Online cutting, marking, detecting and packaging automatic production line for laser machining of two-dimensional codes

An automated production line and laser processing technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of harmful smoke, melting and deformation of packaging bags, etc., to reduce absorption, reduce melting and deformation, and improve the degree of safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

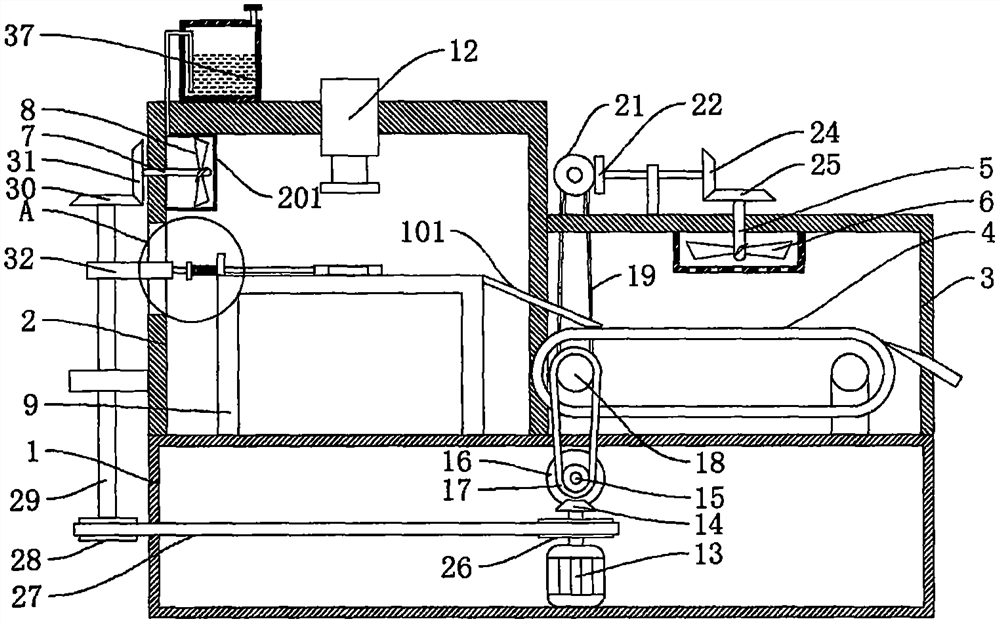

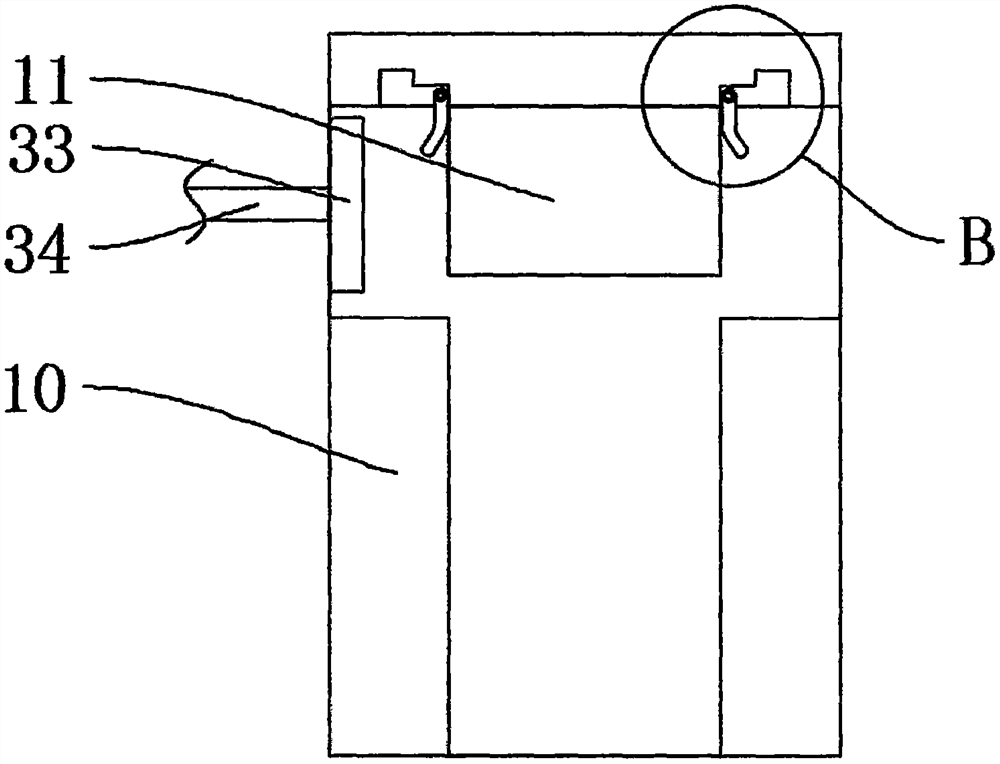

[0032] refer to figure 1 , figure 2 , image 3 , Figure 5 , Image 6, an automatic laser processing two-dimensional code online cutting, marking, testing and packaging production line, including a base 1, a workpiece 11, a coding mechanism and a transmission mechanism, the coding mechanism and the transmission mechanism are fixedly connected to the base 1, and the base 1 The support frame 2 is fixedly connected, the support frame 2 is rotatably connected with a second rotating rod 7, the second rotating rod 7 is fixedly connected with a suction fan 8, the base 1 is fixedly connected with an auxiliary frame 3, and the auxiliary frame 3 is rotatably connected with a The first rotating rod 5 is fixedly connected with a cooling fan 6 , and the base 1 is fixedly connected with a driving mechanism, and the driving mechanism is connected with the transmission mechanism in rotation.

[0033] The coding mechanism includes a workbench 9, a code base 10 and a laser coder 12, the la...

Embodiment 2

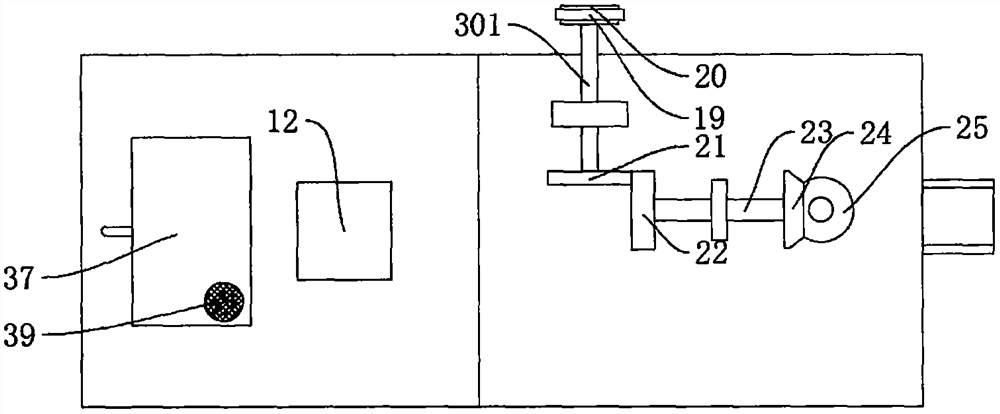

