Low-heat-generation rubber composition and preparation method thereof

A rubber composition and low heat generation technology, applied in the field of low heat generation rubber composition and its preparation, can solve problems such as tire tread delamination, temperature rise, and internal aging, so as to reduce rubber heat generation and ensure self- Viscosity, the effect of solving the high heat generation of rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

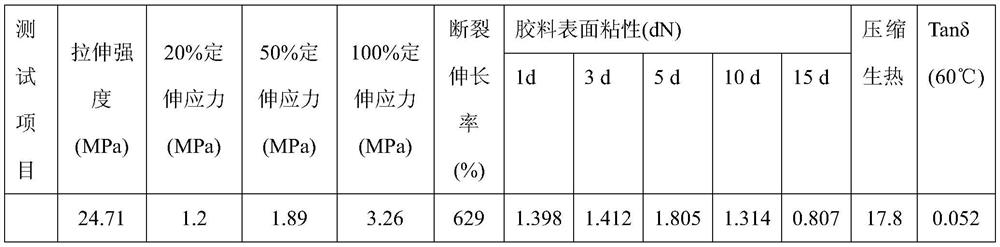

Embodiment 1

[0020] A low heat generation rubber composition comprising the following components by weight:

[0021] Natural rubber: 95-105 parts, carbon black: 32-36 parts, white carbon black: 12-18 parts, zinc oxide: 2-5 parts, stearic acid: 0.7-1.2 parts, antioxidant RD: 0.7-1.2 parts , antiaging agent 4020: 1.2~2 parts, tackifying resin: 2~5 parts, N-tert-butyl-α-benzothiazole: 1~1.6 parts, 1,3-diphenylguanidine: 0.1~0.3 parts, 4 , 4'-dithiodimorpholine: 0.6-1.2 parts, sulfur: 2.1-2.6 parts, methyl etherified hexamethylolmelamine resin: 1-5 parts.

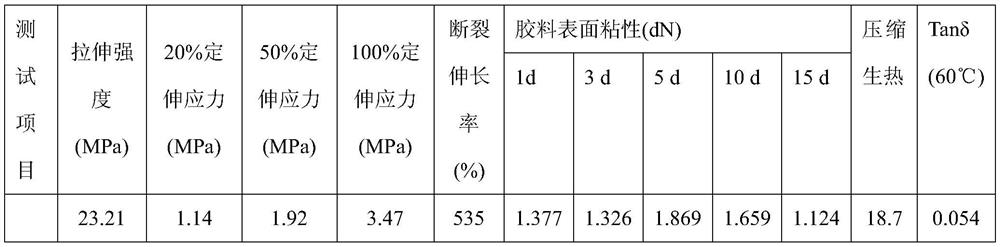

Embodiment 2

[0023] A low heat generation rubber composition comprising the following components by weight:

[0024] Natural rubber: 98-100 parts, carbon black: 33-35 parts, white carbon black: 15-16 parts, zinc oxide: 3-4 parts, stearic acid: 0.9-1.0 parts, antioxidant RD: 1.0-1.1 parts , Antiaging agent 4020: 1.5-1.6 parts, tackifying resin: 3-4 parts, N-tert-butyl-α-benzothiazole: 1.2-1.4 parts, 1,3-diphenylguanidine: 0.1-0.2 parts, 4 , 4'-dithiodimorpholine: 0.8-1.0 parts, sulfur: 2.3-2.4 parts, methyl etherified hexamethylolmelamine resin: 3-4.5 parts.

Embodiment 3

[0026] A low heat generation rubber composition comprising the following components by weight:

[0027] Natural rubber: 99 parts, carbon black: 34 parts, silica: 14 parts, zinc oxide: 4 parts, stearic acid: 1.1 parts, antioxidant RD: 0.9 parts, antioxidant 4020: 1.4 parts, tackifying resin: 3 parts, N-tert-butyl-α-benzothiazole: 1.3 parts, 1,3-diphenylguanidine: 0.2 parts, 4,4′-dithiodimorpholine: 0.9 parts, sulfur: 2.5 parts, formazan Etherified hexamethylolmelamine resin: 3.5 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com