Battery pole piece forming processing equipment and processing method

A battery pole piece, forming and processing technology, which is applied to battery electrodes, other manufacturing equipment/tools, circuits, etc., can solve the problems of unsuitable battery pole piece mass production, large labor workload, and insufficient processing accuracy. Improve the efficiency of production and molding, improve the efficiency of placement, and improve the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

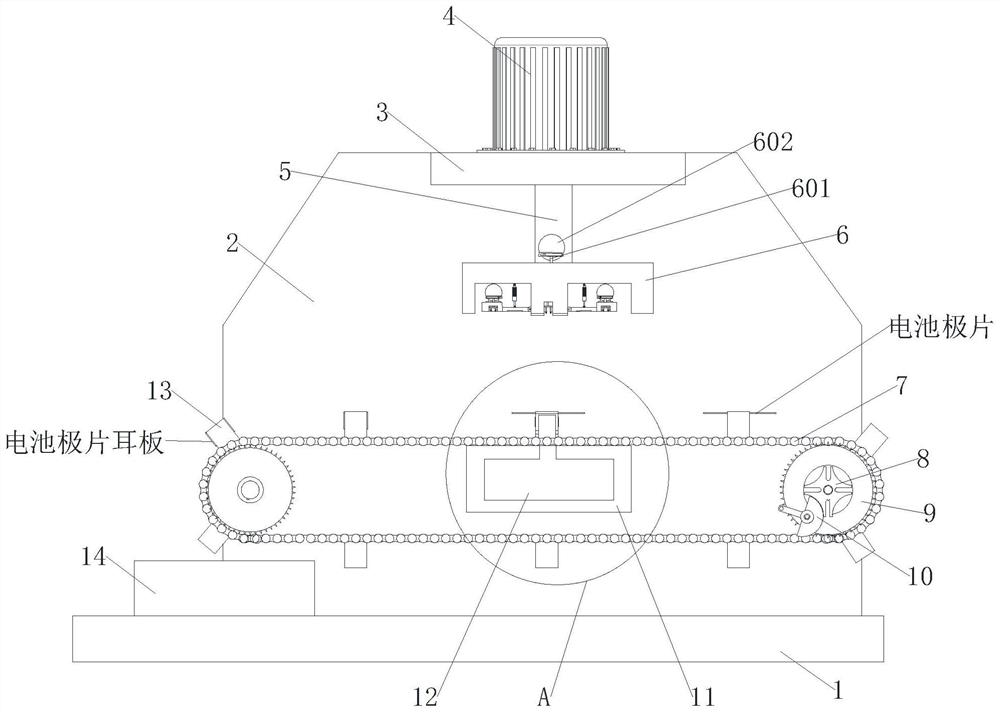

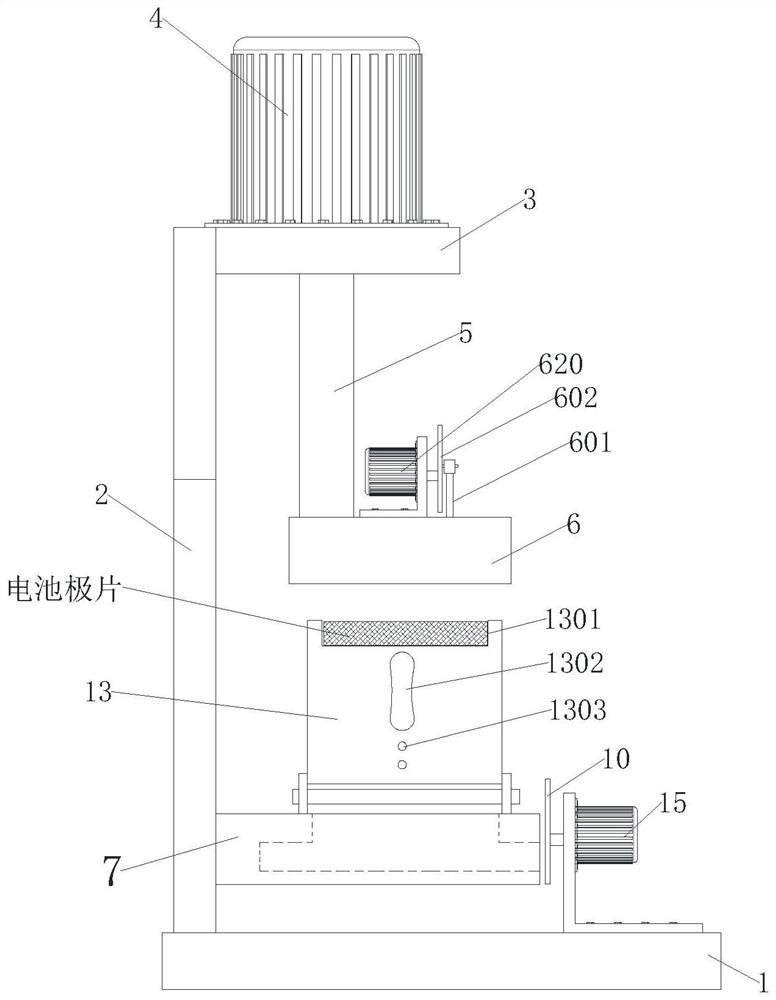

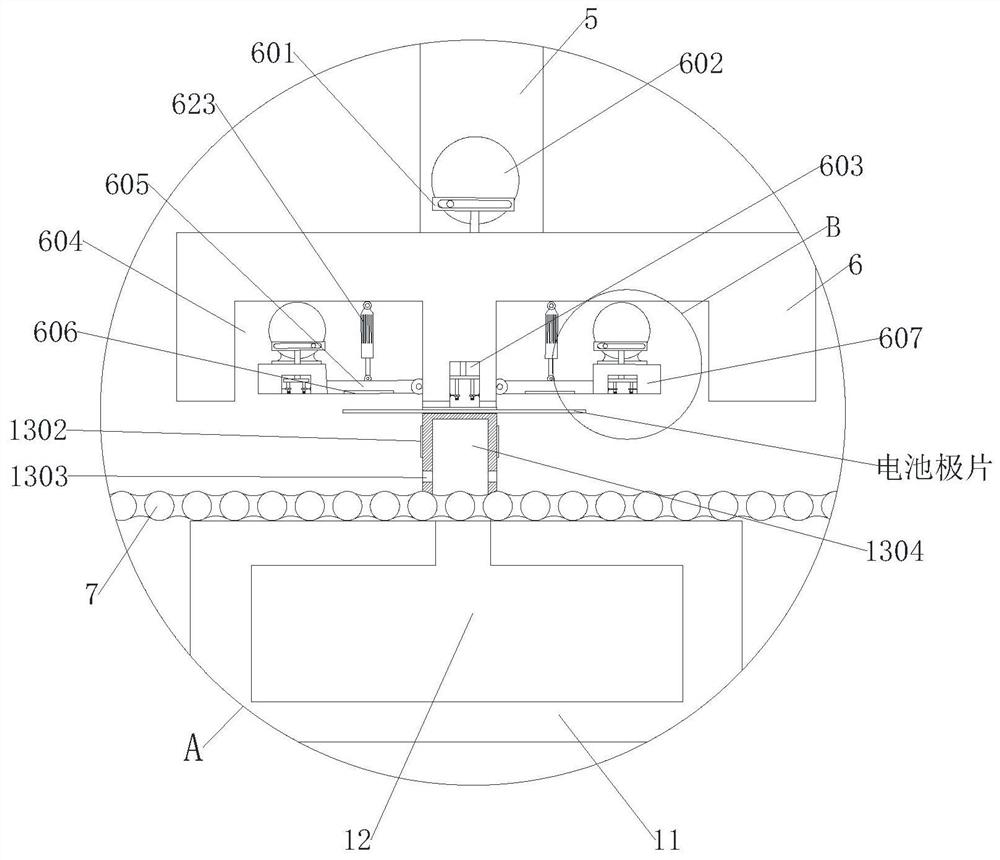

[0054] see Figure 1-11 , which is a schematic diagram of the overall structure of a battery pole piece forming processing equipment and processing method;

[0055] A battery pole piece forming and processing equipment, comprising a base 1 fixed horizontally on the ground, a side support frame 2 standing upright on the top of the base 1 is fixedly installed on the top of the base 1, and a top support placed horizontally is fixed on the top of the side support frame 2 Plate 3, an electric push rod 4 is fixedly installed on the top of the top support plate 3, a push rod 5 protrudes downward from the electric push rod 4, and a pressing block 6 is fixedly installed on the bottom end of the push rod 5;

[0056] The top of the base 1 is provided with a circularly rotating conveyor belt 7, the conveyor belt 7 is located on the front side of the side support frame 2 at the top of the base 1, and the two ends of the inner ring of the conveyor belt 7 are respectively provided with rolle...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap