Bearing device and special automobile assembly line

A bearing device and wheel technology, applied in the direction of wheels, motor vehicles, vehicle parts, etc., can solve the problems of difficulty, non-adjustable height, inconvenient operation, etc., and achieve the effect of good stability, high carrying capacity and convenient operation

Inactive Publication Date: 2021-04-09

NANJING UNIV OF SCI & TECH +1

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] 1. In order to meet the requirements of high load-carrying capacity, the height of the carrying device is mostly fixed, the height is not adjustable, and there is no lifting function, so it cannot be generally adapted to the assembly of vehicles of different heights;

[0006] 2. At present, the carrying device used in the special automobile assembly line is often designed as a fixed structure in order to meet the high-strength carrying requirements. When the car lands and needs to be removed from the carrying device, the operation is inconvenient and difficult.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

[0050] This embodiment discloses a special automobile assembly production line, which is provided with the carrying device described in Embodiment 1. Other equipment in the production line can be used as existing equipment, and will not be described in detail here. By adopting the carrying device described in Embodiment 1 The device can greatly reduce labor intensity and improve labor efficiency and safety.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

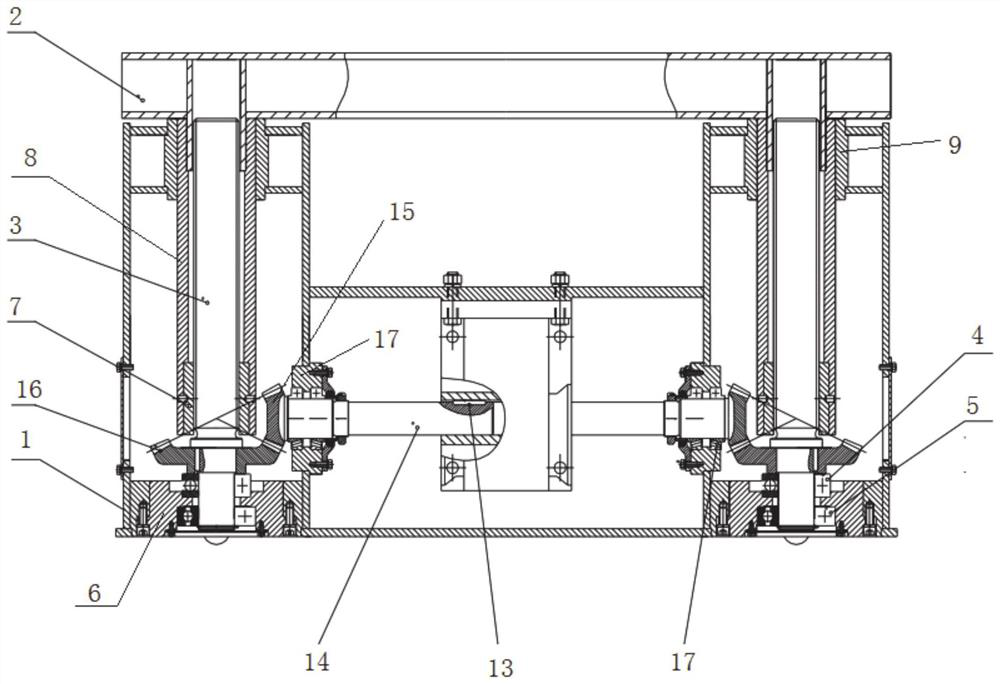

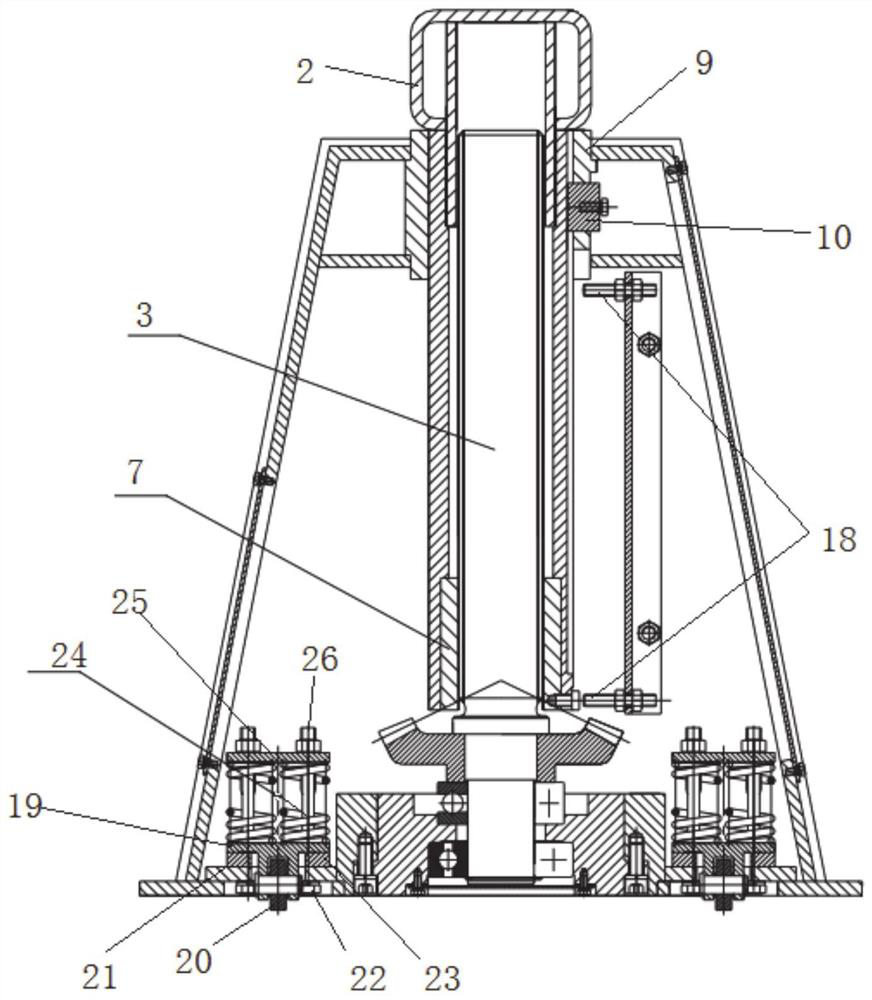

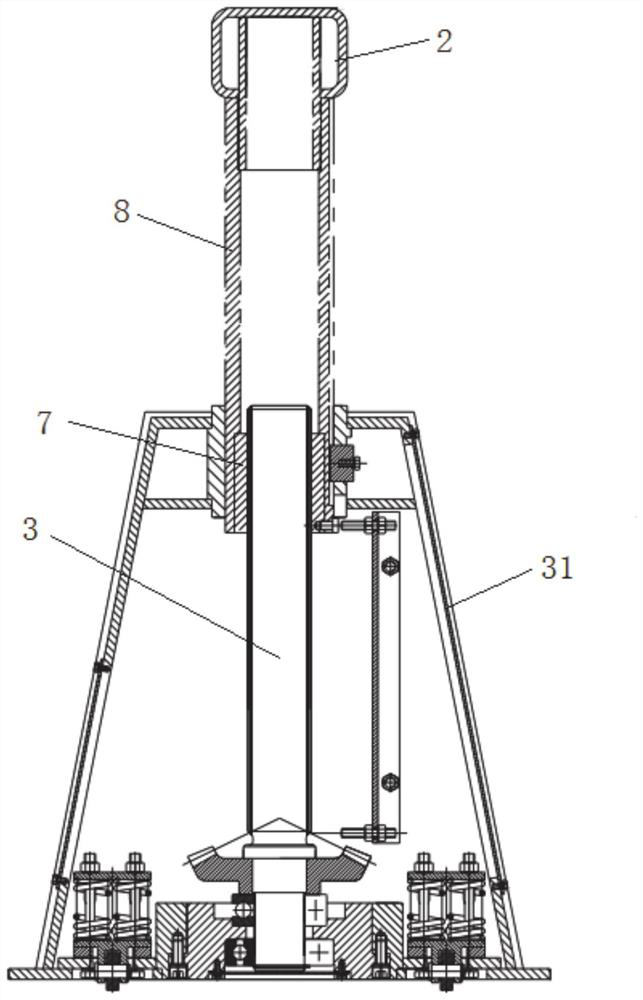

