Durable mosquito-repellent fabric and preparation method thereof

A kind of fabric and long-lasting technology, applied in the direction of dyeing, plant fiber, fiber treatment, etc., can solve the problem of mosquito repellent fabrics that cannot be repelled for a long time, and achieve the effect of good mosquito repellent effect, comfortable wearing and human body safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]A sustainable mosquito repellent fabric, the fabric in this embodiment is obtained by the following steps:

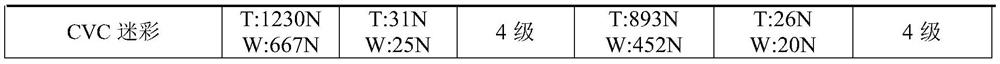

[0031](1) Burning: Take the CVC camoufled specification of 20 * 16 / 120 * 60 * 63, remove the surface of the fabric, get the burning wool;

[0032](2) Pulling: Through the baked fabric so that the woolen fabric is dipped in the manner, it is more than 100 ° C to fade at 60 min, and the drift is drifted; during the process of drifting the working fluid, the vehicle speed is 60m. / min, the liquid rate is 85%; the drifting process includes the following concentrations of components: basic protease 2709 10 g / l, soap 5g / L, sodium hydroxide 5g / L and hydrogen peroxide 7 g / L;

[0033](3) Wire: The pulverization concentration of the pulverized rumored concentration of 180 to 220 g / L is 10s, and then the dehydrated to the fine base washed at 75 to 80 ° C, and then rinsed with 90 ~ 95 ° C. The pH of the fabric fabric surface is 7.0 ~ 8.5, and the wire treatment is completed.

[0034...

Embodiment 2

[0042]A sustainable mosquito repellent fabric, the fabric in this embodiment is obtained by the following steps:

[0043](1) Burning: Take the CVC camoufled specification of 20 * 16 / 120 * 60 * 63, remove the surface of the fabric, get the burning wool;

[0044](2) Pole: Those skilled rolling is pulled by the baked fabric, and then the steam of 70 minutes at 90 ° C, and the drift will be practiced; during the process of improving the drifting working fluid, the speed is 65m. / min, the liquid rate is 80%; the drifting process includes the following concentrations: neutral protease ZS724 12g / L, Rambon A 6g / L, sodium hydroxide 3g / L and hydrogen peroxide 6g / L;

[0045](3) Wire: The pulverization concentration of the pulverized rumored concentration of 180 to 220 g / L is 10s, and then the dehydrated to the fine base washed at 75 to 80 ° C, and then rinsed with 90 ~ 95 ° C. The pH of the fabric cloth is 7.0 ~ 8.5, and the wire treatment is completed.

[0046](4) Type: Type a wire-based fabri...

Embodiment 3

[0054]A sustainable mosquito repellent fabric, the fabric in this embodiment is obtained by the following steps:

[0055](1) Burning: Take the CVC camoufled specification of 20 * 16 / 120 * 60 * 63, remove the surface of the fabric, get the burning wool;

[0056](2) Pulling: Burning the woolen fabric to extract the drifting working fluid by dipping, and then fossast the steam of 55 min at 100 ° C, to practice the drift; the speed of 60 m / min, the liquid rate is 90%; The drifting process includes the following concentrations of components: cellulase 10g / L, laundry powder 6g / L, sodium hydroxide 8 g / L and hydrogen peroxide 7 g / L;

[0057](3) Wire: The pulverization concentration of the pulverized rumored concentration of 180 to 220 g / L is 10s, and then the dehydrated to the fine base washed at 75 to 80 ° C, and then rinsed with 90 ~ 95 ° C. The pH of the fabric cloth is 7.0 ~ 8.5, and the wire treatment is completed.

[0058](4) Type: Type a wire fabric at a speed of 85 m / min at 200 ° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com