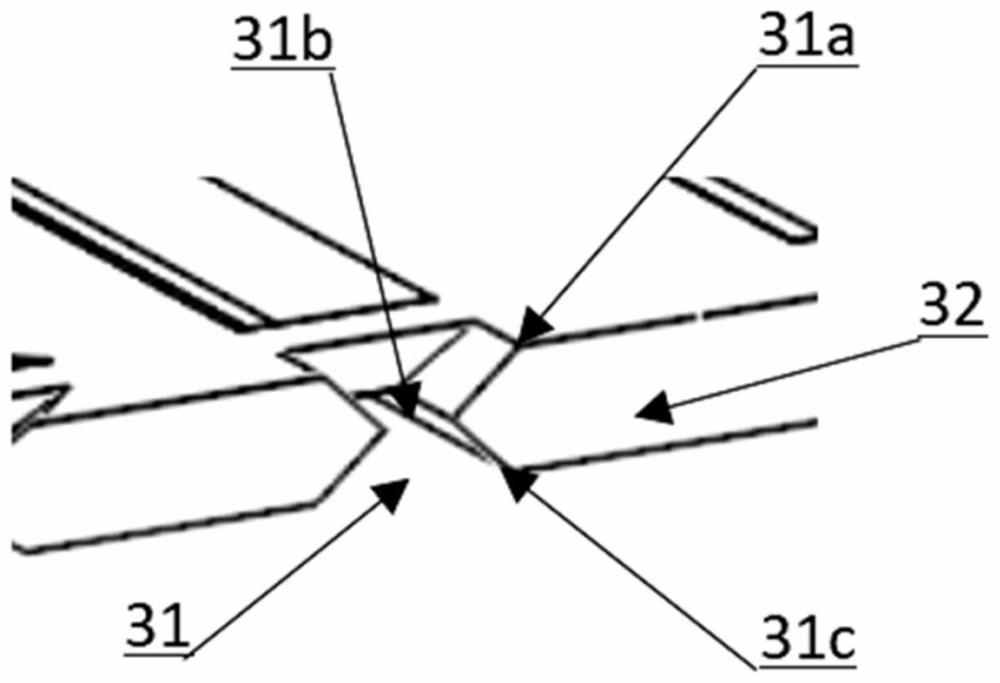

[0055] combine Figure 1-4, a metal plate, including a metal sheet 3, a screen 2 and a screen frame 1, the metal sheet 3 is connected and fixed on the screen frame 1 through the screen 2, and a printing channel 31 is arranged on the metal sheet. The printing channel 31 is surrounded by the non-pattern area on the metal sheet. Connecting units 33 are arranged at intervals along the extending direction of the printing channel 31; the printing channel 31 includes an upper opening 31a, a middle opening 31b, and a lower opening 31c sequentially connected from top to bottom, and the width of the middle opening 31b is the same as the printing design. The width dimensions of the patterns match, and the upper opening 31a and the lower opening 31c are wide-mouthed. Further preferably, 0

[0056] In this embodiment, preferably, the width of the upper...

Embodiment 2

[0059] This embodiment also discloses a raw metal plate processing technology, including the following steps

[0060] S1: Pretreat the surface of the metal sheet 32 by selecting a metal sheet 32 with a thickness ranging from 0.005 to 0.2 mm; preferably, the step of surface pretreatment of the metal sheet 32 includes removing grease and other dirt on the surface of the metal sheet.

[0061] S2: a layer of etching photosensitive material is attached to both sides of the metal sheet 32;

[0062] S3: Exposure: Expose the design patterns on both sides of the metal sheet 32;

[0063] S4: Developing: performing a developing operation on both sides of the exposed metal sheet 32;

[0064] S5: Etch both sides of the developed metal sheet 32; specifically, in this embodiment, in the process of etching the upper opening 31a, the middle opening 31b, and the lower opening 31c of the printing channel 31, the etching time and the etching time can be adjusted. The temperature, pressure...

Embodiment 3

[0069] This embodiment also discloses a metal screen processing technology, including the following steps

[0070] S1: select metal sheets within the thickness range of 0.005-0.2 mm, and perform surface pretreatment; including cleaning the surface of the metal sheet 32, removing grease and other dirt on the surface of the metal sheet 32.

[0071] S2: Carry out laser engraving patterns on one surface of the metal sheet 32, and the depth of the pattern on this surface and the width of the cross-sections of regions with different depths are controlled and obtained by adjusting the laser power and the number of engraving times.

[0072] S3: Turn over the metal sheet 32, and perform corresponding laser pattern engraving on the other surface of the metal sheet 32, and perform corresponding pattern engraving on the other surface of the metal sheet 32 after the laser is precisely aligned. In this embodiment, during the process of engraving the upper opening 31 a , the middle opening...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com