The invention relates to a bearing device and a special automobile assembly line. The bearing device comprises a shell, a first lifting mechanism and a second lifting mechanism are fixed in the shell, a plurality of wheel assemblies are further arranged at the bottom of the shell, each wheel assembly comprises a fixing frame, the bottom of each fixing frame is rotationally connected with a wheel, and a base plate is arranged between each fixing frame and the shell; the base plate is fixedly connected with the shell, the fixing frame is fixed to the bottom end of the elastic piece, the top end of the elastic piece is fixed to the top plate, the top plate and the base plate are fixed through the fixing piece penetrating through the fixing frame, and the bearing device is high in working efficiency and adaptability.

Description

technical field [0001] The invention relates to the technical field of special automobile assembly equipment, in particular to a carrying device and a special automobile assembly production line. Background technique [0002] The statements herein merely provide background information related to the present invention and do not necessarily constitute prior art. [0003] At present, due to its complex structure, many systems involved, and the characteristics of multi-variety and small-batch production, the assembly process of special vehicles mostly adopts fixed-station assembly lines. The device used for fixing the frame is the bearing device of the entire special vehicle assembly process and the basis for ensuring the normal assembly of the vehicle. The strength, stiffness and height of the bearing device are directly related to whether the chassis can be assembled smoothly. It is a fixed-station assembly line for special vehicles. an essential component. [0004] The inv...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B62D65/02B62D65/18B60B33/06

CPCB62D65/022B62D65/18B60B33/06

Inventor 梁俊涛岳莹莹于善信陈雷纪淑霞李玉成曹刚闫玉红王芬常喜庆卢雪张波刘阳

Owner NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com