Lactose-free micro-fermented cow milk and preparation method thereof

A technology of micro-fermentation and milk, which is applied in the direction of dairy products, milk preparations, applications, etc., and can solve problems such as products that cannot satisfy consumers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a method for preparing lactose-free slightly fermented milk, the preparation method comprising the following steps:

[0029] S1: preheating the raw milk and skimming to obtain skim milk and cream;

[0030] S2: Sterilize the skim milk in S1, add yeast and lactase, heat, then add Lactobacillus plantarum, carry out fermentation and hydrolysis, and obtain a fermentation and hydrolysis feed liquid;

[0031] S3: Sterilize the cream in S1, add it to the fermented hydrolyzed feed liquid in S2, preheat, aseptically homogenize, and then cool and fill.

[0032] Specifically, in the S1, the raw milk is subjected to fat separation, and the fat content in the obtained skim milk is lower than 0.5%; the raw milk is preheated to 60-65°C.

[0033] In said S2, the sterilization temperature of the skim milk is 90-95° C., and the sterilization time is 3-7 minutes.

[0034] In the S2, the fermentation temperature is 25-30° C., the fermentation time is 8-...

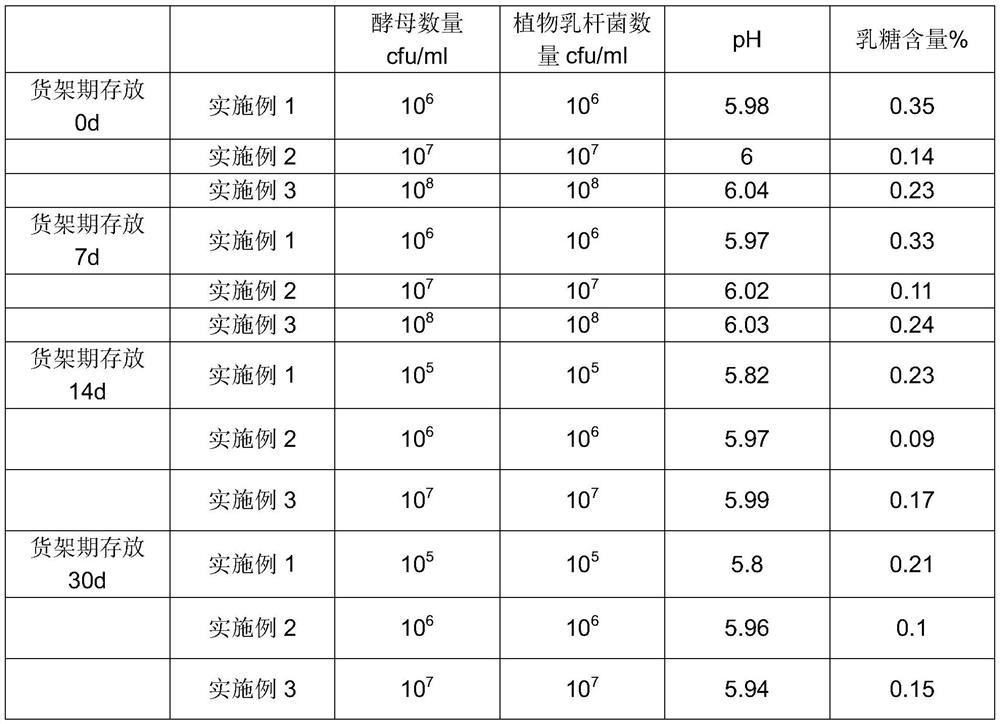

Embodiment 1

[0045] (1) Preheat raw milk (99.971% added) to 60°C to separate fat to obtain skim milk and cream, the fat content in skim milk is <0.5%;

[0046] (2) The skim milk and cream obtained in step (1) are sterilized separately, the sterilization condition of skim milk is 90°C / 3min, and the sterilization condition of cream is 108°C / 30s. After sterilization, the cream is cooled to 10°C for use. After sterilization, the skim milk was cooled to 25°C (pH 6.7), added yeast starter 0.008% and lactase 0.02% to ferment for 12 hours, and the pH of the milk was 6.38; after the yeast was fermented, the milk was cooled to 35°C, inoculated with 0.001% Lactobacillus plantarum and continued to ferment for 4 hours , the pH reaches 5.98 to stop the fermentation;

[0047] (3) In step (2), the milk and cream fermented by Lactobacillus plantarum were preheated to 40°C and then mixed, and homogenized at this temperature with a homogenization pressure of 150 bar, cooled and then filled.

[0048] In the...

Embodiment 2

[0050] (1) Preheat raw milk (99.925% added) to 62°C to separate fat to obtain skim milk and cream, the fat content in skim milk is <0.5%;

[0051](2) The skim milk and cream obtained in step (1) are sterilized separately, the sterilization condition of skim milk is 93°C / 5min, and the sterilization condition of cream is 110°C / 25s. After sterilization, the cream is cooled to 10°C for use. After sterilization, the skim milk was cooled to 30°C (pH 6.7), added with 0.012% yeast starter and 0.06% lactase to ferment for 8 hours, and the pH of the milk was 6.43; after heating up the yeast fermented milk to 37°C, inoculated with 0.003% Lactobacillus plantarum and continued to ferment for 3 hours , the pH reaches 6 to stop the fermentation;

[0052] (3) In step (2), the milk fermented by Lactobacillus plantarum and the sterilized cream are preheated to 45°C and then mixed, and homogenized at this temperature. The homogenization pressure is 200 bar. Can.

[0053] Lactose content is 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com