Filtering device for producing special rice fertilizer

A filter device and special fertilizer technology, which is applied in the direction of filtration separation, filter circuit, mobile filter element filter, etc., can solve the problems of high vibration frequency of vibration motor, failure of special fertilizer to filter, and damage to solid particles, etc., to achieve improved filtration Speed, improved functionality, improved filtering effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

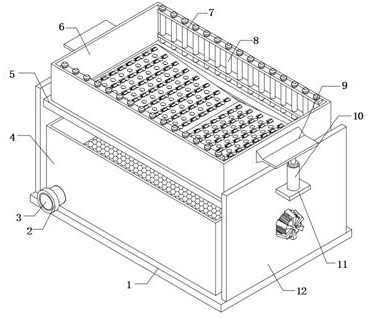

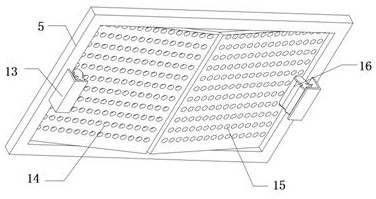

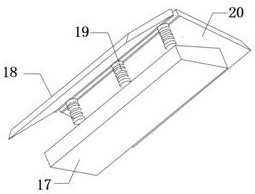

[0031] refer to Figure 1-4 , a filter device for special rice fertilizer production, comprising a base plate 1 and a fixed frame 5, one side inner wall of the fixed frame 5 is hinged to a No. 1 filter screen 14, and the other side inner wall of the fixed frame 5 is hinged to a No. Filter screen 15, the No. 1 filter screen 14 and the No. 2 filter screen 15 are connected by hinges, the junction of the No. 1 filter screen 14 and the No. 2 filter screen 15 is made of deformable elastic material, the No. 1 filter screen 14 and the No. 2 filter screen The top outer wall of the net 15 is fixedly connected with connecting blocks 17 at equal distances, and the connecting blocks 17 are positioned between every two filter holes, and the top outer walls of the connecting blocks 17 are fixedly connected with reciprocating springs 19 equidistantly, and the tops of multiple reciprocating springs 19 The two ends of the outer wall are respectively fixedly connected with the No. 1 buffer plate...

Embodiment 2

[0042] refer to Figure 1-5 , a filter device for special rice fertilizer production, comprising a base plate 1 and a fixed frame 5, one side inner wall of the fixed frame 5 is hinged to a No. 1 filter screen 14, and the other side inner wall of the fixed frame 5 is hinged to a No. Filter screen 15, the No. 1 filter screen 14 and the No. 2 filter screen 15 are connected by hinges, the junction of the No. 1 filter screen 14 and the No. 2 filter screen 15 is made of deformable elastic material, the No. 1 filter screen 14 and the No. 2 filter screen The top outer wall of the net 15 is fixedly connected with connecting blocks 17 at equal distances, and the connecting blocks 17 are positioned between every two filter holes, and the top outer walls of the connecting blocks 17 are fixedly connected with reciprocating springs 19 equidistantly, and the tops of multiple reciprocating springs 19 The two ends of the outer wall are respectively fixedly connected with the No. 1 buffer plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com