[0044] refer to Figure 4 , an automatic laser processing two-dimensional code online cutting, marking, testing and packaging production line, including a base 1, a workpiece 11, a coding mechanism and a transmission mechanism, the coding mechanism and the transmission mechanism are fixedly connected to the base 1, and the base 1 The support frame 2 is fixedly connected, the support frame 2 is rotatably connected with a second rotating rod 7, the second rotating rod 7 is fixedly connected with a suction fan 8, the base 1 is fixedly connected with an auxiliary frame 3, and the auxiliary frame 3 is rotatably connected with a The first rotating rod 5 is fixedly connected with a cooling fan 6 , and the base 1 is fixedly connected with a driving mechanism, and the driving mechanism is connected with the transmission mechanism in rotation.

[0045] The coding mechanism includes a workbench 9, a code base 10 and a laser coder 12, the laser coder 12 is fixedly connected to the support...

Embodiment 3

[0056] refer to Figure 1-7 , an automatic laser processing two-dimensional code online cutting, marking, testing and packaging production line, including a base 1, a workpiece 11, a coding mechanism and a transmission mechanism, the coding mechanism and the transmission mechanism are fixedly connected to the base 1, and the base 1 The support frame 2 is fixedly connected, the support frame 2 is rotatably connected with a second rotating rod 7, the second rotating rod 7 is fixedly connected with a suction fan 8, the base 1 is fixedly connected with an auxiliary frame 3, and the auxiliary frame 3 is rotatably connected with a The first rotating rod 5 is fixedly connected with a cooling fan 6 , and the base 1 is fixedly connected with a driving mechanism, and the driving mechanism is connected with the transmission mechanism in rotation.

[0057] The coding mechanism includes a workbench 9, a code base 10 and a laser coder 12, the laser coder 12 is fixedly connected to the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com