High-peak-power single-frequency narrow-linewidth nanosecond triangular short-pulse fiber laser

A technology of fiber lasers and pulsed lasers, which is applied to lasers, laser components, phonon exciters, etc., can solve the problems that lasers cannot achieve the desired effect, and achieve industrialized mass production, small optical path loss, and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

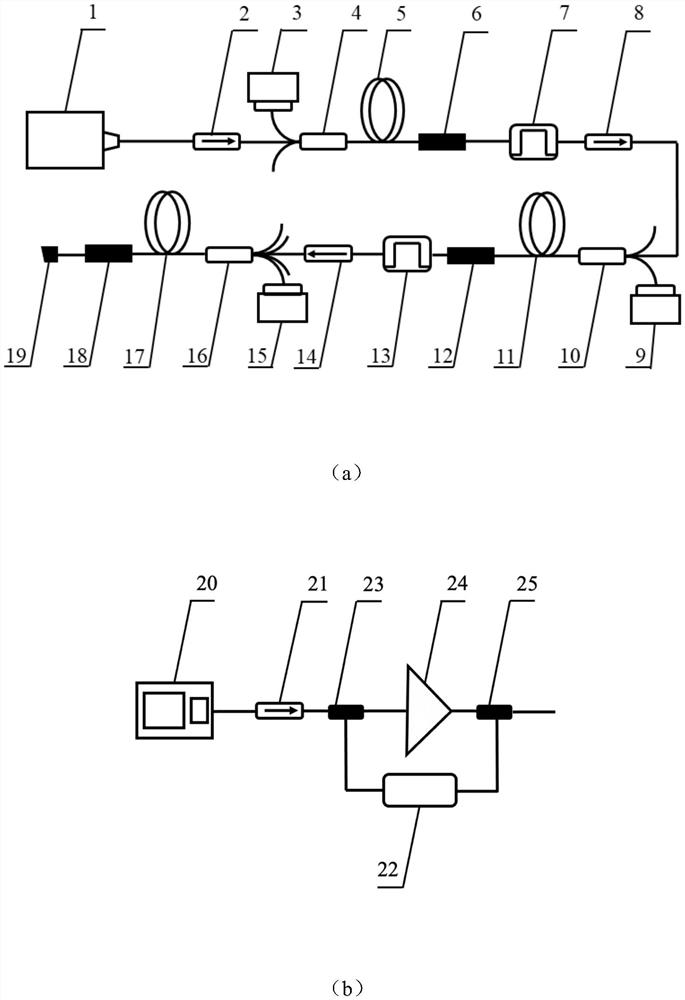

[0050] A high-peak-power single-frequency narrow-linewidth triangular nanosecond short-pulse fiber laser adopts a MOPA structure with two-stage power pre-amplification and one-stage power main amplifier stage. For its implementation, see figure 1 (a), comprising: a pulsed laser seed source 1, a first isolator 2, a first pumping source 3, a first beam combiner 4, a first double-clad active optical fiber 5, and a first cladding optical stripper 6 , the first bandpass filter 7, the second isolator 8, the second pumping source 9, the second beam combiner 10, the second double-clad active fiber 11, the second cladding optical isolator 12, the second Bandpass filter 13, third isolator 14, third pumping source 15, third beam combiner 16, third double-clad active optical fiber 17, third cladding optical stripper 18, collimator outputter 19 .

[0051] Wherein, the first pump source 3, the first beam combiner 4, the first double-clad active optical fiber 5, the first cladding optical s...

Embodiment 2

[0065] A high peak power single-frequency narrow-linewidth triangular nanosecond short-pulse fiber laser, using a MOPA structure with two-stage power pre-amplification and one-stage power main amplification, see figure 1 (a), comprising: a pulsed laser seed source 1, a first isolator 2, a first pumping source 3, a first beam combiner 4, a first double-clad active optical fiber 5, and a first cladding optical stripper 6 , the first bandpass filter 7, the second isolator 8, the second pumping source 9, the second beam combiner 10, the second double-clad active fiber 11, the second cladding optical isolator 12, the second Bandpass filter 13, third isolator 14, third pumping source 15, third beam combiner 16, third double-clad active optical fiber 17, third cladding optical stripper 18, collimator outputter 19 .

[0066] Wherein, the first pump source 3, the first beam combiner 4, the first double-clad active optical fiber 5, the first cladding optical stripper 6, the first bandp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com