Exhaust pipe decorative cover

A technology for decorative covers and exhaust pipes, which is applied in the direction of exhaust devices, noise reduction devices, engine components, etc., and can solve problems such as long flanges of electroplated frames, insufficient strength, increased area of electroplated parts, and related product costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

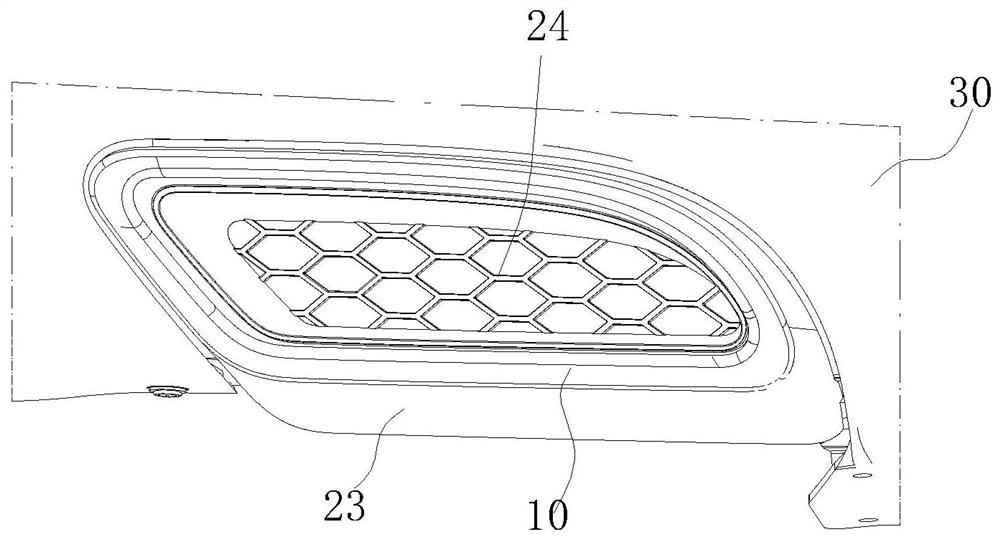

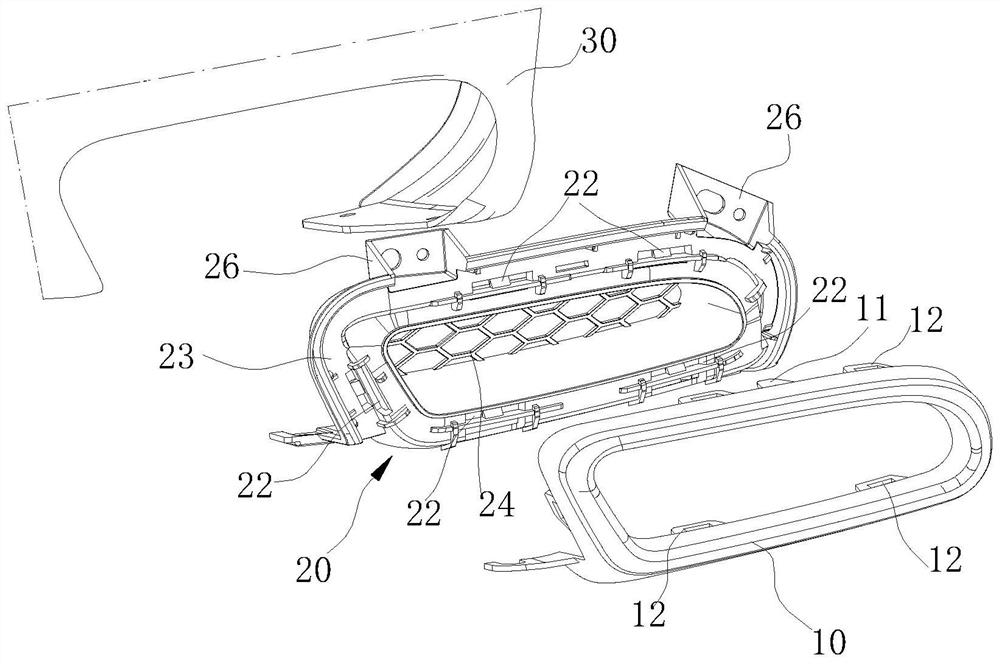

[0016] For the convenience of explanation, the following problems are first defined: the direction of vehicle length is X direction, the direction of vehicle width is direction Y, and the direction of vehicle height is Z direction. The exhaust pipe decoration cover is installed at the rear of the car for the purpose of left-right symmetry and beauty. A fake trim cover where the exhaust pipes would be.

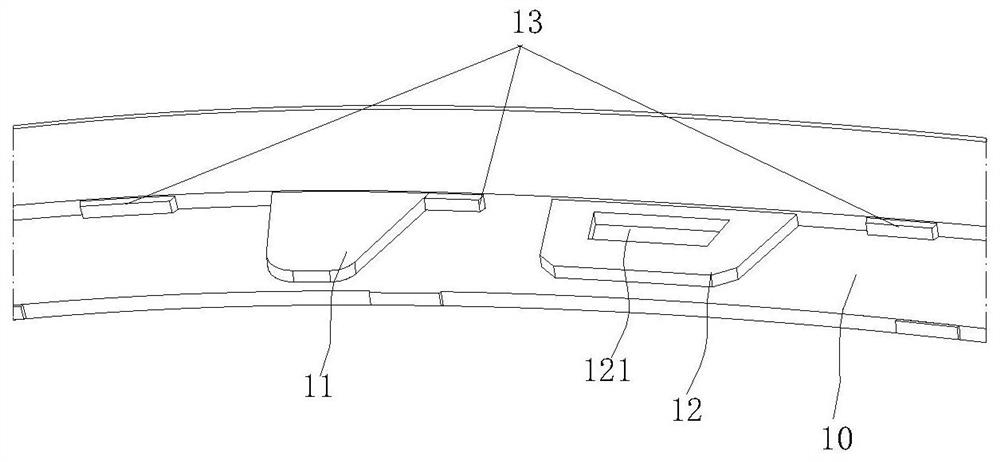

[0017] An exhaust pipe decorative cover, comprising an outer frame 10 and an inner panel 20, a Y-direction positioning tongue 11 and a snap-in piece 12 protrude from the edge of the outer frame 10 toward the inner panel 20, and the Y-direction positioning tongue 11 It is inserted into the positioning hole 21 provided on the inner plate 20 to form a Y-direction positioning fit. The snap-in piece 12 is provided with a square hole 121, and the inner plate 20 is provided with a snap-in body 22 at a position corresponding to the snap-in piece 12. The connecting body 22 is engaged wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com