Nylon fabric dyeing equipment

A technology for nylon fabrics and dyeing equipment, applied in the field of fabric processing, can solve the problems of increased cost, unfavorable production and use by manufacturers, shallow dyeing degree of nylon fabrics, etc., and achieves the effects of improving dyeing quality, dyeing efficiency, and dyeing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

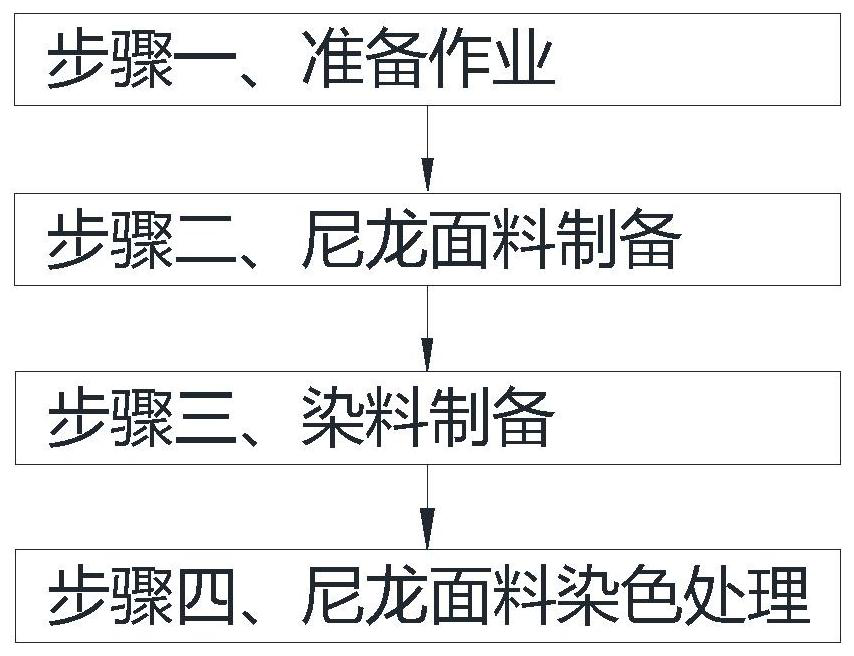

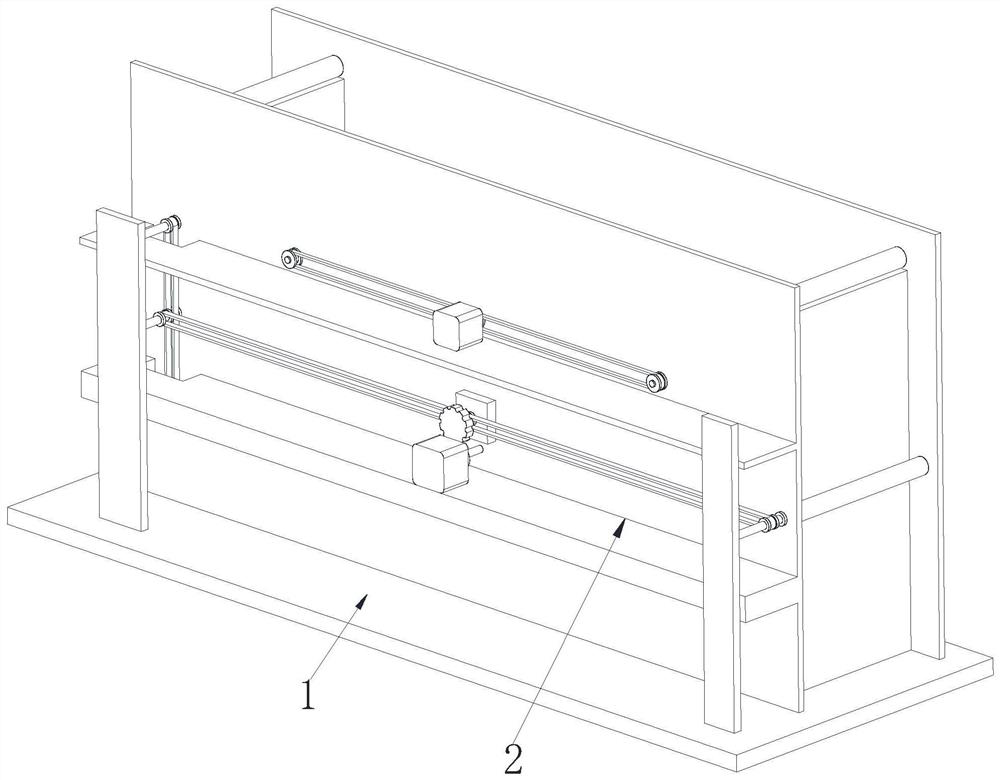

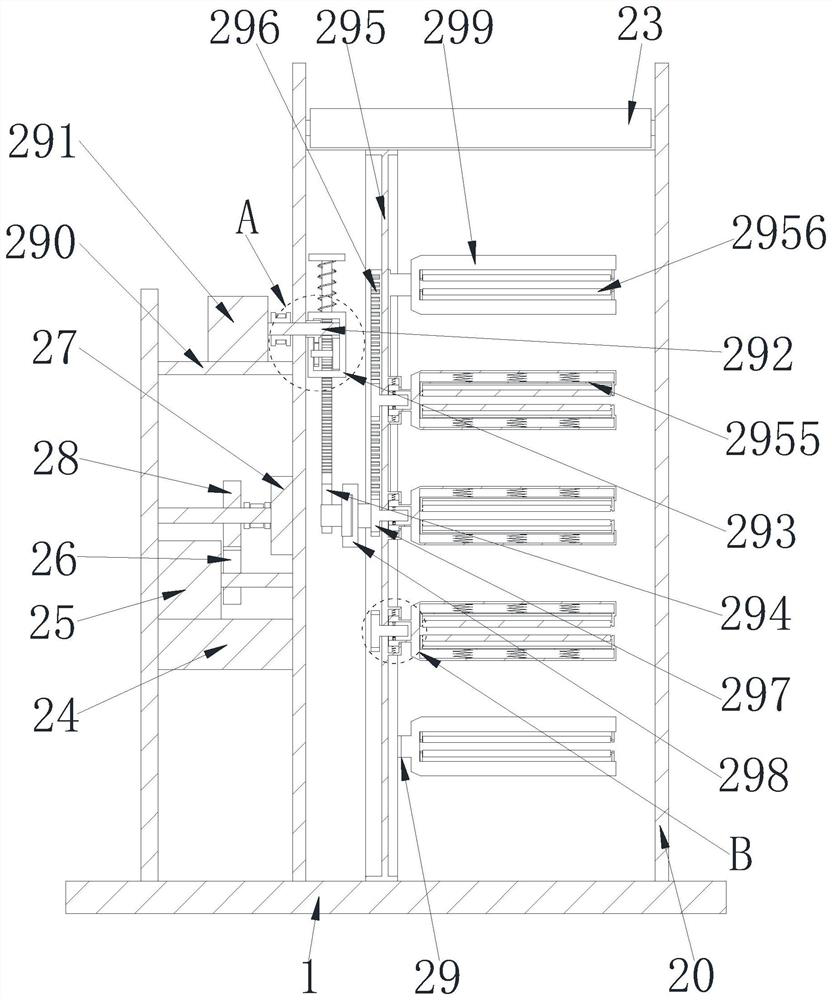

[0032] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 10 , to further elaborate the present invention.

[0033] A kind of nylon fabric dyeing process, it has used a kind of nylon fabric dyeing equipment, this nylon fabric dyeing equipment comprises base 1 and dyeing device 2, when adopting above-mentioned nylon fabric dyeing equipment to dye nylon fabric, specific method is as follows:

[0034] Step 1, preparatory work: debug the nylon fabric dyeing equipment of the present invention;

[0035] Step 2. Nylon fabric preparation: heating and melting the raw materials for making nylon fabrics and performing drawing treatment, and then using textile equipment to weave silk threads into nylon fabrics;

[0036] Step 3. Dye preparation: uniformly mix and stir the dyes for dyeing nylon fabrics through stirring equipment;

[0037]Step 4: Nylon fabric dyeing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com