Self-synchronizing vibration exciter for forced thin oil lubrication

A technology of thin oil lubrication and self-synchronization, which is applied in the direction of lubricating parts, engine lubrication, and fluid using vibration, etc. It can solve problems such as bearing burnout, reducing the service life of the exciter, and burnout of the exciter bearing. Achieve the effects of avoiding bearing wear and burnout, improving operational reliability, and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

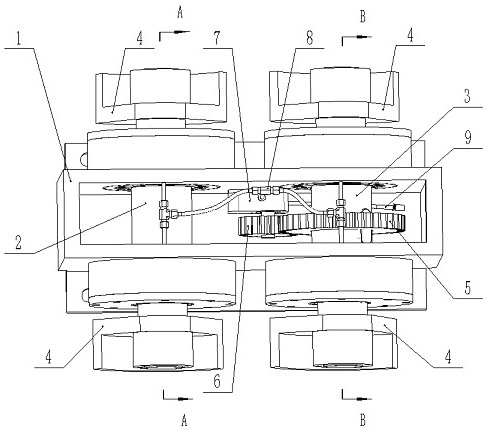

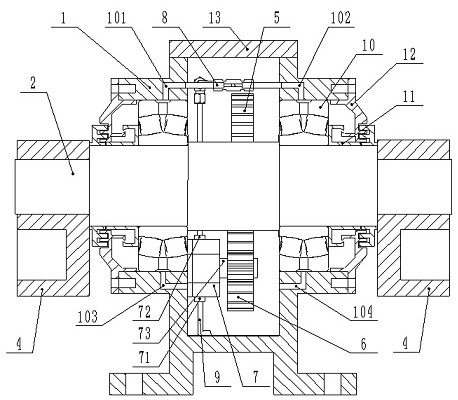

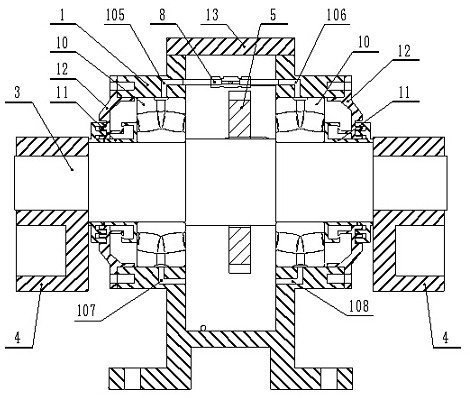

[0014] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a self-synchronous vibrator for forced thin oil lubrication is characterized in that it includes a box body 1, a box cover 13, a high-position transmission shaft 2, a low-position transmission shaft 3, a bearing 10, a sealing ring 11, an end cover 12, Eccentric block 4, driving gear 5, driven gear 6, oil pump 7, oil inlet pipe 9 and oil discharge pipe 8; among them, the two ends of the high-position transmission shaft 2 and the low-position transmission shaft 3 are respectively supported by bearings 10 in the mounting holes of the box body 1 In the middle, and through the sealing ring 11 and the end cover 12 to seal the extension side of the high transmission shaft 2 and the low transmission shaft 3; the four eccentric blocks 4 are fixedly connected to the two ends of the high transmission shaft 2 and the low transmission shaft 3 respectively On the extension journal; the oil pump 7 is fixed on the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com