Dry-method sand making process using roller press

A technology using rollers and presses, which is applied in the field of dry sand making technology, can solve problems such as poor particle shape, and achieve the effect of increasing the amount of sand making and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

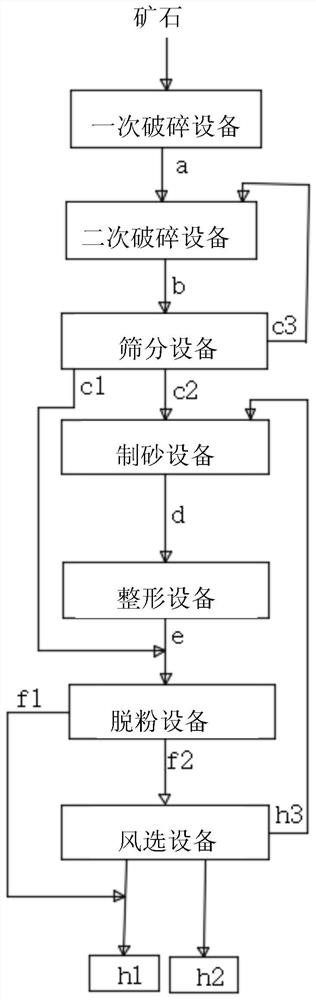

[0026] Example: as attached figure 1 As shown, a dry sand making process using a roller press includes the following steps:

[0027] Step 1, the first crushing process: the ore is crushed by primary crushing equipment, and the primary crushing equipment is one or more of gyratory crushers, jaw crushers, impact crushers, and hammer crushers to obtain Product a after crushing, the diameter of product a is less than 180mm;

[0028] Step 2, the second crushing process: the product a obtained in step 1 is crushed by secondary crushing equipment, and the secondary crushing equipment is one of single cylinder cone crusher, impact crusher, hammer crusher or Various, to obtain the product b after the second crushing, the diameter of the product b is less than 50mm;

[0029] Step 3, the first screening process: the product b obtained in step 2 is screened through a primary screening device to obtain product c3 located in the upper layer of the primary screening device, product c2 in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com