Through channel floor device

A through-channel and floor technology, applied in the field of through-channel floor devices, can solve the problems of inability to adapt to low-floor models and high height, and achieve the effects of simple structure, lower overall height, and satisfaction of use requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

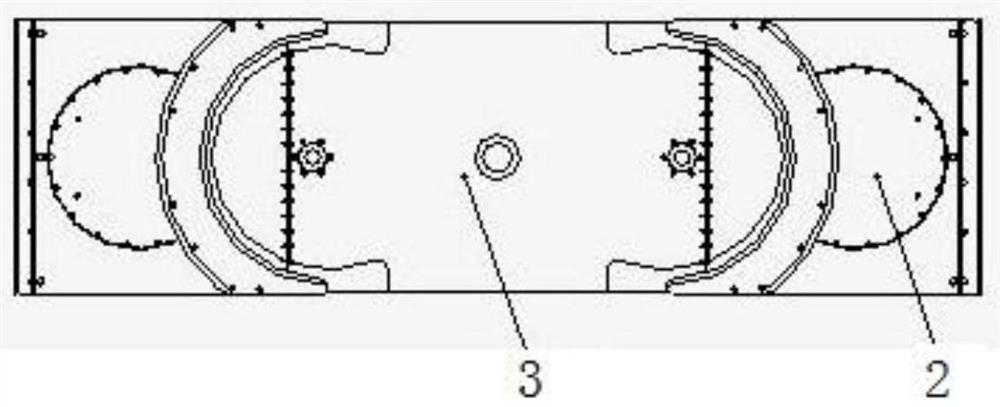

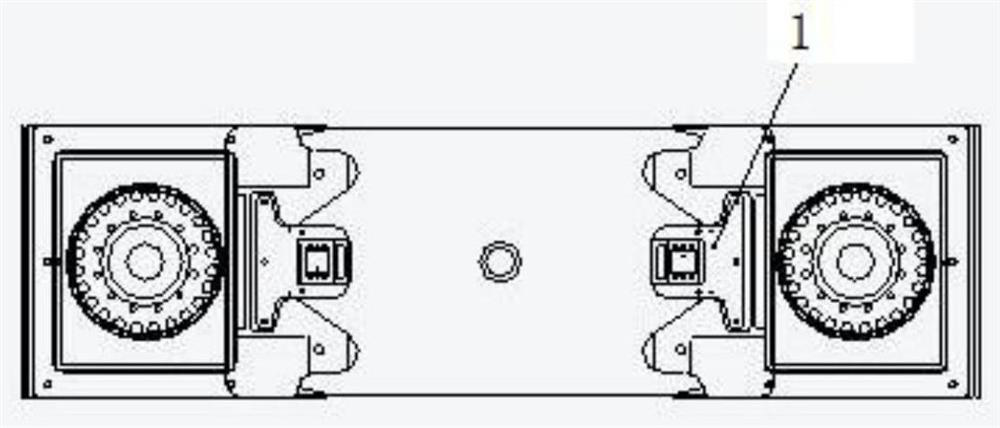

[0023]The main structure of the through-passage floor device involved in this embodiment includes a floor support component 1, a corridor floor component 2, and a transition plate component 3; two floor support components 1 are mirror-symmetrically arranged, and the floor support component 1 is provided with a corridor floor component 2, The corridor floor composition 2 is provided with a crossing board composition 3, and the two ends of the crossing board composition 3 are respectively lapped on the corridor floor composition 2; the main structure of the floor support composition 1 includes a base plate 4, a No. 1 flat washer 5, and a No. 1 screw 6. Wear plate 7, wear gasket 8, top bushing 9, washer 10, bearing backing plate 11, No. 2 screw 12, sealing strip 13, angular contact spherical sliding bearing 14, spherical bearing 15, No. 2 flat washer 16 , slotted nut 17, cotter pin 18, bearing cover plate 19, O-ring 20, No. 3 screw 21, buffer bracket 22 and buffer rubber strip 23;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com