Sanitary towel bleaching wastewater collecting and filtering equipment

A technology of waste water collection and filtration equipment, applied in the field of bleaching equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 To attach Figure 5 Shown:

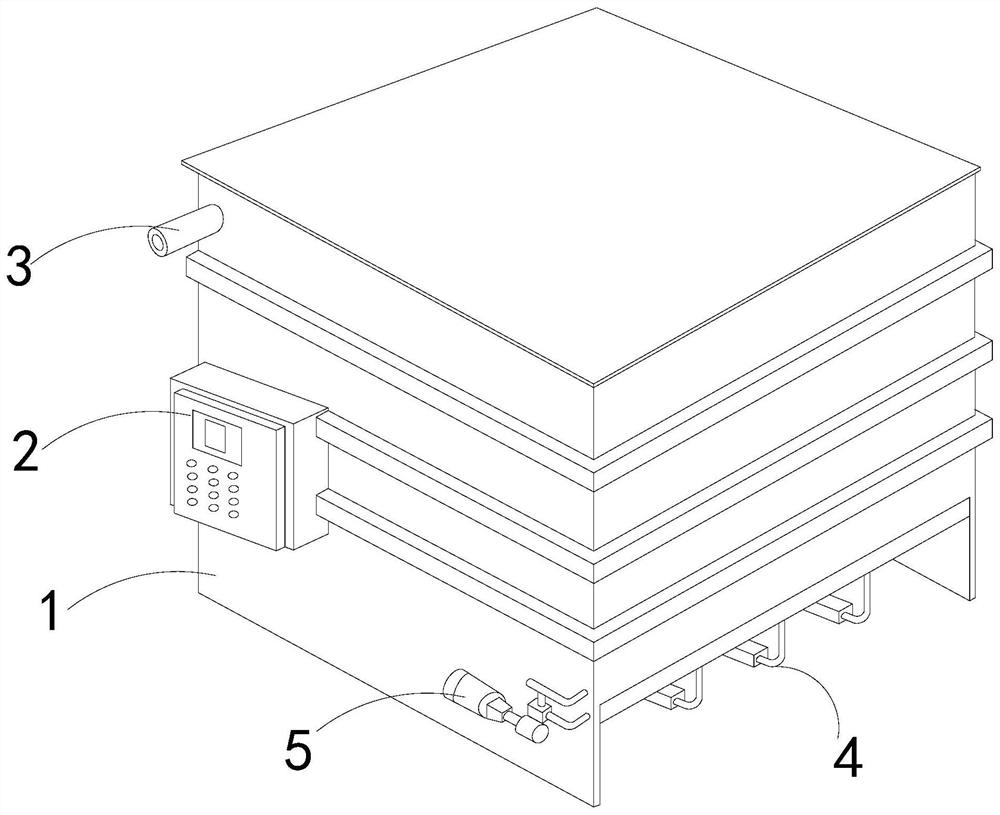

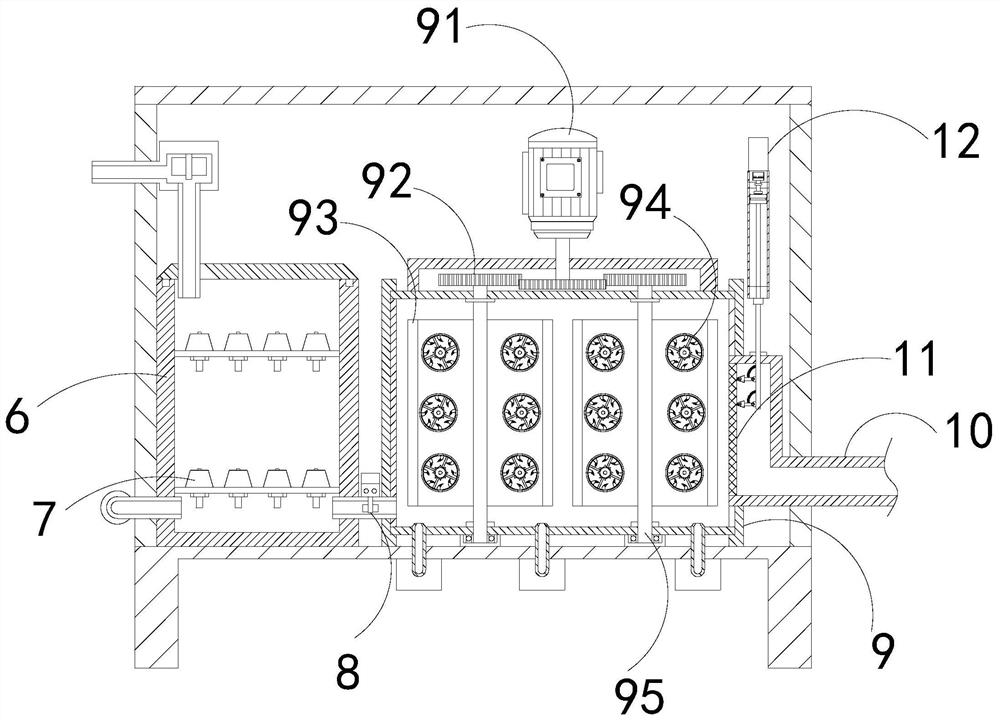

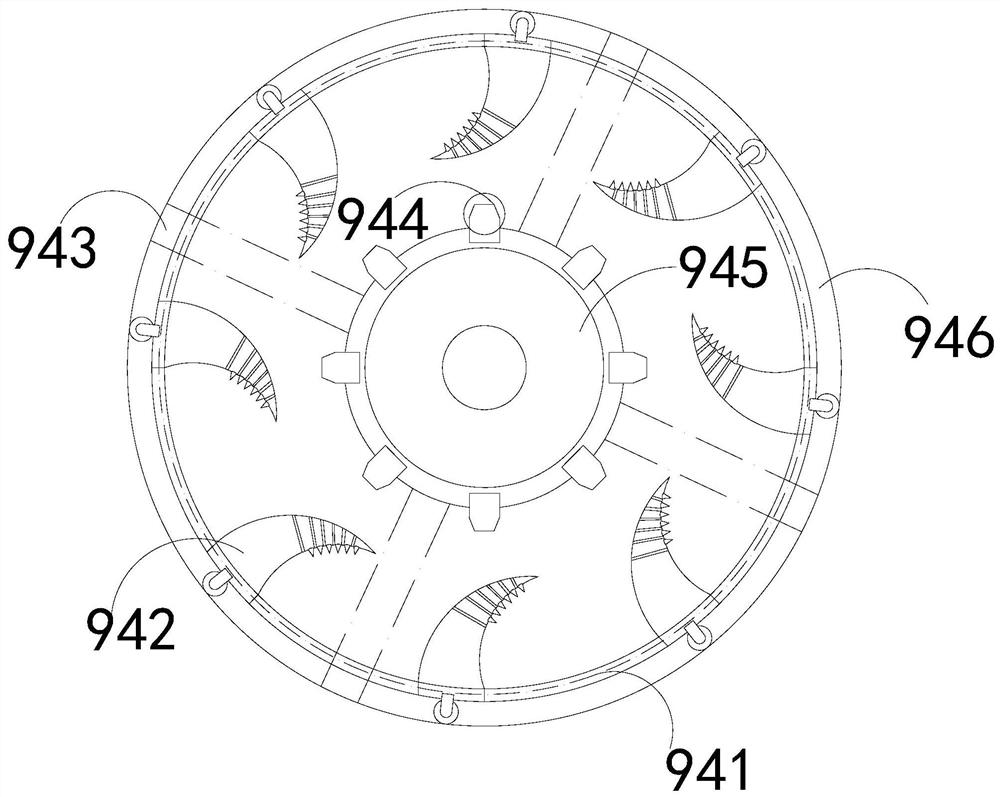

[0028] The invention discloses a device for collecting and filtering sanitary napkin bleaching waste water, which is equipped with a device shell 1, a console 2, a water inlet pipe 3, a secondary feed 4, a primary feed 5, a sedimentation tank 6, a filter 7, Water pump 8, mixing device 9, water outlet 10, filter screen 11, hole cleaning device 12, the right end of the console 2 is detachably connected to the left end of the equipment shell 1, and the water inlet pipe 3 is embedded and connected inside the equipment shell 1. The secondary feed 4 is threadedly connected to the bottom surface of the equipment shell 1, the front end of the primary feed 5 is detachably connected under the left end of the equipment shell 1, the settling bucket 6 is vertically connected to the left end of the equipment shell 1, and the filter 7 It is detachable inside the settling barrel 6, the right end of the settling barrel 6 is embedded a...

Embodiment 2

[0036] as attached Image 6 To attach Figure 7 Shown:

[0037] The invention discloses a device for collecting and filtering sanitary napkin bleaching wastewater. The hole cleaning device 12 includes a telescopic rod 121, a bearing block 122, a cleaning rod 123, and a special-shaped spring 124. The right end of the bearing block 122 is welded to the left end of the telescopic rod 121. The right end of the cleaning rod 123 is movably connected to the left end of the bearing block 122, and the outer wall of the cleaning rod 123 is movably connected to the right end of the telescopic rod 121 through a special-shaped spring 124. There are two cleaning rods 123 with the same structure. The front end of the cleaning rod 123 is The conical shape is fixedly connected to the left end of the telescopic rod 121 side by side, and the filter screen 11 can be cleaned to the greatest extent.

[0038] Wherein, the cleaning rod 123 is composed of a micro motor B1, a cam B2, a connecting spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com